Preparation method of flexible strip-shaped lithium-carbon dioxide battery positive electrode material and battery

A carbon dioxide and battery positive electrode technology, which is applied to fuel cell half-cells and secondary battery-type half-cells, battery electrodes, circuits, etc., can solve problems such as low energy efficiency, high charging potential, and poor cycle performance. Achieve the effects of simple synthesis process, energy saving, simple preparation and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

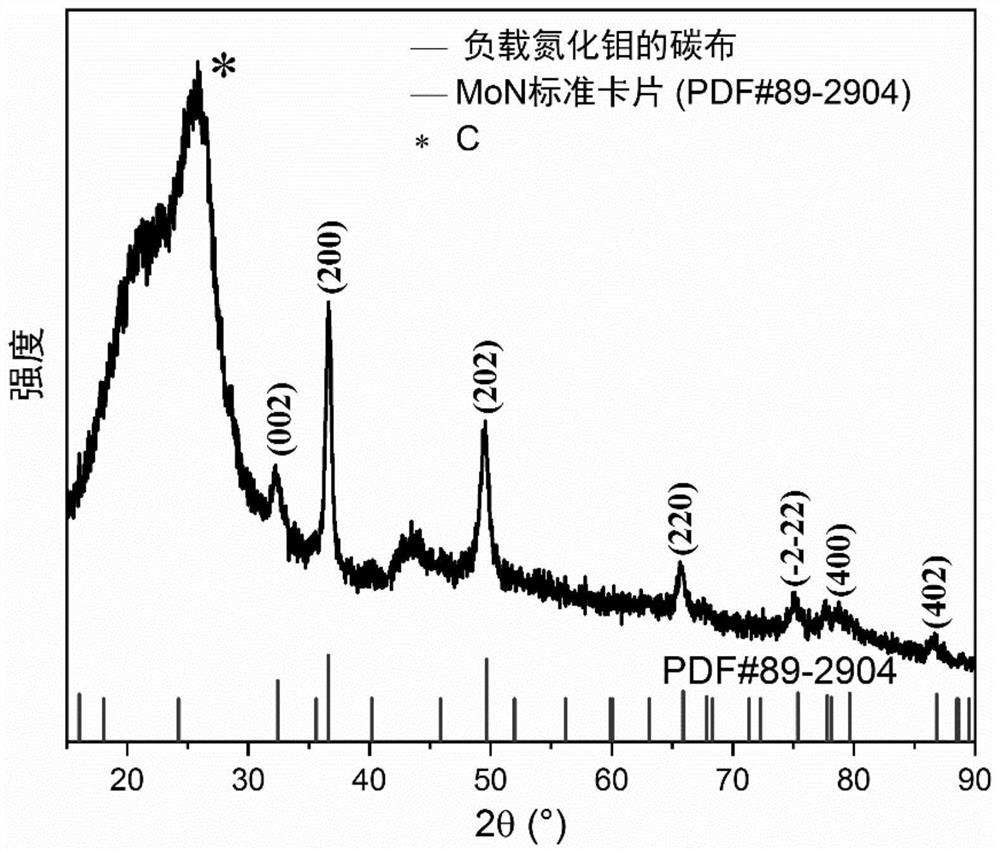

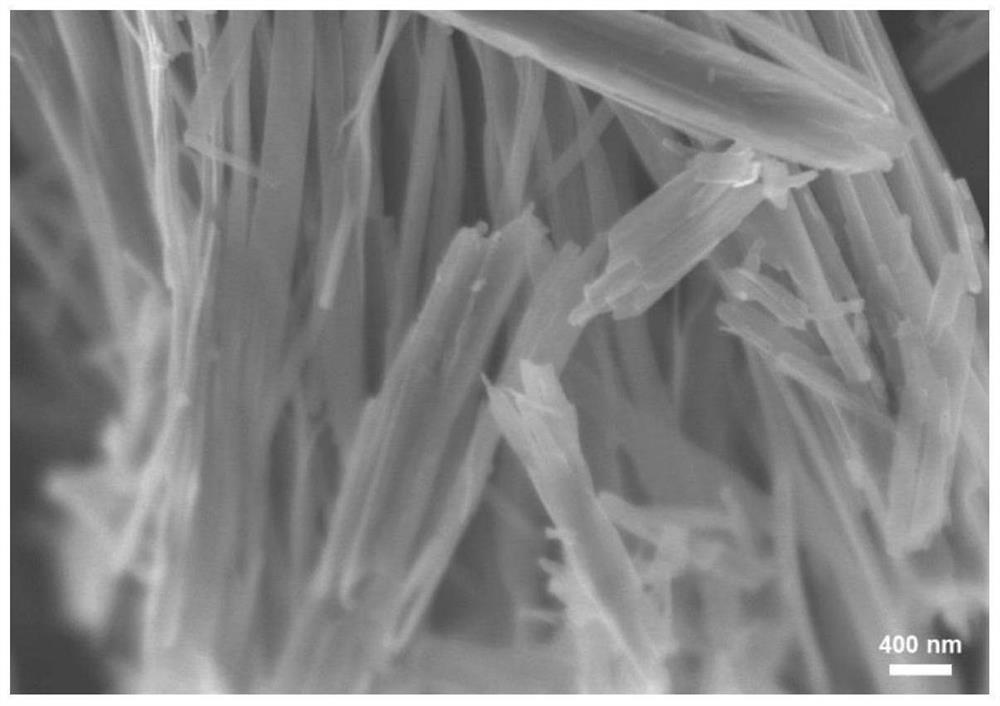

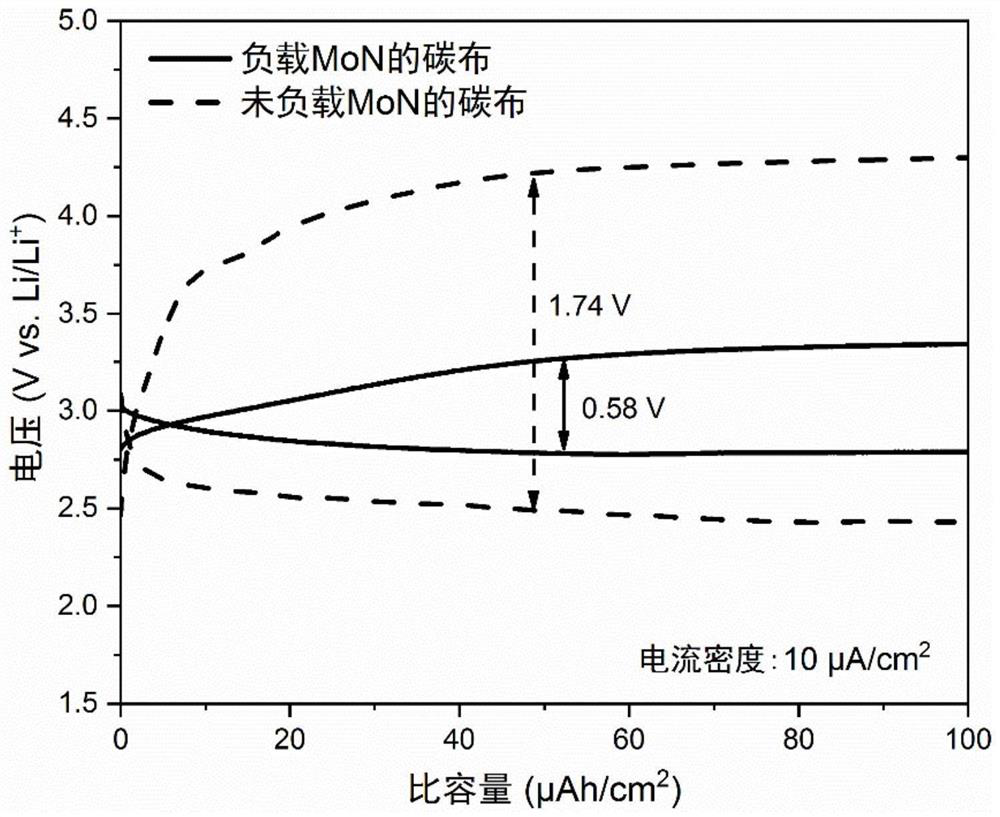

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Ultrasonic wash the carbon cloth with acetone for 0.5h, then ultrasonically wash it with deionized water for 3 times, each washing time is 10min, then immerse it in concentrated nitric acid at room temperature for 0.5h, and then ultrasonically wash it with deionized water for 3 times, each washing time is 10min, and then placed in a blast drying oven at 60°C for drying, and then cut into specifications of 1cm in width and 10cm in length for use.

[0035] Step 2: take by weighing 0.5g ammonium molybdate [(NH 4 )6 Mo 7 o 24 4H 2 O] Add to 10mL deionized water, then slowly add 10mL concentrated nitric acid, stir for 20min, then slowly add 0.3g cetyltrimethylammonium bromide cationic surfactant, stir for 10min until the solution gradually turns yellow, add a tablet Step 1 The treated and cut carbon cloth was impregnated for 10 minutes.

[0036] Step 3: Transfer the mixed solution containing carbon cloth in step 2 into a 50mL digestion tank lined with polytetrafl...

Embodiment 2

