Production method of boron-containing tube-making steel band

A production method and tube steel technology are applied in the production field of boron-containing tube-making steel strip, which can solve the problems of low quality stability of boron-containing tube-making steel strip, long production cycle, poor adaptability, etc., and achieve good shape. , High production efficiency, the effect of reducing the cost per ton of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Technological process: top-bottom double-blown oxygen converter smelting→LF refining→CSP thin slab continuous casting and rolling→cooling→coiling;

[0037] (2) Chemical composition: see Table 1 for chemical composition ratio;

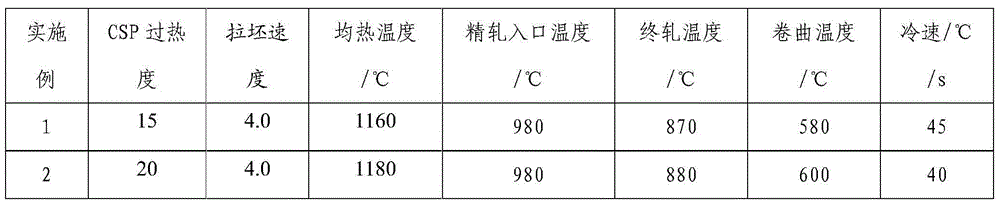

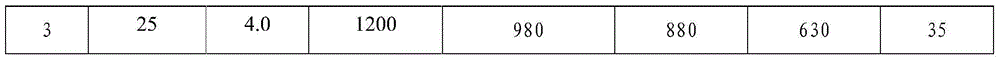

[0038] (3) See Table 2 for CSP continuous casting and rolling process parameters.

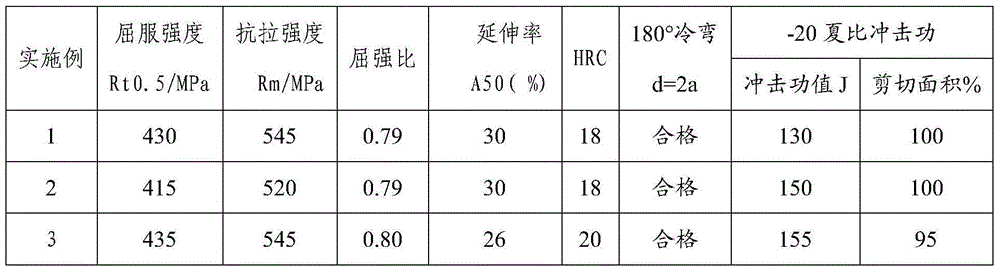

[0039] The mechanical properties of the boron-containing pipe-making steel strip produced in Example 1 are shown in Table 3.

Embodiment 2

[0041] (1) Technological process: top-bottom double-blown oxygen converter smelting→LF refining→CSP thin slab continuous casting and rolling→cooling→coiling;

[0042] (2) Chemical composition: see Table 1 for chemical composition ratio;

[0043] (3) See Table 2 for CSP continuous casting and rolling process parameters.

[0044] The mechanical properties of the boron-containing pipe-making steel strip produced in Example 2 are shown in Table 3.

Embodiment 3

[0046] (1) Technological process: top-bottom double-blown oxygen converter smelting→LF refining→CSP thin slab continuous casting and rolling→cooling→coiling;

[0047] (2) Chemical composition: see Table 1 for chemical composition ratio;

[0048] (3) See Table 2 for CSP continuous casting and rolling process parameters.

[0049] The mechanical properties of the boron-containing pipe-making steel strip produced in Example 3 are shown in Table 3.

[0050] The chemical composition of the boron-containing pipe-making steel strip of Embodiment 1-3 of the present invention is shown in Table 1, the process parameters of Embodiment 1-3 are shown in Table 2, the mechanical properties of Embodiment 1-3 are shown in Table 3, and the product thickness specifications are respectively 5.0, 7.9 and 12.5mm.

[0051] Table 1 Example 1-3 Chemical composition of boron-containing pipe steel strip (wt%)

[0052] serial number

B

C

Si

mn

P

S

N

Ti

als

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com