Grain fiber wood-like composite material and manufacturing method thereof

The technology of a composite material and a manufacturing method is applied in the manufacturing field of the grain fiber imitation wood composite material, which can solve the problems of good application and achieve the effects of resisting light and heat erosion, increasing its own hardness and rigidity, and achieving good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

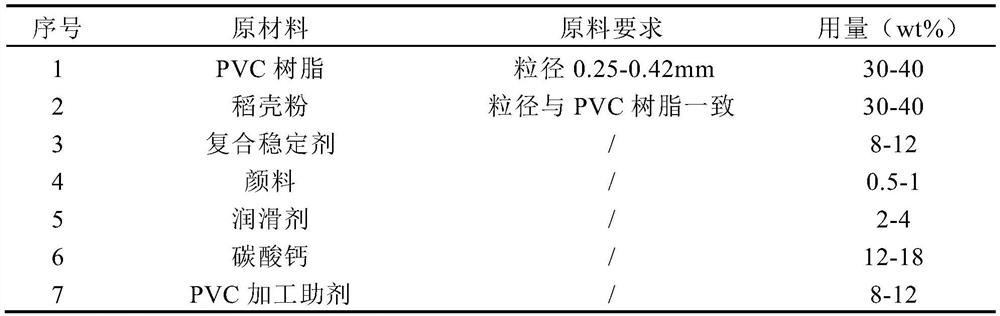

Method used

Image

Examples

Embodiment 1

[0093] Composition for the manufacture of grain fiber wood-like composites comprising: 55% by weight of PVC resin; 6% by weight of impact modifier; 1.5% by weight of processing aids; 2.5% by weight of lubricants; 5% by weight Composite stabilizer; 15% by weight of rice husk powder; 15% by weight of calcium carbonate.

Embodiment 2

[0095] Composition for making grain fiber wood-like composites comprising: 58% by weight of PVC resin; 5% by weight of impact modifier; 1% by weight of processing aid; 2% by weight of lubricant; 4% by weight Composite stabilizer; 15% by weight of rice husk powder; 15% by weight of calcium carbonate.

Embodiment 3

[0097] Composition for making grain fiber wood-like composites comprising: 57% by weight of PVC resin; 5% by weight of impact modifier; 2% by weight of processing aid; 2% by weight of lubricant; 4% by weight Composite stabilizer; 16% by weight of rice husk powder; 14% by weight of calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com