[0040] Step 1: ultrasonically wash the carbon cloth with acetone for 1 hour, then ultrasonically wash it with deionized water for 3 times, each washing time is 20 minutes, then immerse it in concentrated nitric acid at room temperature for 1 hour, then ultrasonically wash it with deionized water for 3 times, Wash for 20 minutes each time, then dry in a blast drying oven at 80°C, and then cut into specifications with a width of 1 cm and a length of 8 cm for later use.

[0041] Step 2: take by weighing 0.5g ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 4H 2 O] Add to 20mL deionized water, then slowly add 10mL concentrated nitric acid, stir for 10min, then slowly add 0.3g cetyltrimethylammonium bromide cationic surfactant, stir for 20min until the solution gradually turns yellow, add a tablet Step 1 The treated and cut carbon cloth was impregnated for 20min.

[0042] Step 3: Transfer the mixed solution containing carbon cloth in step 2 into a 50mL digestion tank lined with polytet...

Embodiment 3

[0046] Step 1: ultrasonically wash the carbon cloth with acetone for 1 hour, then ultrasonically wash it with deionized water for 3 times, each washing time is 20 minutes, then immerse it in concentrated nitric acid at room temperature for 1 hour, then ultrasonically wash it with deionized water for 3 times, Wash for 20 minutes each time, then dry in a blast drying oven at 80°C, and then cut into specifications with a width of 1 cm and a length of 8 cm for later use.

[0047] Step 2: take by weighing 0.6g ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 4H 2 O] Add to 20mL deionized water, then slowly add 10mL concentrated nitric acid, stir for 10min, then slowly add 0.3g cetyltrimethylammonium bromide cationic surfactant, stir for 20min until the solution gradually turns yellow, add a tablet Step 1 The treated and cut carbon cloth was impregnated for 20min.

[0048] Step 3: Transfer the mixed solution containing carbon cloth in Step 2 into a 50mL digestion tank lined with polytet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com