Drying equipment for food processing

A technology for drying equipment and food processing, which is applied in lighting and heating equipment, drying, drying machines, etc. It can solve the problems of flying catkins and gas content, achieve good results, increase the wind receiving area, and accelerate the removal of impurities. Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

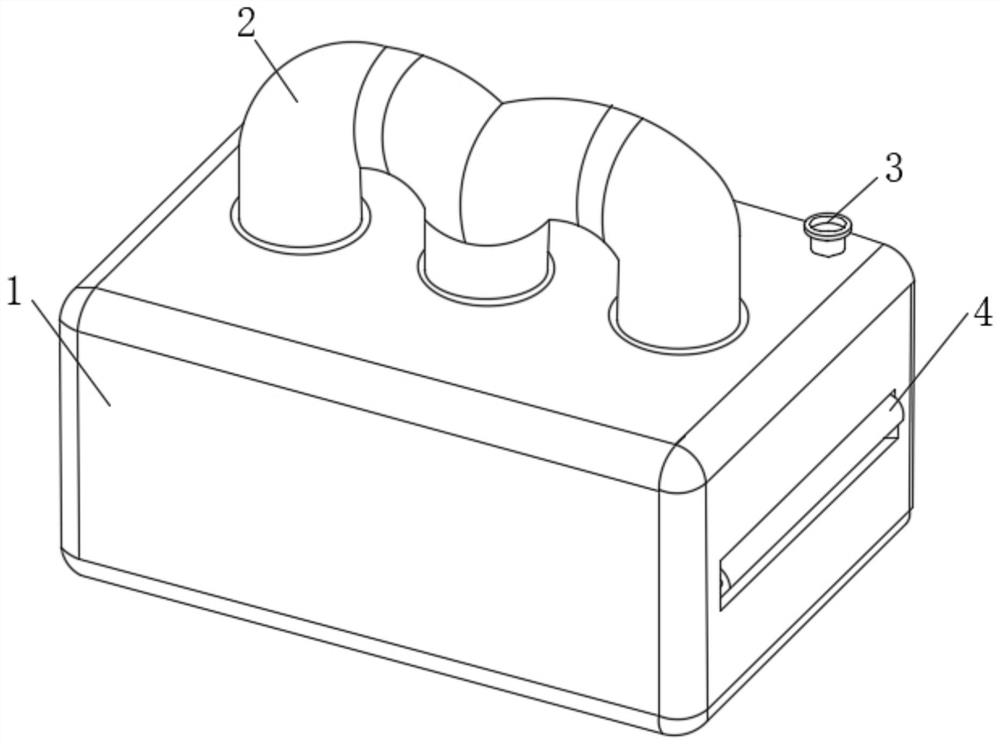

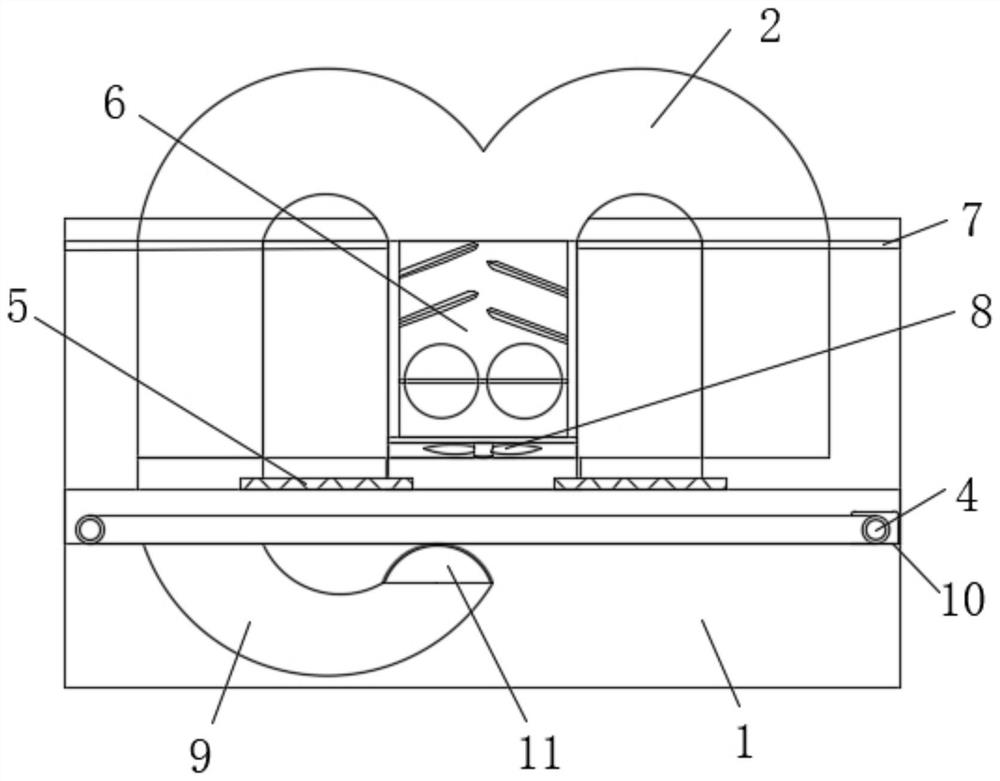

[0032] see Figure 1-2 , the embodiment of the present invention provides a technical solution: a drying equipment for food processing, comprising a drying box 1, the top of the drying box 1 is fixedly connected with a tee pipe 2, and the top of the drying box 1 is fixedly connected with a The water inlet 3 inside the drying box 1 is fixedly connected with a motor 10 on one side of the inside of the drying box 1, and the output end of the motor 10 is movably connected with a transmission track 4 through a rotating shaft, and one end of the tee pipe 2 is fixedly connected with a delivery pipe 9 , the end of the conveying pipe 9 far away from the tee pipe 2 is fixedly connected with an air equalizer 11, the inside of the drying box 1 is fixedly connected with a water inlet pipe 7, the water inlet pipe 7 communicates with the water inlet 3, and the inside of the tee pipe 2 is provided with a gas The processing device 6 and the inside of the drying box 1 are fixedly connected with...

