Electronic welding smoke emission equipment

A fume and equipment technology, which is applied in the field of electronic welding fume discharge equipment, can solve the problems of purifying treatment that cannot be loosened, and achieves the effects of simple structure, injury prevention and absorption assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

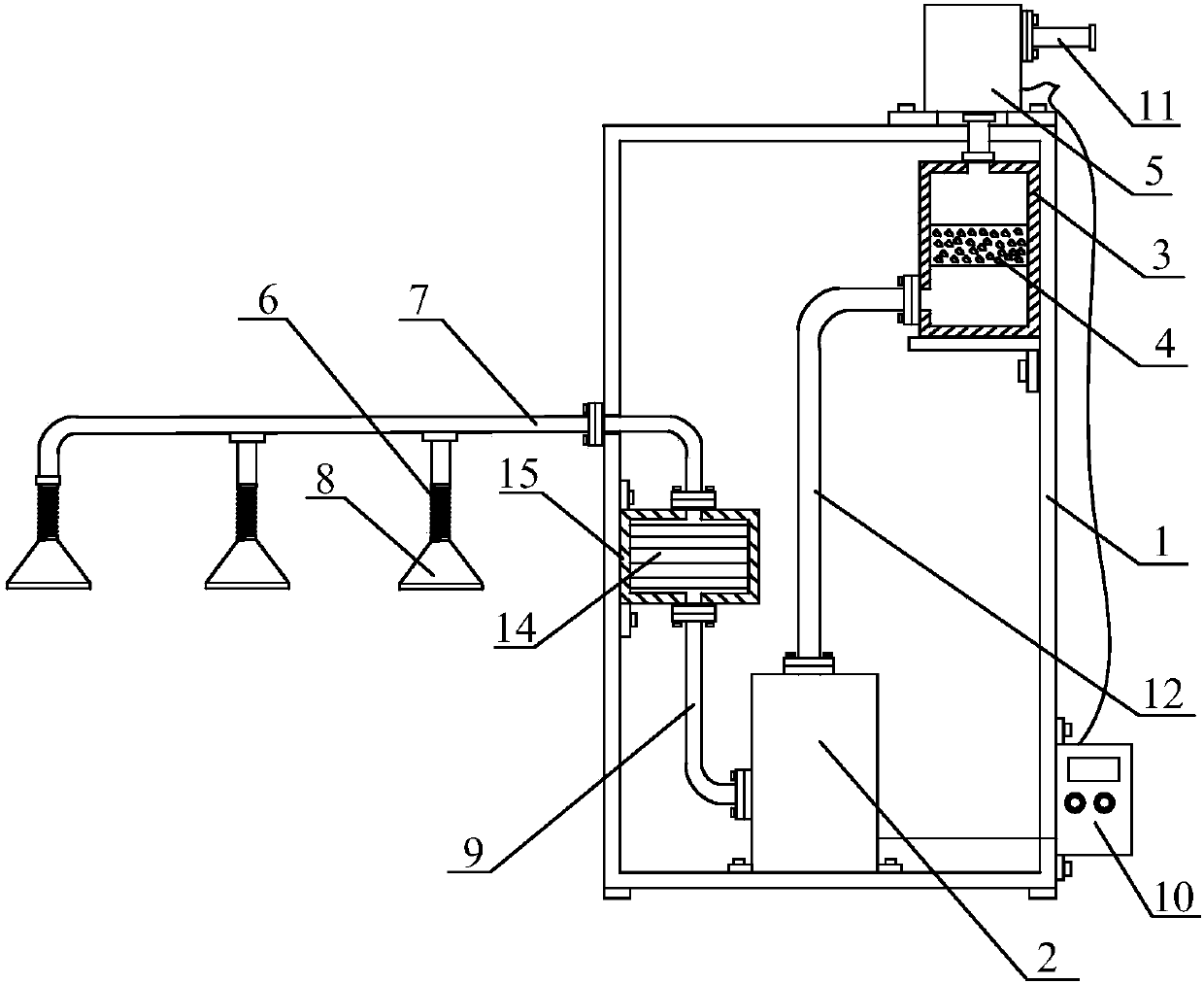

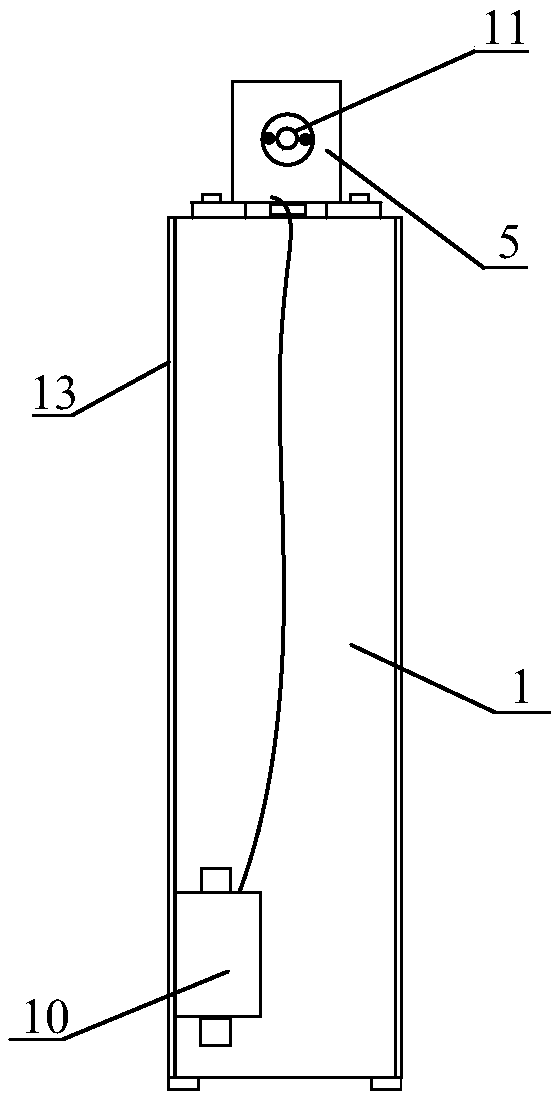

[0021] Such as figure 1 , 2 As shown, the present invention discloses an electronic welding fume discharge device, which includes a bracket 1 , an exhaust fan 2 , a purification tank 3 , an exhaust fan 5 , a fume filter device, an air suction device, and a controller 10 . Wherein, the suction device such as figure 2 As shown, it includes a main pipe 7, a telescopic pipe 6, and a suction hood 8.

[0022] During implementation, the bracket 1 is the support body and the carrier of the whole device, and the front and rear ends of the bracket 1 are respectively provided with cover plates 13, and the bracket 1 and the cover plates 13 cooperate to form a hollow body. This exhaust fan 2 is as the power source of suction device, and this exhaust fan 2 is fixed on the support 1 by screw, and the exhaust fan 2 is connected with the controller 10, and the air inlet of this exhaust fan 2 is provided with the air inlet pipe 9, and its An air passage 12 is also arranged on the air outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com