Printing and dyeing dust remover

A dust collector and dust collection technology, applied in the field of printing and dyeing, can solve the problems of polluting the surrounding environment and physical damage of operators, and achieve the effects of improving the workshop environment, increasing vibration, and protecting physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

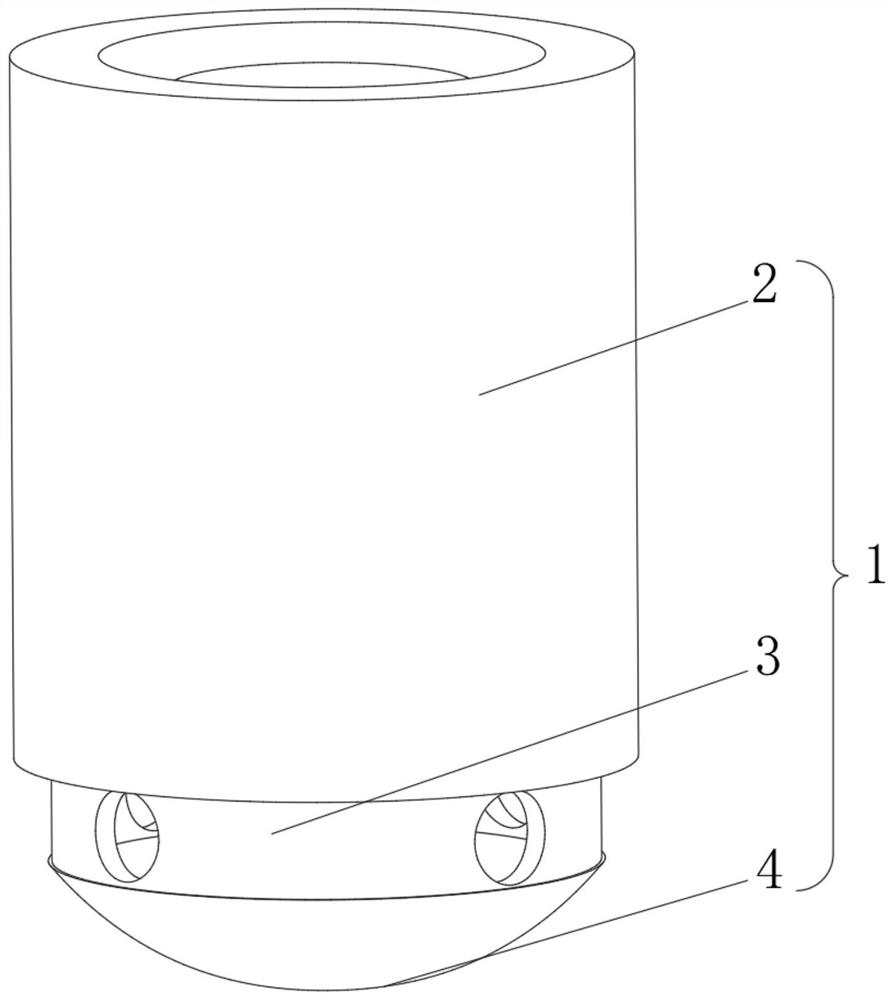

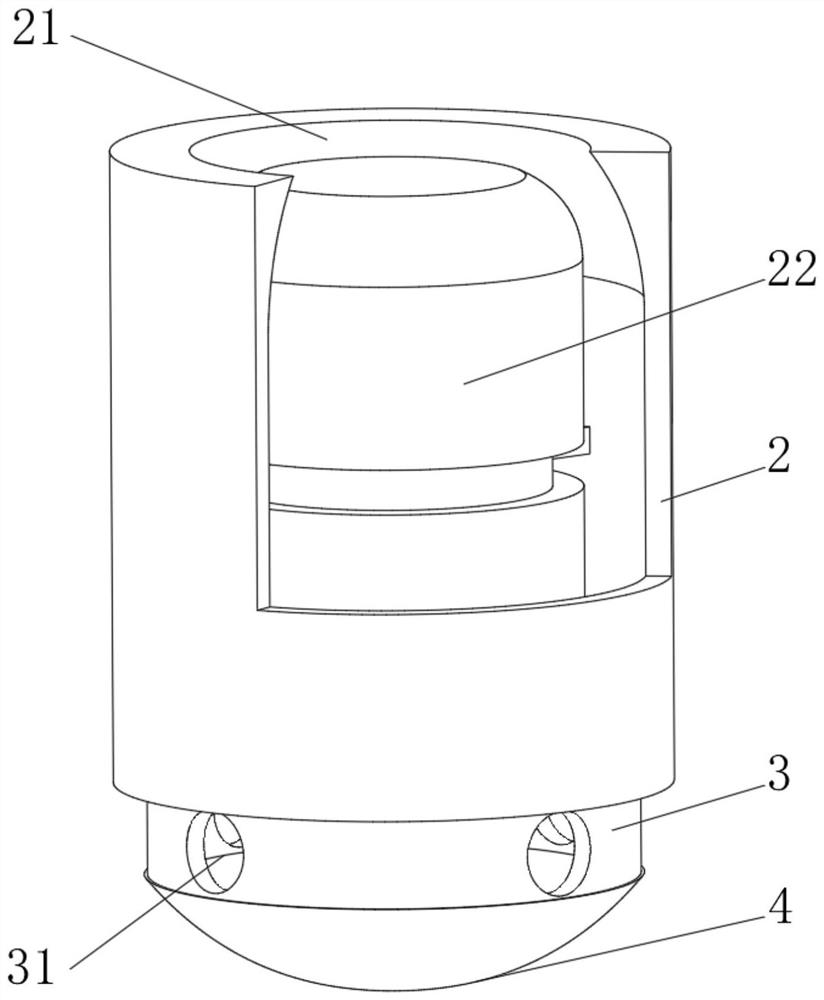

[0035] see Figure 1-3 , the present invention provides a technical solution: a printing and dyeing dust collector, including a printing and dyeing dust collector body 1 composed of a dust removal shell 2, an air intake plate 3 and a dust collection shell 4, the bottom of the dust removal shell 2 is fixed to the top of the air intake plate 3 connection, the bottom of the air intake plate 3 is threadedly connected to the top of the dust collection case 4, the top of the dust removal case 2 is provided with an air outlet 21, the interior of the dust removal case 2 is provided with a filter mechanism 22, and the interior of the air intake plate 3 is provided with an air intake port 31, the filter mechanism 22 includes a filter housing 221, the inside of the filter housing 221 is slidably connected to a limit block 222 by a spring, the side of the limit block 222 away from the filter shell 221 is slidably connected to the inside of the dust removal shell 2, and the bottom of the fi...

Embodiment 2