Embodiment 2

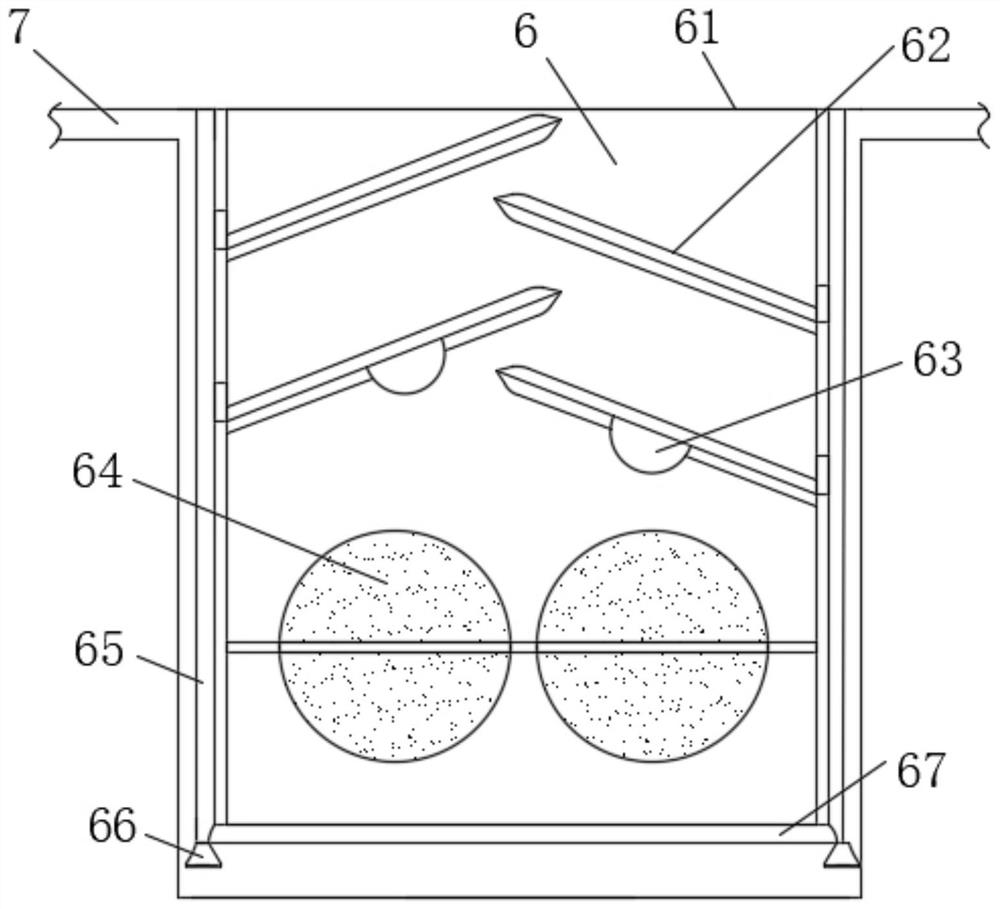

[0035] Such as Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the gas treatment device 6 includes a frame body 61, and a dust collection bin 65 is provided inside the frame body 61, and the bottom of the dust collection bin 65 is fixedly connected with a release Device 66, the inner wall of the frame body 61 is fixedly connected with the first collecting plate 62, the inner wall of the frame body 61 is located at the lower side of the first collecting plate 62 and is fixedly connected with the second collecting plate 63, and the inner wall of the frame body 61 is fixedly connected through the rotating rod Drying transfer plate 64 is arranged.

[0036]Release device 66 comprises conical cover 662, and the outside of conical cover 662 is fixedly connected with arc convex plate 664, and the middle part of conical cover 662 is fixedly connected with 666, and the outside of 666 is fixedly connected with conveying rail 665, a...

Embodiment 3

[0040] Such as Figure 1-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the second collecting plate 63 includes a rubber outer frame 636, and the inside of the rubber outer frame 636 is fixedly connected with a built-in bump 632, and the built-in bump The inside of 632 is rotatably connected with a rotating ring 631, the outer side of the rotating ring 631 is fixedly connected with a wind receiving plate 635, the middle part of the rubber outer frame 636 is fixedly connected with a oscillating grain 634 through an elastic fixture 633, and the inside of the second collecting plate 63 is connected by a spring 638 is movably connected with a connecting fork 639 , and the outer side of the connecting fork 639 is fixedly connected with a percussion post 637 , and the percussion post 637 extends to the inside of the rubber outer frame 636 .

[0041] The water flow channel 663 includes a dust pan a2, and a leakage hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com