Modified yellow light absorber, yellow-light-proof adhesive, yellow-light-proof adhesive tape and preparation method of modified yellow light absorber

A technology of absorbents and adhesives, applied in the direction of adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve problems affecting product performance, affecting visual effects, and poor compatibility with polymer adhesives , to achieve the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

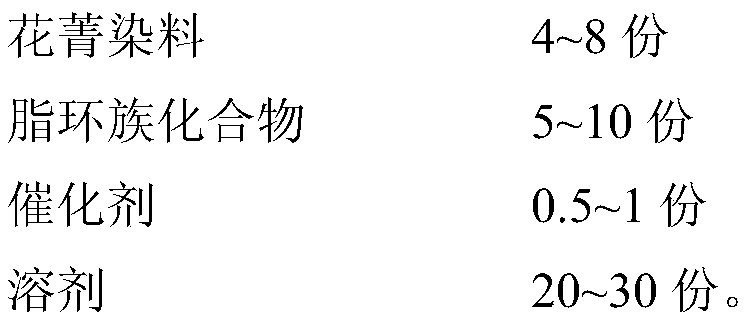

[0031] (1) Add 4 parts of dimethylcyanine, trimethylcyanine (mass ratio 1:2), 5 parts of N-ethylmorpholine, 20 parts of acetone, and 0.5 parts of dibutyltin dilaurate into a three-necked flask Mix evenly, sonicate at 40°C for 30 minutes, react under magnetic stirring for 3 to 4 hours, filter and dry in vacuum to obtain the modified yellow light absorber;

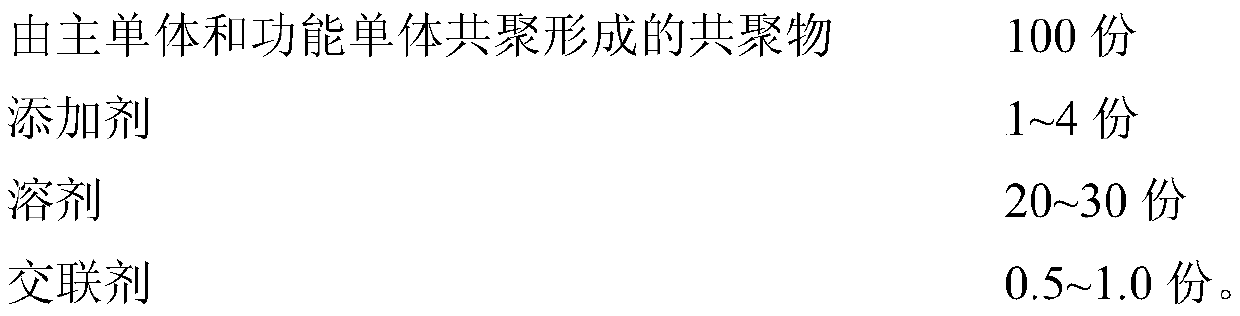

[0032] (2) Add the modified yellow light absorber prepared above and 1 part of meta-tetra-p-benzenesulfonate porphyrin zinc into 30 parts of toluene, stir the solvent completely at 40°C to 60°C, and then dissolve the above solution Add to 100 parts of SK-1502D, stir for half an hour, and finally add 0.7 parts of Y-75 and stir for 20 minutes to obtain an anti-yellowing adhesive;

[0033] (3) Apply the anti-yellow light adhesive composition prepared above evenly on the release film, the thickness of the coating is 20 μm, dry it in an 85°C drying oven for 2 minutes, and then attach it to the PET black film. Roll, the first eng...

Embodiment 2

[0036] (1) Add 8 parts of dimethylcyanine, trimethylcyanine (mass ratio 1:2), 10 parts of N-ethylmorpholine, 25 parts of acetone, and 0.5 parts of dibutyltin dilaurate into a three-necked flask Mix evenly, sonicate at 40°C for 30 minutes, react under magnetic stirring for 3 to 4 hours, filter and dry in vacuum to obtain the modified yellow light absorber;

[0037] (2) Add the modified yellow light absorber prepared above and 4 parts of meta-tetra-p-benzenesulfonate porphyrin zinc into 20 parts of toluene, stir the solvent completely at 40°C to 60°C, and then dissolve the above solution Add to 100 parts of SK-1502D, stir for half an hour, and finally add 0.5 parts of Y-75 and stir for 20 minutes to obtain an anti-yellowing adhesive;

[0038] (3) Apply the anti-yellow light adhesive composition prepared above evenly on the release film, the thickness of the coating is 20 μm, dry it in an 85°C drying oven for 2 minutes, and then attach it to the PET black film. Roll, the first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com