Driving control method of high-frequency frequency converter

A frequency converter and high-frequency inverter technology, which is applied in the field of drive control of high-frequency frequency converters, can solve problems such as rising and inability to meet the requirements of high-frequency drives for computing capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

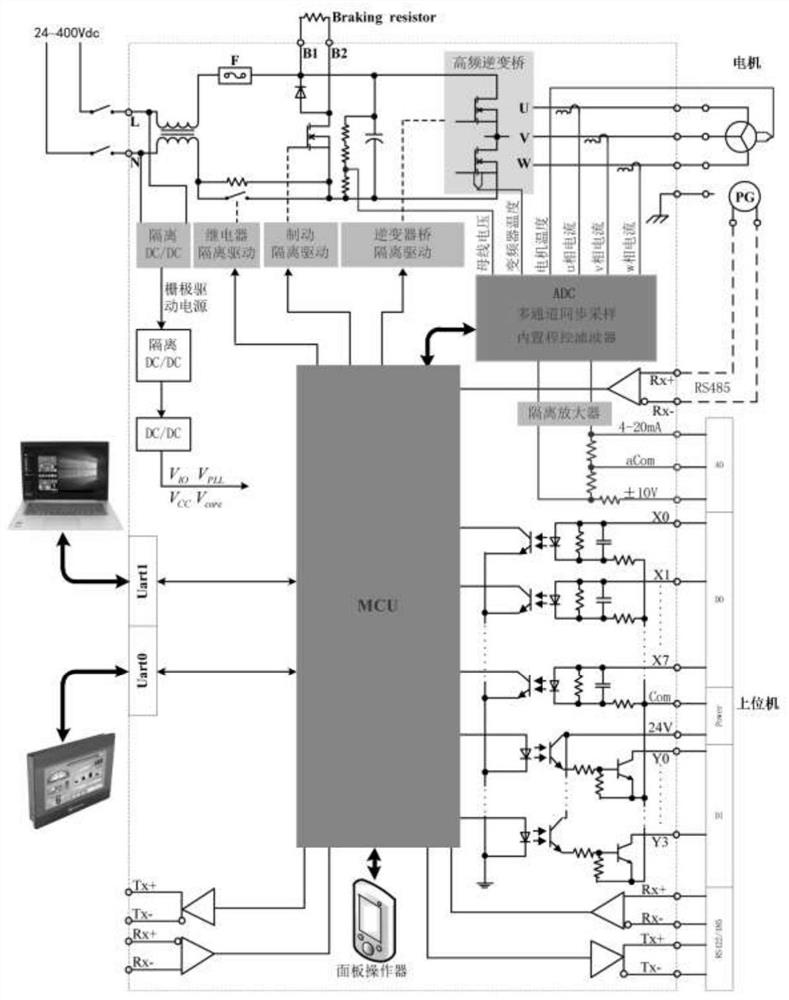

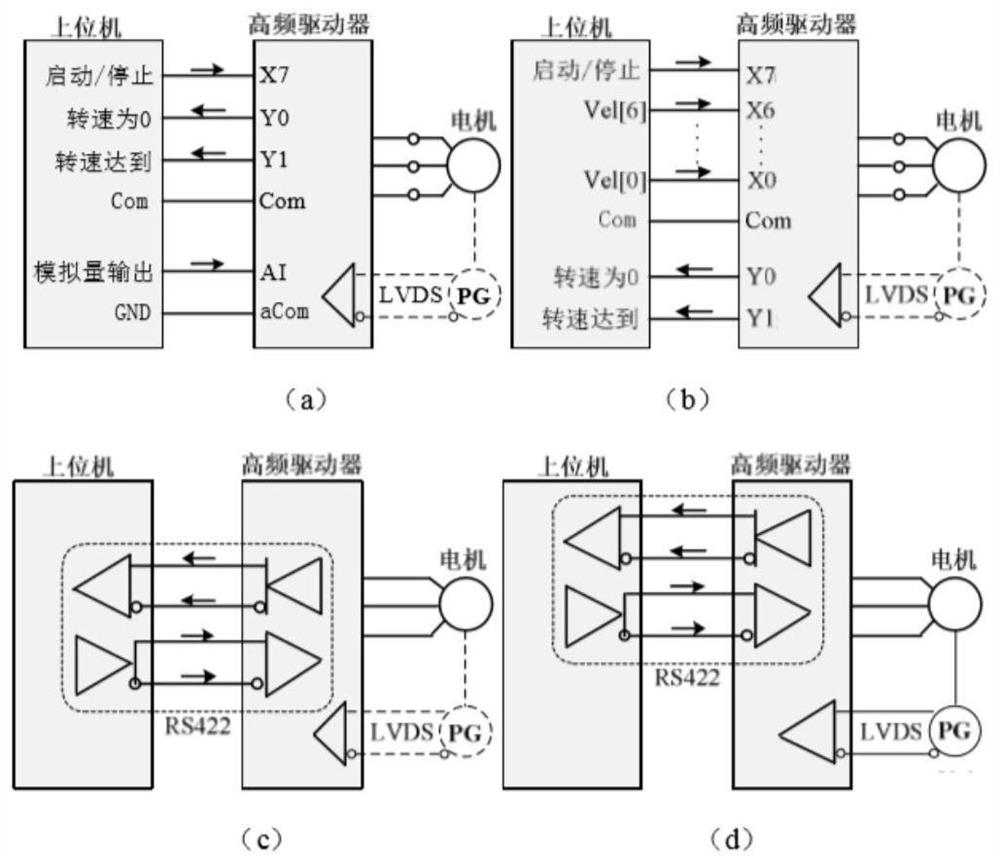

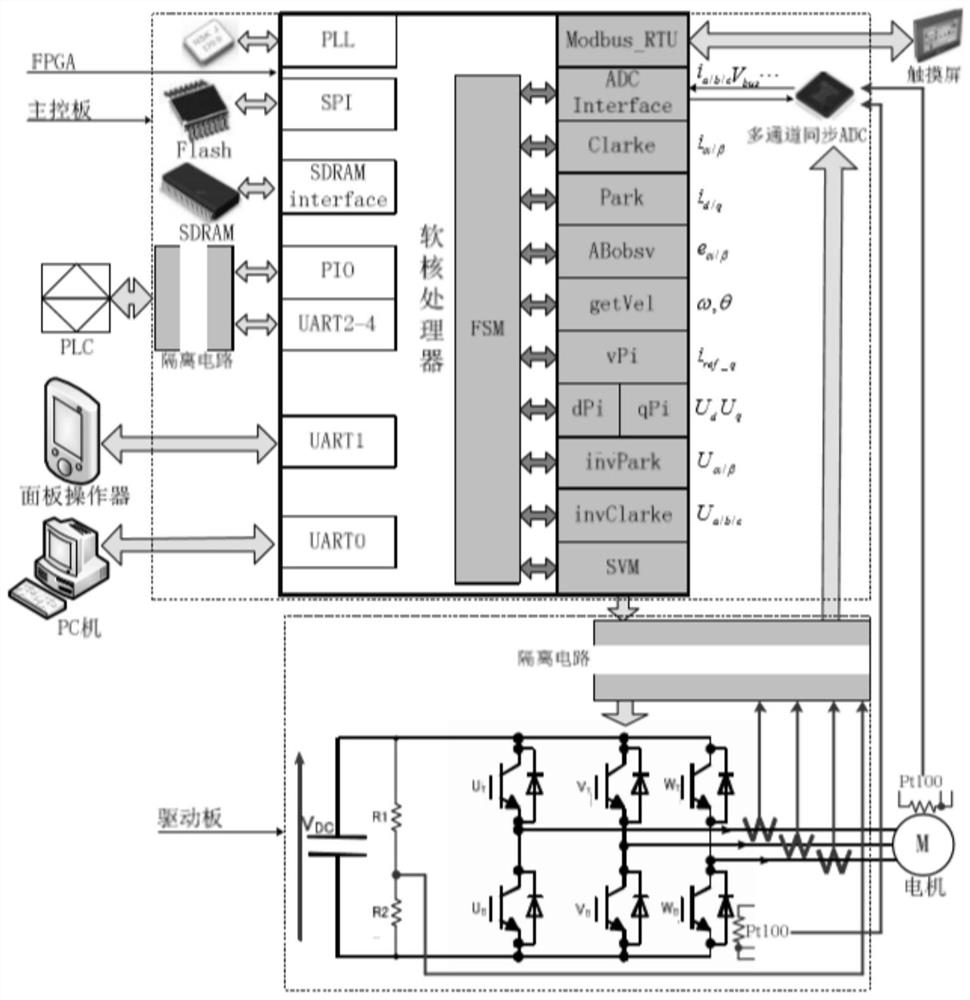

[0074] Such as figure 1 As shown, most of the high-speed motors are non-standard products. The high-frequency inverter adopts DC power input, and the input voltage range is set to 24~400Vdc. The wide range of bus voltage broadens the adaptability and application of the inverter to motors of various specifications. field. The product of the present invention belongs to the core functional components in the industrial field, and it is fully compatible with the current industrial computer, PLC and non-standard systems and other host computers. figure 1 The functions of the interface with the upper computer in the system are shown in Table 1. In the table, the RS232 interface is isolated from the strong current, and the other interfaces share the ground with the upper computer, and are completely isolated from the drive control unit circuit. The isolation voltage level is 2.1kV. The programmable communication interface can be set by the touch screen or the panel operator, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com