Carbon-coated nickel-manganese binary cobalt-free positive electrode material, preparation method thereof and lithium ion battery

A positive electrode material and carbon coating technology, applied in the field of lithium ion battery positive electrode material preparation, can solve the problems of poor uniformity, easy to fall off nickel-manganese binary cobalt-free positive electrode material electrochemical performance, poor stability of coating material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

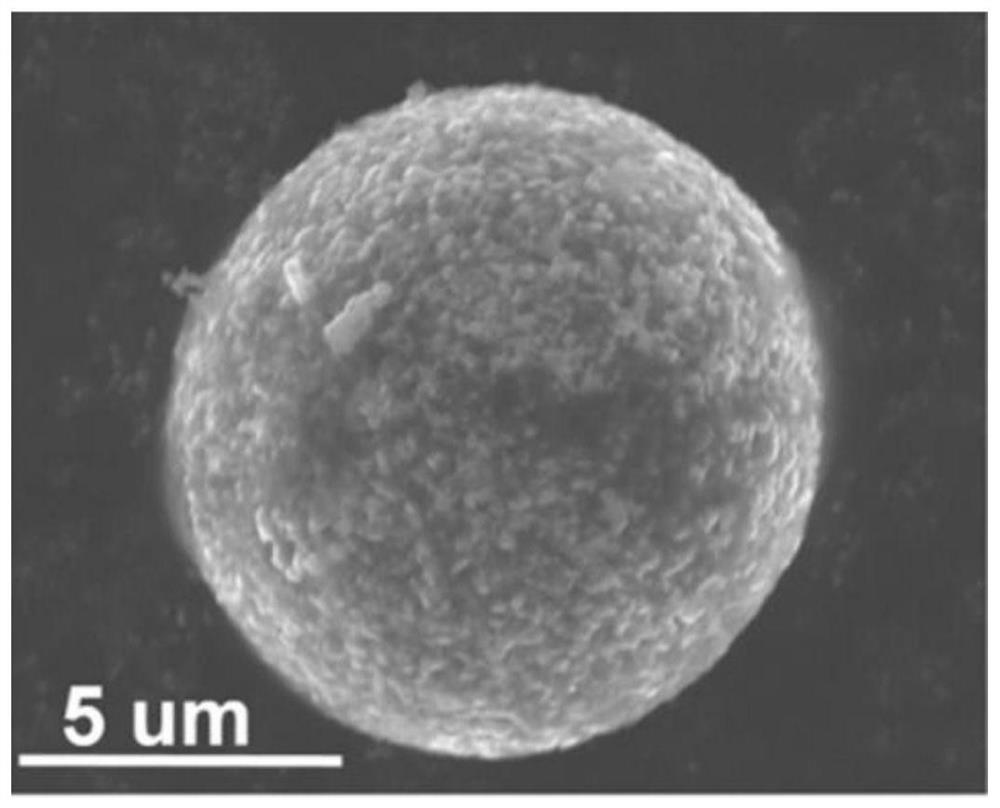

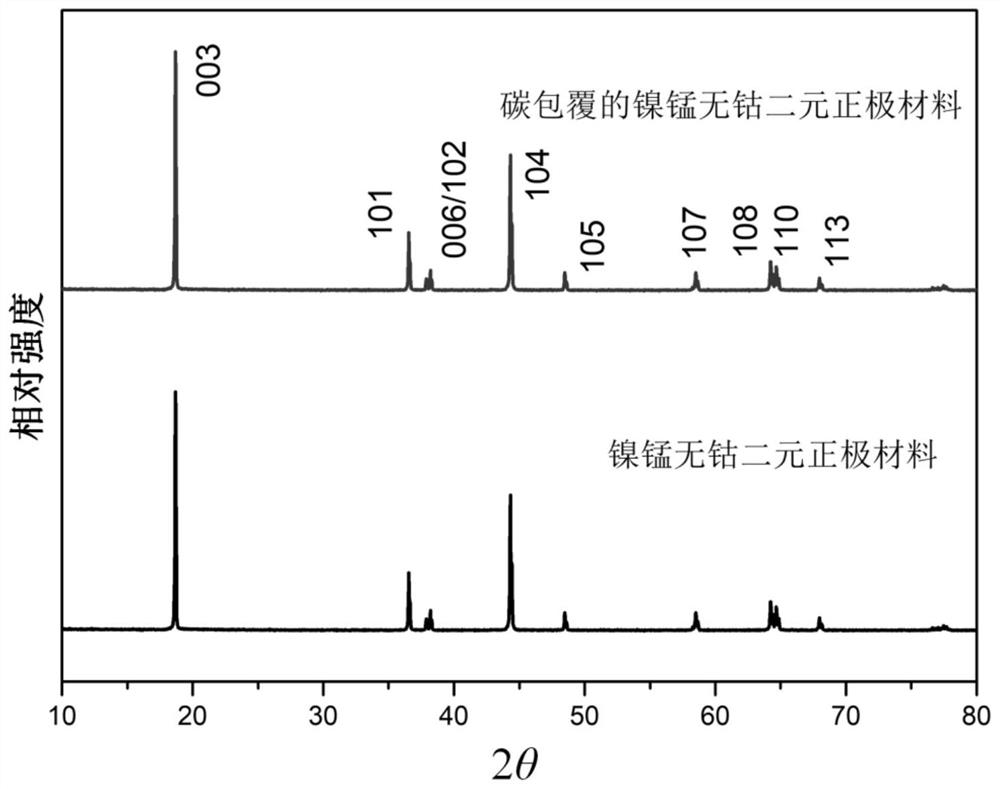

[0023] As described in the background technology, the existing carbon-coated nickel-manganese binary cobalt-free positive electrode material has poor uniformity, poor stability and easy to fall off, and the carbon-coated nickel-manganese binary cobalt-free positive electrode material The problem of poor chemical performance. In order to solve the above-mentioned technical problems, the application provides a method for preparing a carbon-coated binary positive electrode material. The preparation method of a carbon-coated nickel-manganese binary cobalt-free positive electrode material includes: replacing the matrix, graphene and solvent with ions For solvothermal reaction, the ion exchange matrix adopts the general formula MO n and / or M(OH) n , to obtain a solution containing the hydroxide / graphene composite, the K of the hydroxide sp is (1×10 -40 )~(1×10 -11 ), wherein, M is selected from Group IIA, Group IIIA, Group IVA, Group IIIB, Group IVB, Group VIB, Group VIIB or Gro...

Embodiment 1

