Extrusion forming die for aluminum flat wire production and processing

A technology of extrusion molding and aluminum flat wire, which is applied in the field of aluminum flat wire processing molds, can solve the problems of unequal cooling speed, affecting the forming effect, and unable to clean the aluminum flat wire, so as to achieve wide coverage, reduce waste, and cool down the forming process uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

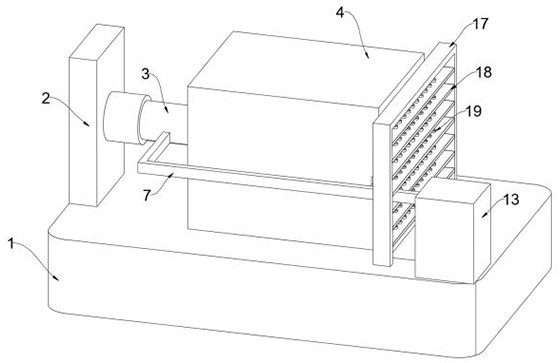

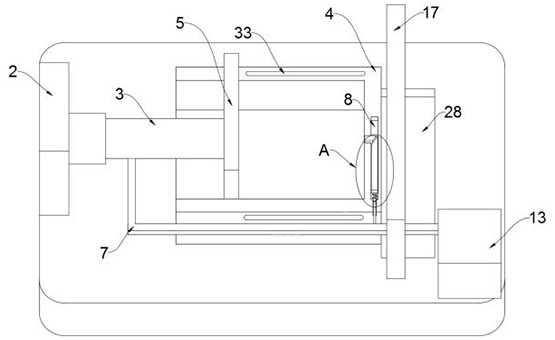

[0030] Embodiment one: with reference to Figure 1-5 , an extrusion molding die for production and processing of aluminum flat wires, including a base 1, characterized in that a support plate 2 is installed and fixed on the base 1, and an extrusion mechanism is fixedly connected to the side wall of the support plate 2;

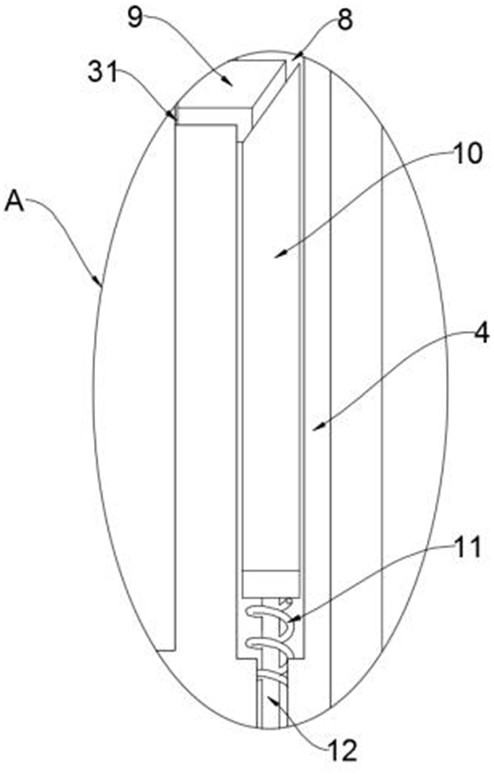

[0031] The extrusion mechanism includes a hydraulic cylinder 3 fixedly connected to the side wall of the support plate 2, a processing box 4 is fixedly connected to the base 1, a plurality of extrusion holes 6 are provided on the side wall of the processing box 4, and an extrusion hole 6 is sealed and slidably connected in the processing box 4. The pressing plate 5, the extruding plate 5 and the movable end of the hydraulic cylinder 3 are fixedly connected, the inner wall of the processing box 4 is provided with a convex groove 8, and the first wedge block 10 is slidingly connected in the convex groove 8, and the inner wall of the convex groove 8 is provided wi...

Embodiment 2

[0042] Embodiment two: with reference to Figure 6-7 The difference between the present embodiment and the first embodiment is that the side wall of the L-shaped rod 7 is fixedly connected with the first rack 20, the top wall of the base 1 is rotatably connected with the rotating rod 21, and the rotating rod 21 is fixedly connected with the first gear 32, The first gear 32 is engaged with the first rack 20, and the rotating rod 21 is fixedly connected with the one-way bearing 22, and the outer ring of the one-way bearing 22 is fixedly connected with the second gear 23, and the one-way bearing 22 can be freely rotated in one direction. A bearing that rotates while locking in the other direction.

[0043] The inner wall of the processing box 4 close to the rotating rod 21 is provided with an empty slot 26, the inner wall of the empty slot 26 is slidingly connected with a second rack 25, the top wall of the base 1 is fixedly connected with a bracket 24, and the second rack 25 is ...

Embodiment 3

[0046] Embodiment three: with reference to Figure 8 The difference between this embodiment and the second embodiment is that the side wall of the movable end of the hydraulic cylinder 3 is fixedly connected with a folding rod 29, and the end of the folding rod 29 away from the hydraulic cylinder 3 is fixedly connected with an auxiliary frame 30, and the auxiliary frame 30 consists of a vertical plate and Composed of multiple horizontal plates.

[0047] When the movable end of the hydraulic cylinder 3 is in motion, it drives the folding rod 29 and the auxiliary frame 30 to move synchronously, thereby synchronously supporting the extruded aluminum flat wire through the folding rod 29 and the auxiliary frame 30, so that the aluminum flat wire is extruded During the process, it is supported by the auxiliary frame 30 to avoid bending due to its own gravity, which is inconvenient for subsequent collection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com