Artificial aggregate and preparation process thereof

A technology of artificial aggregate and preparation process, which is applied in the field of artificial aggregate, can solve the problems of insufficient ore materials and poor usability of ore, and achieve the effects of reducing ore mining, facilitating promotion, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of artificial aggregate preparation process, comprises the following steps:

[0029] s1: Mix the raw materials of Aggregate A component at high speed, and mix the raw materials of Aggregate B component at high speed, mix the mixed Aggregate A component and Aggregate B component into a fluid mixture, and mix the fluid dynamic The mixture is poured and spread in the mold. Preferably, the pigment is mixed in the fluid mixture according to the requirements, so that the color of the formed aggregate is more diverse and better meets people's needs;

[0030] s2: Vacuumize the fluid mixture to reduce air bubbles inside the fluid mixture and make the texture of the formed block material more uniform;

[0031] s3: the mixture after vacuuming is heated and solidified;

[0032] s4: Demoulding the cured bulk material;

[0033] s5: The bulk material is sent to the crusher to be crushed into aggregate particles of the required mesh.

[0034] The new resin aggregate of this p...

Embodiment 2

[0037] The whole process is designed in the form of a tunnel kiln. The mixed liquid materials are poured into a rectangular silicone box with a thickness of about two centimeters. The box passes through a heating tunnel and enters a closed vacuum device. The box continues to move forward along the tunnel, heated and solidified, and then flipped and demolded. The solidified block material is sent to the crusher through the belt for crushing.

Embodiment 3

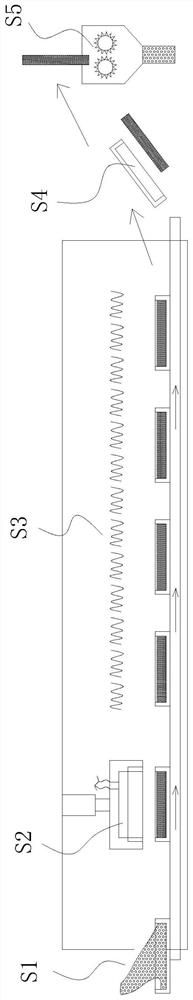

[0039] refer to figure 1 :

[0040] s1: Mix the raw materials of Aggregate A component at high speed, and mix the raw materials of Aggregate B component at high speed, mix the mixed Aggregate A component and Aggregate B component into a fluid mixture, and mix the fluid dynamic The mixture is poured and spread in the mold, the aggregate A component is mixed with the aggregate B component according to the ratio of 1:1, the mold is a rectangular or round silicone box, the top of the silicone box is open, pouring and spreading on the mold The thickness of the fluid mixture inside is 15-30mm, preferably 20mm;

[0041] s2: Vacuumize the fluid mixture to reduce the internal air bubbles of the fluid mixture and make the texture of the formed block material more uniform. The vacuum equipment includes a vacuum machine, which is connected to the suction port of the vacuum machine and can be used up and down. The moving cover, the cover seals the opening of the silicone box, and then in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com