Method and device for measuring COD (Chemical Oxygen Demand) of high-chlorine water sample

A measuring device and measuring method technology, applied in separation methods, chemical instruments and methods, color/spectral characteristic measurement, etc., can solve the problems of unstable measurement, inaccurate testing of high-chlorinated water samples, easy crystallization, etc., and achieve stable measurement Reliable, the effect of improving the adaptability of the water body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

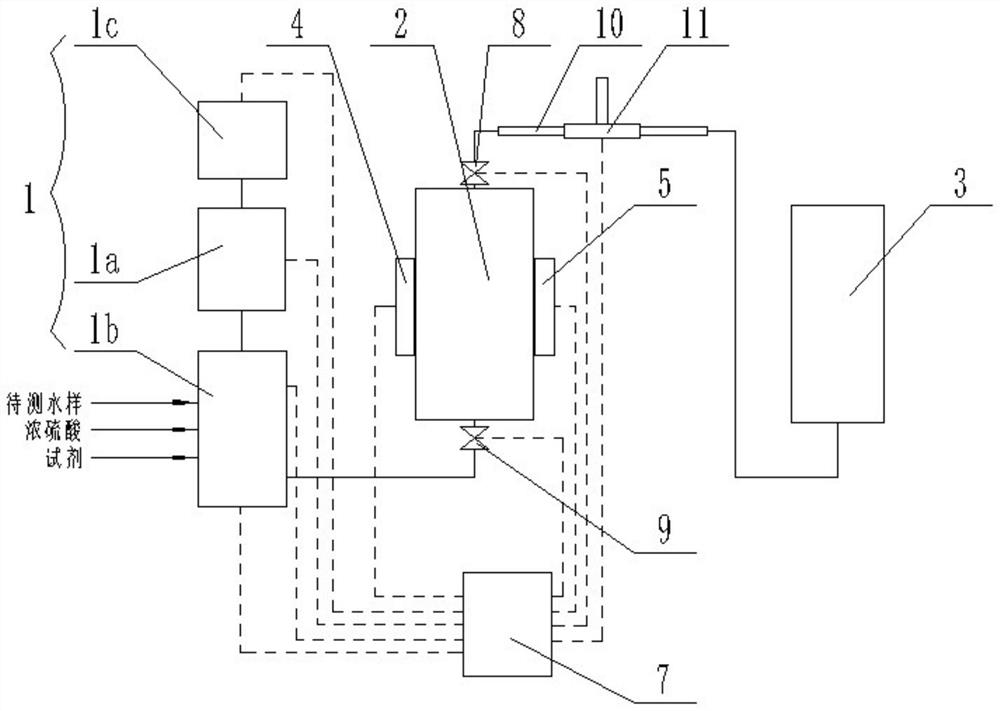

[0032] Such as figure 1 As shown, a COD measuring device for high-chlorinated water samples includes a peristaltic pump 1c, a quantitative tube 1a, a multi-row valve 1b, a reaction unit 2, and an absorption device 3 that are sequentially connected by pipelines. The two ends of the quantitative tube 1a are respectively connected to The peristaltic pump communicates with the multi-row valve 1b, the quantitative tube 1a is provided with a liquid level sensor, the reaction unit 2 is a closed reaction chamber, and the top and bottom of the reaction chamber are respectively equipped with an upper sealing valve 8 and a lower sealing valve. The sealing valve 9, the upper sealing valve 8 communicates with the absorption device 3 through a pipeline one 10, the pipeline one 10 is provided with a three-way valve 11, and the lower sealing valve 9 communicates with the multi-row valve through a pipeline two 1b connection, the reaction unit 2 is provided with a constant temperature heating d...

Embodiment 2

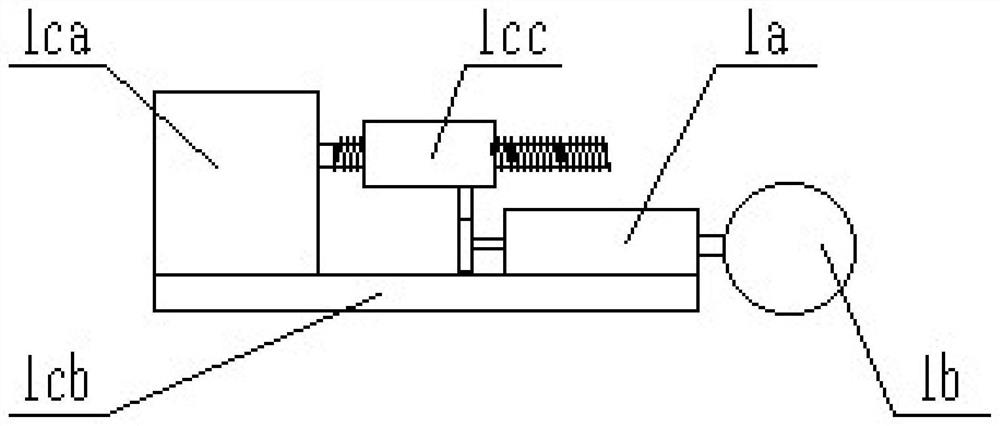

[0034] Such as figure 1 with figure 2 As shown in , a COD determination device for high chlorine water samples includes a syringe 1a, a disc valve 1b, a reaction unit 2 and an absorption device 3 connected in sequence, the pneumatic device 1c includes a motor 1ca and a piston 1cb, and the Both the syringe 1a and the motor 1ca are fixedly arranged on the bracket 1cb, the output shaft of the motor 1ca is fixedly connected with a screw rod, and the screw rod is screwed with a slider 1cc, and the slider 1cc is connected with the piston rod of the syringe. Fixedly connected, the liquid outlet of the syringe communicates with the disc valve 1b, the reaction unit 2 is a closed reaction chamber, the top and bottom of the reaction chamber are respectively equipped with an upper sealing valve 8 and a lower sealing valve 9, so The upper sealing valve 8 communicates with the absorption device 3 through a pipeline one 10, the pipeline one 10 is provided with a three-way valve 11, the low...

Embodiment 3

[0036] A water sample measuring method of a COD measuring device for a high-chlorinated water sample is carried out according to the following steps:

[0037] Step 1. The peristaltic pump 1c continues to rotate forward to generate negative pressure. At this time, open a valve in the multi-row valve 1b, so as to pump the water sample to be tested from the connected pipeline to the quantitative tube 1a, and sense the rising of the pumping through the sensor Stop the pump at a specific point to complete the quantification of a specific volume of the solution. Then, the multi-row valve 1b closes all valves, opens the upper sealing valve 8 and the lower sealing valve 9, the peristaltic pump 1c reverses, and the quantitative pipe 1a A positive pressure will be generated, which can push the water sample to be tested in the quantitative tube 1a to the reaction chamber 2;

[0038] Step 2. The peristaltic pump 1c continues to rotate forward to generate negative pressure. At this time, ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com