Preparation method of chalcogenide tubular material

A chalcogenide, tubular technology, used in the preparation of sulfide/polysulfide, tin compounds, chemical instruments and methods, etc., can solve the problems of large specific surface area of tubular materials, poor transport and separation of photogenerated carriers, etc. To achieve the effect of compact structure, environmentally friendly process, and accelerated transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

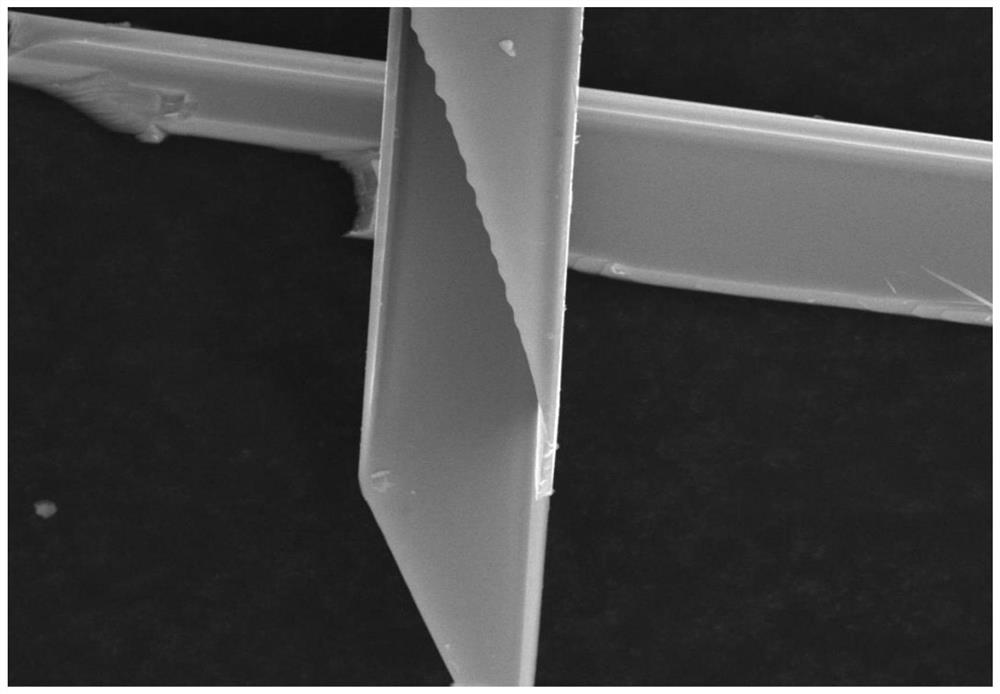

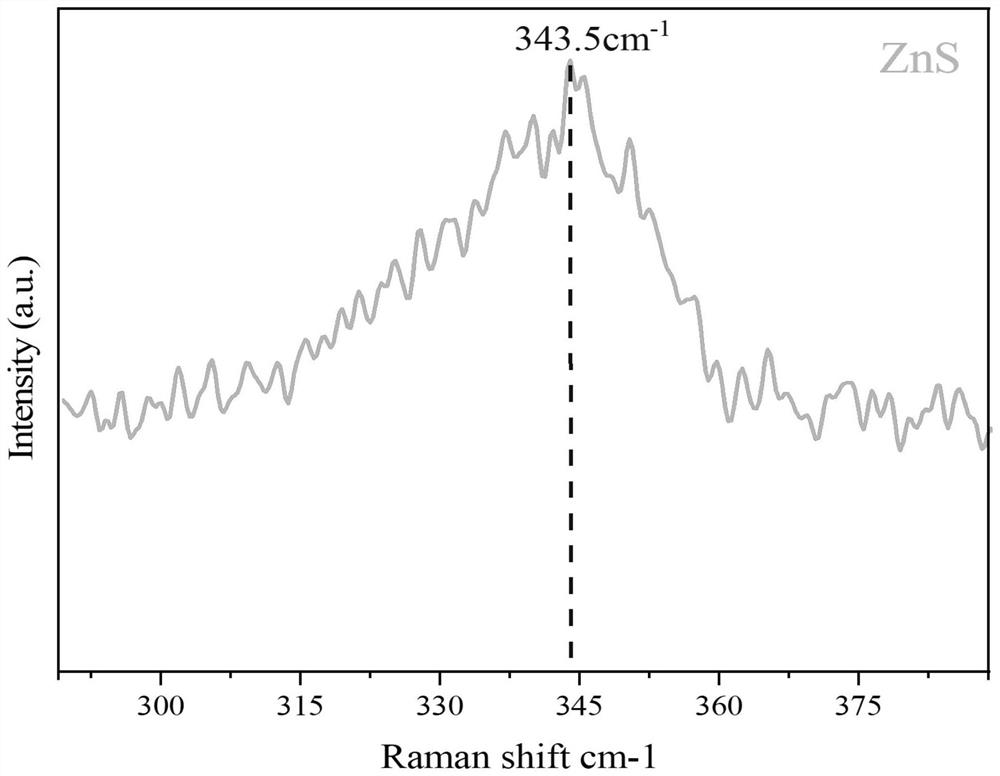

[0036] Embodiment 1: In this embodiment, a tube furnace with dual temperature zones is used to prepare ZnS tubular material;

