Glass tube fixed-length cutting equipment

A technology for cutting equipment and glass tubes, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of difficulty in adapting to automated production requirements and high degree of manual intervention, reducing the risk of fragmentation and achieving a high degree of automation , The effect of improving production efficiency and qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-7 The application is described in further detail.

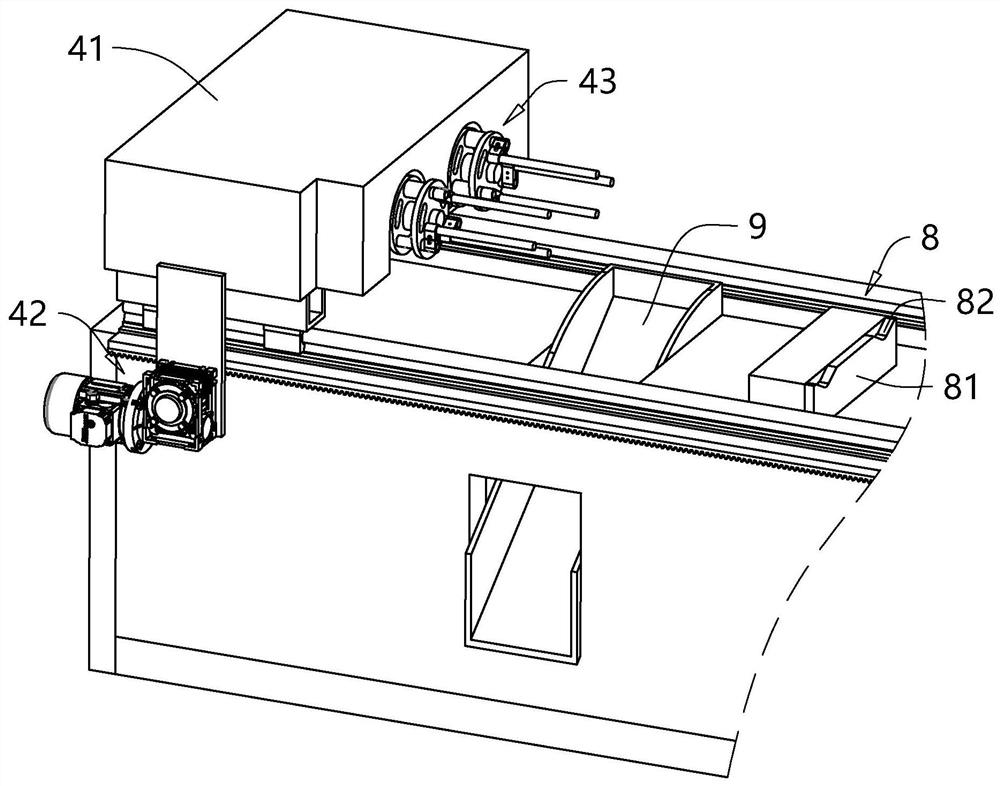

[0044] The embodiment of the present application discloses a glass tube fixed-length cutting device. refer to figure 1 The glass tube fixed-length cutting equipment includes a cutting table 1, a feeding mechanism 2 and a feeding mechanism 3 arranged on the side of the cutting table 1, and a driving clamping mechanism 4 and a fire-spraying mechanism 5 are sequentially arranged on the cutting table 1 along its length direction. And the cutter mechanism 6, the driving clamping mechanism 4 and the cutter mechanism 6 can reciprocate and slide relative to the length direction of the cutting table 1, and the driving clamping mechanism 4 is used to clamp one end of the glass tube and can drive the glass tube along the It rotates in the direction of its own axis, and the cutter mechanism 6 is used to cooperate with the drive clamping mechanism 4 to carve an annular groove on the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com