Multifunctional horizontal sterilization kettle

A horizontal kettle, multi-functional technology, applied in the field of multi-functional horizontal sterilizers, can solve the problems of sterilization of materials that cannot be sterilized, sterilizers cannot be directly shared or mixed, etc., to improve applicability and ensure heat. effect of radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

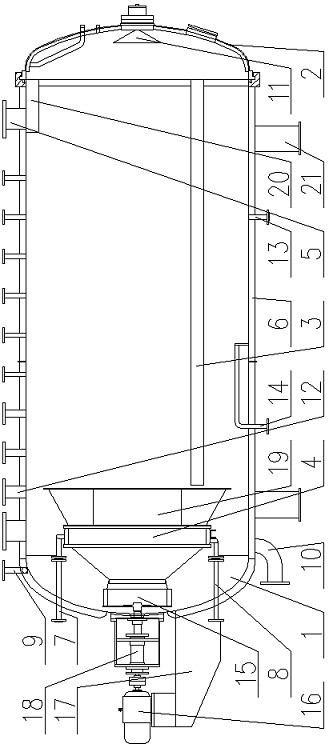

Embodiment 1

[0047] This application is used as a sterilizing kettle. When the material to be sterilized is solid or packaging material, place the material to be sterilized on the trolley; after opening the cover door 2, push the trolley into the horizontal kettle body 1 through the track 3, and Ensure that the materials to be sterilized placed on the trolley on the track 3 are within the range surrounded by the larger end of the guide tapered pipe 19; Pressurize or evacuate the horizontal kettle body 1; then heat the medium B through the medium heating device B and then flow into the kettle body heat source device 4, and then pass through the cooling fins 15 to make the kettle body heat source device 4 along The guide direction of the guide tapered tube 19 carries out heat radiation, and the fins provided on the guide tapered tube 19 and its inner wall through the heat radiation concentrate the heat in the range of the larger end of the guide tapered tube 9 inner diameter, and evenly and g...

Embodiment 2

[0049] This application is used as a sterilizing kettle. When the material to be sterilized is liquid, the liquid inlet pipe B12 with the largest inner diameter is connected to the liquid material tank to be sterilized, and the remaining pipeline connections are the same as in Example 1; Sterilize, then enter the liquid to be sterilized into the horizontal kettle body 1 through the liquid inlet pipe B2 with the largest inner diameter; and according to the process conditions of liquid material sterilization, vacuumize the horizontal kettle body 1 through the connecting pipe 5, and then Then, the medium B is heated by the medium heating device B and then flows into the heat source device 4 of the kettle body, and passes through the cooling fins 15 so that the heat source device 4 of the kettle body radiates heat along the guiding direction of the tapered pipe 19. Radiation guide tapered pipe 19 and the fins provided on its inner wall make heat concentrated in the scope of the lar...

Embodiment 3

[0051] This application is used for material fermentation. When the material to be fermented is a material in a container or is a solid material, first complete the sterilization of the inner cavity of the horizontal kettle body 1, and place the material to be fermented on the trolley; open the cover door 2 Finally, push the trolley into the horizontal kettle body 1 through the track 3, and ensure that the materials to be sterilized placed on the trolley on the track 3 are within the range surrounded by the larger end of the guide tapered tube 19; then close the cover Door 2, and according to the process conditions of material fermentation, choose whether to pressurize or evacuate the horizontal kettle body 1 through the connecting pipe 5; then heat or cool the medium B through the medium heating device B and then flow to the heat source of the kettle body In the device 4, the heat radiation blade 15 is used to make the kettle body heat source device 4 carry out heat radiation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com