[0041] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: the shaker 223 includes a shaker plate 2231, the top of the shaker plate 2231 is rotationally connected with the bottom of the filter housing 221 through a reset piece, and the right side of the shaker plate 2231 is fixedly connected Rocking ball 2232 is arranged, and the right side of shaking ball 2232 is provided with cam 2233, and the outside of cam 2233 is fixedly connected with projection 2234, and the inside of projection 2234 is fixedly connected with the inside of dust removal case 2 by rotating rod.

[0042] The counterweight 227 comprises a counterweight ring 2271, the bottom of the counterweight ring 2271 is fixedly connected to the top of the windshield 226, the inside of the counterweight ring 2271 is provided with a water storage bag 2272, and the bottom of the water storage bag 2272 is connected to the shield by an elastic rod. The inside of the air plate 22...

Embodiment 3

[0045] see Figure 1-6 , On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the suction device 225 includes a suction frame 2251, and the interior of the suction frame 2251 is respectively provided with a first magnetic block 2252 and a second magnetic block 2253, the right side of the first magnetic block 2252 is fixedly connected to the left side of the second magnetic block 2253 through a string.

[0046] The suction frame 2251 is fixedly connected with an elastic ring 2254, and the side of the elastic ring 2254 away from the suction frame 2251 is fixedly connected with a folding plate 2255, and the outside of the folding plate 2255 is slidingly connected with the outside of the rotating rod. The side is rotationally connected with the bottom end of the rotating rod through the rotating seat, and the right side of the second magnetic block 2253 is rotationally connected with the bottom end of the rotating rod through the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com