Automobile part bending moment strength detector

A technology for strength testing and auto parts, which is applied in the direction of strength characteristics, vehicle testing, and the use of stable bending force to test the strength of materials, etc., to achieve the effects of accurate detection results, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

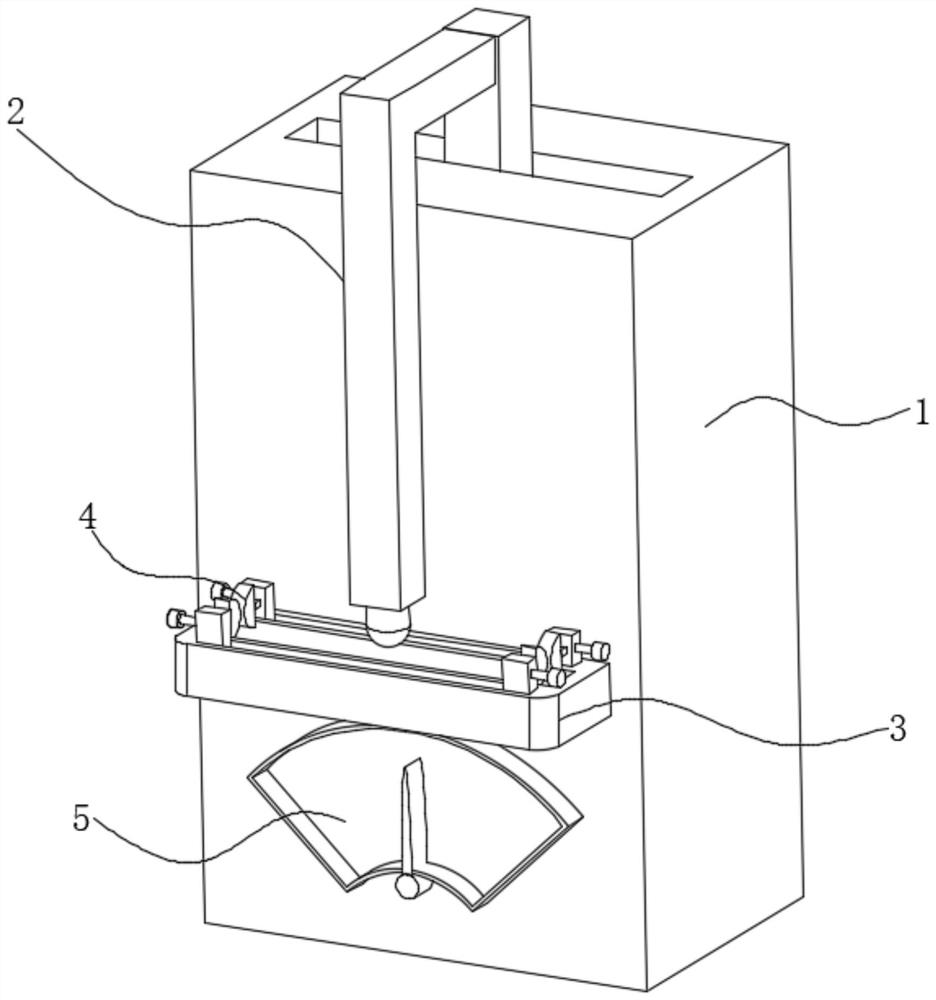

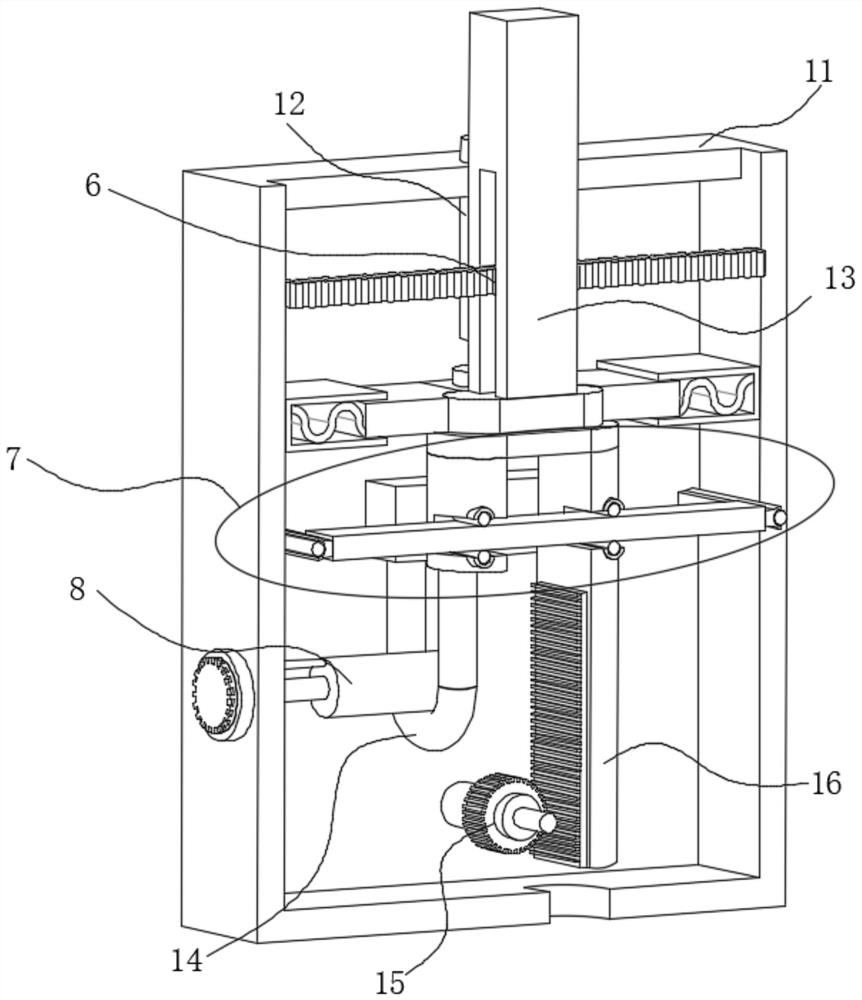

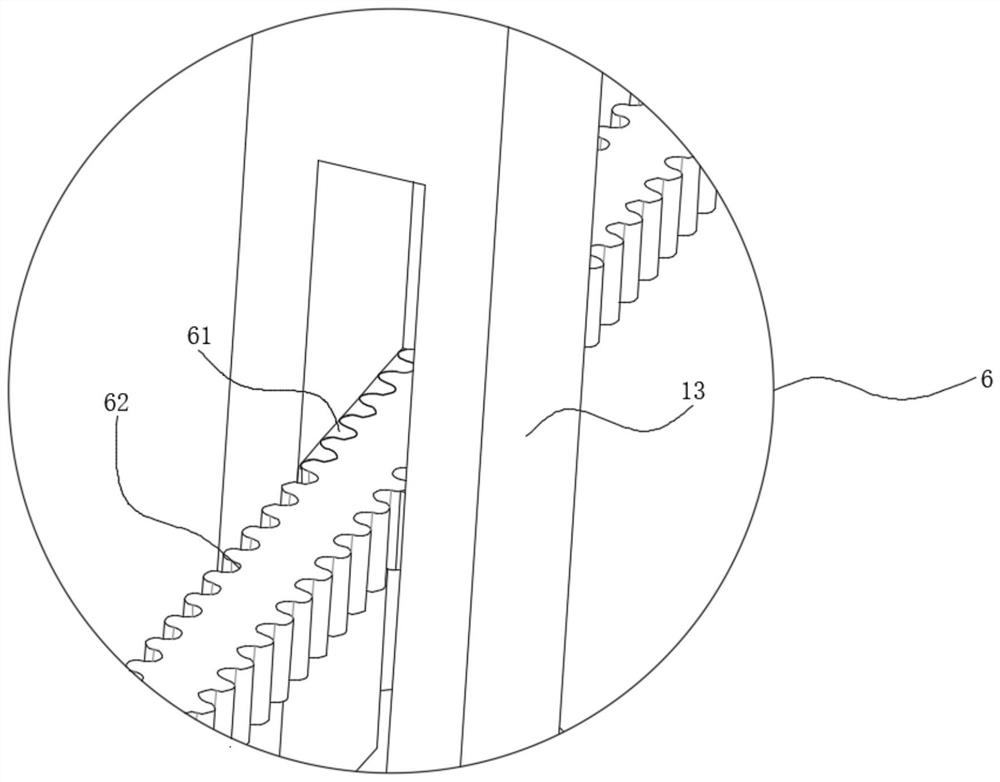

[0024] use Figure 1-Figure 6 A bending moment strength detector for auto parts according to an embodiment of the present invention is described as follows.

[0025] Such as Figure 1-Figure 6 As shown, a bending moment strength detector for auto parts according to the present invention includes a detection box 1, the top of the detection box 1 is fixedly connected with an external pressure arm 2, and the bottom end of the external surface of the external pressure arm 2 slides A stage 3 is connected, the back of the stage 3 is fixedly connected to the front of the detection box 1, the upper surface of the stage 3 is slidably connected with a buckle 4, and the bottom end of the buckle 4 The chute is slidably connected with the inner cavity of the stage 3, and a pointer indicator 5 is arranged under the carrier platform 3, and the back of the pointer indicator 5 is fixedly connected with the inner cavity of the detection box 1. When the device is in use, the user clamps the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com