[0055] A method for preparing a carbon-coated nickel-manganese binary cobalt-free positive electrode material comprises:

[0056] (1) Weigh graphene (made by the preparation method of graphene above) and disperse graphene in pure water. Mg(OH) 2 Mix with prepared graphene solution and stir at 300rpm / min stirring speed. During the above mixing process, Mg(OH) 2 , The weight ratio of graphene to water is 100:1:500.

[0057] (2) Add the above mixture into the reaction kettle, put the reaction kettle into an oven for solvothermal reaction, set the temperature of the solvothermal reaction to 200°C, and the reaction pressure to about 0.8MPa. solution of the compound / graphene composite.

[0058] (3) Mix the nickel-manganese binary precursor and lithium hydroxide evenly (the molar ratio of Li:(Ni+Mn) is 1.04:1), and put it into an oxygen atmosphere furnace (oxygen content ≥ 98%) for calcination , the heating rate was set at 2°C / min, kept at 750°C for 10h, then cooled with the fur...

Embodiment 2

[0064] The difference with embodiment 1 is: the hydroxide that adopts is Zr(OH) 2 , and Zr(OH) in step (1) 2 1. The weight ratio of graphene to water is 100:1:1000; the temperature of the solvothermal reaction in step (2) is 220°C, and the solvothermal time is 12h; in the step (5), stand still for 6h for ion exchange.

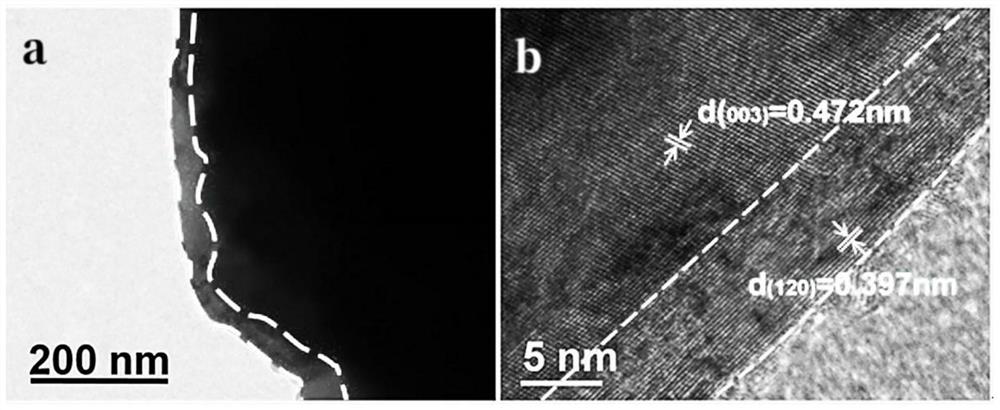

[0065] The obtained carbon-coated nickel-manganese binary cobalt-free cathode material (LiNi 0.75 mn 0.25 o 2 The amount of carbon coating in @C) is 1 wt%, and the thickness of the carbon coating layer is 4 nm. The electrochemical performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com