[0037] A kind of preparation method of ZnS tubular material, concrete steps are as follows:

[0038](1) Place 0.4mol sublimated sulfur (99.9% in purity) in the low-temperature heating zone of a dual-temperature zone tube furnace, and place 0.2mol metallic zinc powder in the high-temperature vulcanization heating zone of a dual-temperature zone tube furnace; wherein the metal zinc Powder purity ≥ 98%;

[0039] (2) Turn on the vacuum pump, pump the pressure in the reaction system to 10Pa and below, then close the pumping valve, open the intake valve, fill in high-purity argon (purity is 99.99%) until the pressure gauge is 100KPa and close Inlet valve, open the inlet valve to re-pump the pressure in the reaction system to 10Pa or below, repeat the gas washing three times to exhaust the impurity gas in the system, and avoid the formation of oxide impuriti...

Embodiment 2

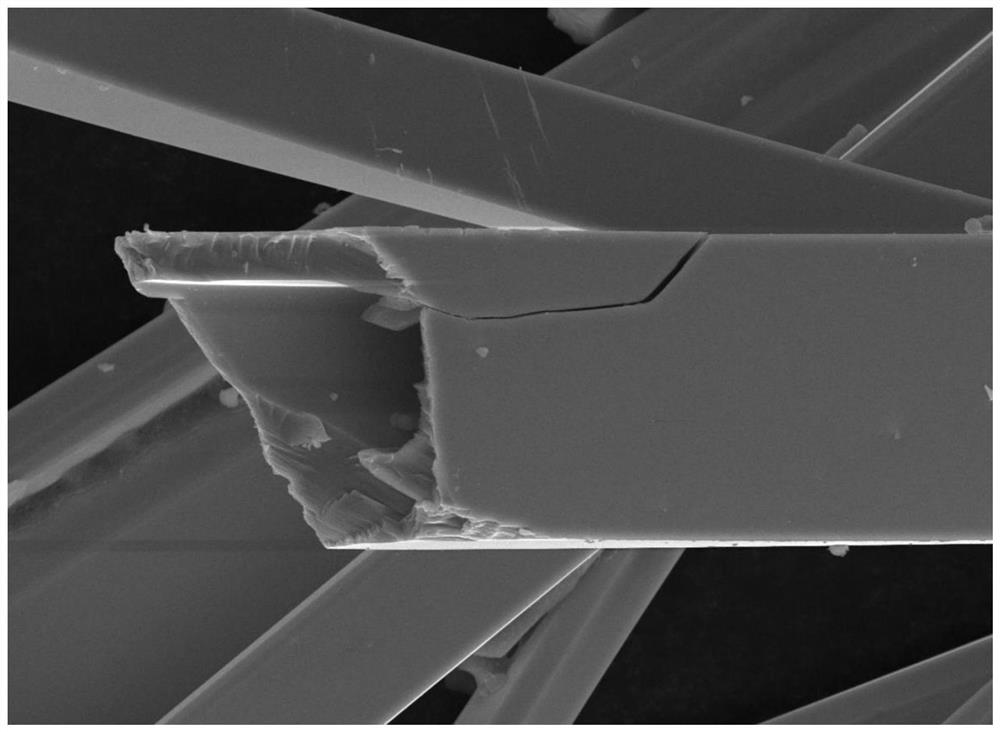

[0043] Embodiment 2: This embodiment adopts double-temperature zone vertical furnace to prepare tin sulfide tubular material;

[0044] A kind of preparation method of tin sulfide tubular material, concrete steps are as follows:

[0045] (1) 1.0mol sublimated sulfur (purity is 99.9%) is placed in the low-temperature heating zone of the double-temperature zone vertical furnace, and 0.4mol tin powder is placed in the high-temperature vulcanization heating zone of the double-temperature zone vertical furnace; wherein the tin powder Purity≥98%;

[0046] (2) Turn on the vacuum pump, pump the pressure in the reaction system to 10Pa and below, then close the pumping valve, open the intake valve, fill in high-purity argon (purity is 99.99%) until the pressure gauge is 100KPa and close Inlet valve, open the inlet valve to re-pump the pressure in the reaction system to 10Pa or below, repeat the gas washing three times to exhaust the impurity gas in the system, and avoid the formation of...

Embodiment 3

[0050] Embodiment 3: In this embodiment, a tubular furnace with dual temperature zones is used to prepare antimony selenide tubular material;

[0051] A kind of preparation method of antimony selenide tubular material, concrete steps are as follows:

[0052] (1) 0.8mol selenium powder (purity greater than 99.9%) is placed in the low-temperature heating zone of the dual-temperature zone tube furnace, and 0.3mol metal antimony powder is placed in the high-temperature vulcanization heating zone of the dual-temperature zone tube furnace; wherein metal antimony Powder purity ≥ 98%;

[0053] (2) Turn on the vacuum pump, pump the pressure in the reaction system to 10Pa and below, then close the pumping valve, open the intake valve, fill in high-purity argon (purity is 99.99%) until the pressure gauge is 100KPa and close Inlet valve, open the inlet valve to re-pump the pressure in the reaction system to 10Pa or below, repeat the gas washing three times to exhaust the impurity gas in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com