Continuous grain heat pump drying system

A heat pump drying and grain technology, applied in grain drying, drying, dryer and other directions, can solve the problems of unrecycled waste heat of drying equipment, low heating efficiency and energy efficiency, and reduce system wind resistance, system The effect of small wind resistance and high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

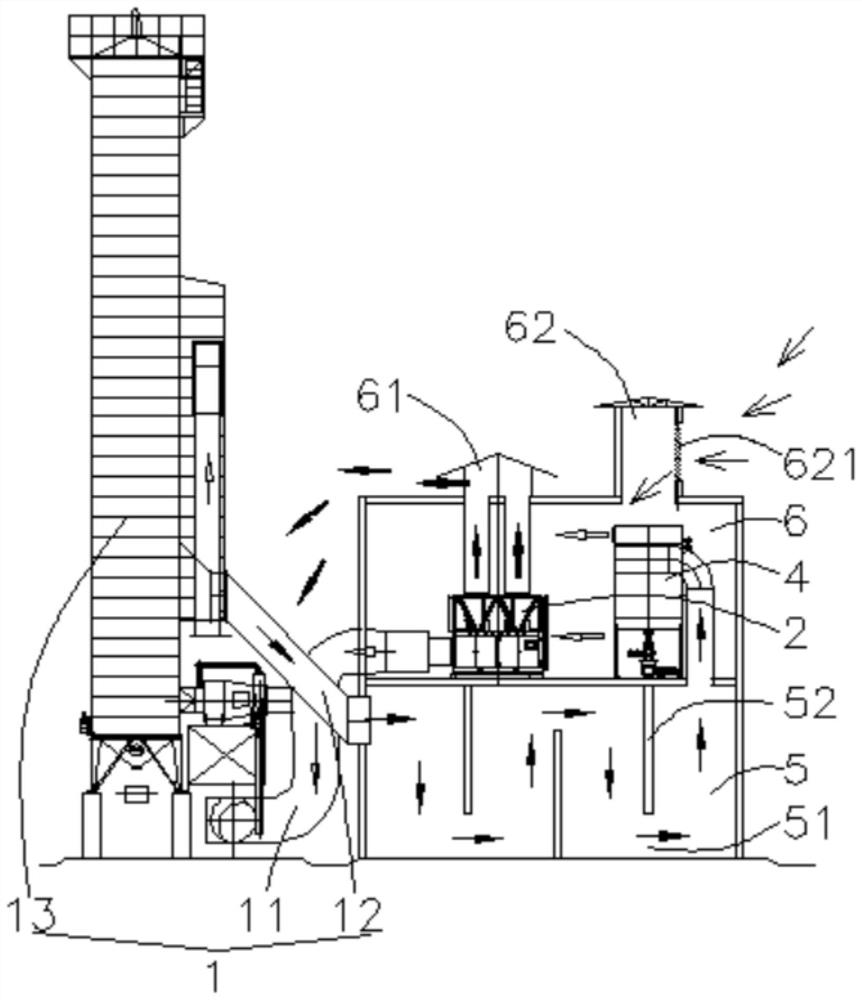

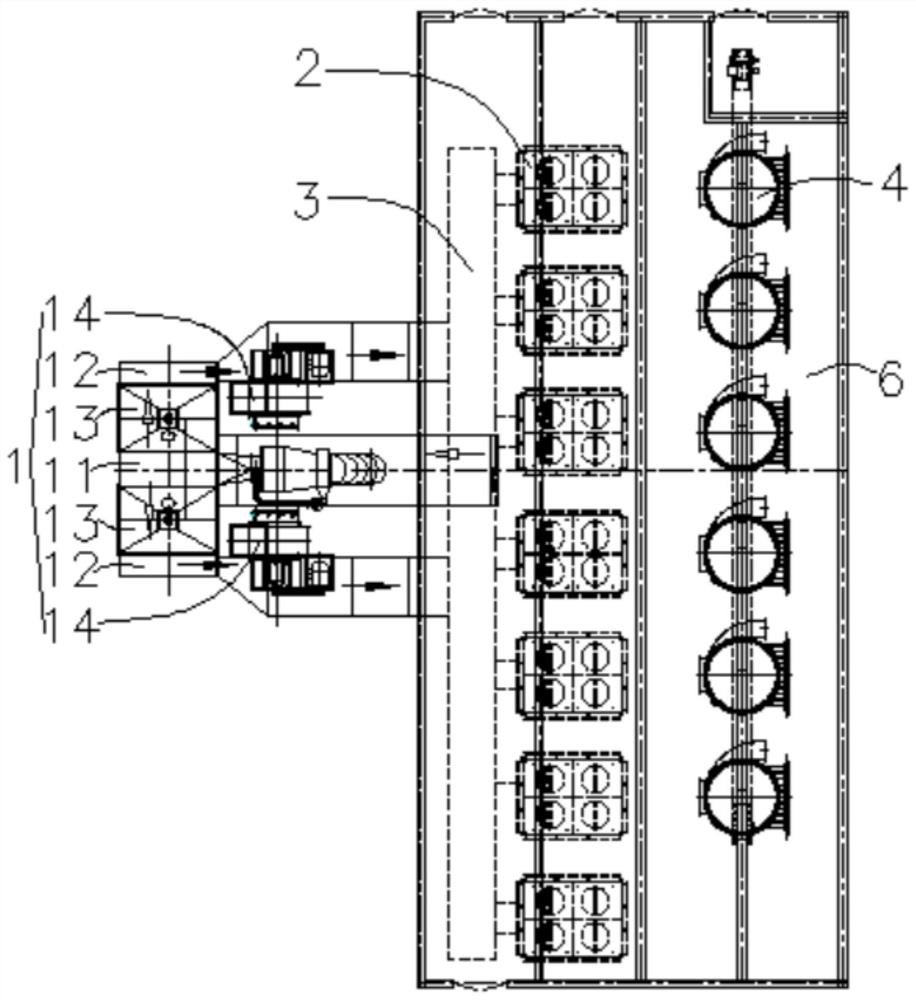

[0029] Such as figure 1 and figure 2 As shown, a continuous grain heat pump drying system includes a dryer 1, multiple air energy heat pumps 2, a total hot air pipe 3, a pulse dust collector 4, a settling chamber 5 and a hot air room 6; the hot air room 6 Set above the settling chamber 5, the air inlet of the pulse dust collector 4 communicates with the upper part of the settling chamber 5, the air outlet of the pulse dust remover 4 communicates with the hot air room 6, and the air energy heat pump 2 is arranged in the hot air room 6, the air inlet of the air energy heat pump 2 is connected to the hot air room 6, and the hot air outlets of multiple air energy heat pumps 2 are connected to the total hot air pipe 3, and the hot air outlet of the total hot air pipe 3 is connected to the oven. The hot air channel 11 of the dryer 1 is connected, and the exhaust gas channel 12 of the dryer 1 is communicated with the settling chamber 5; The air cap 61 communicates with the cold ai...

Embodiment 2

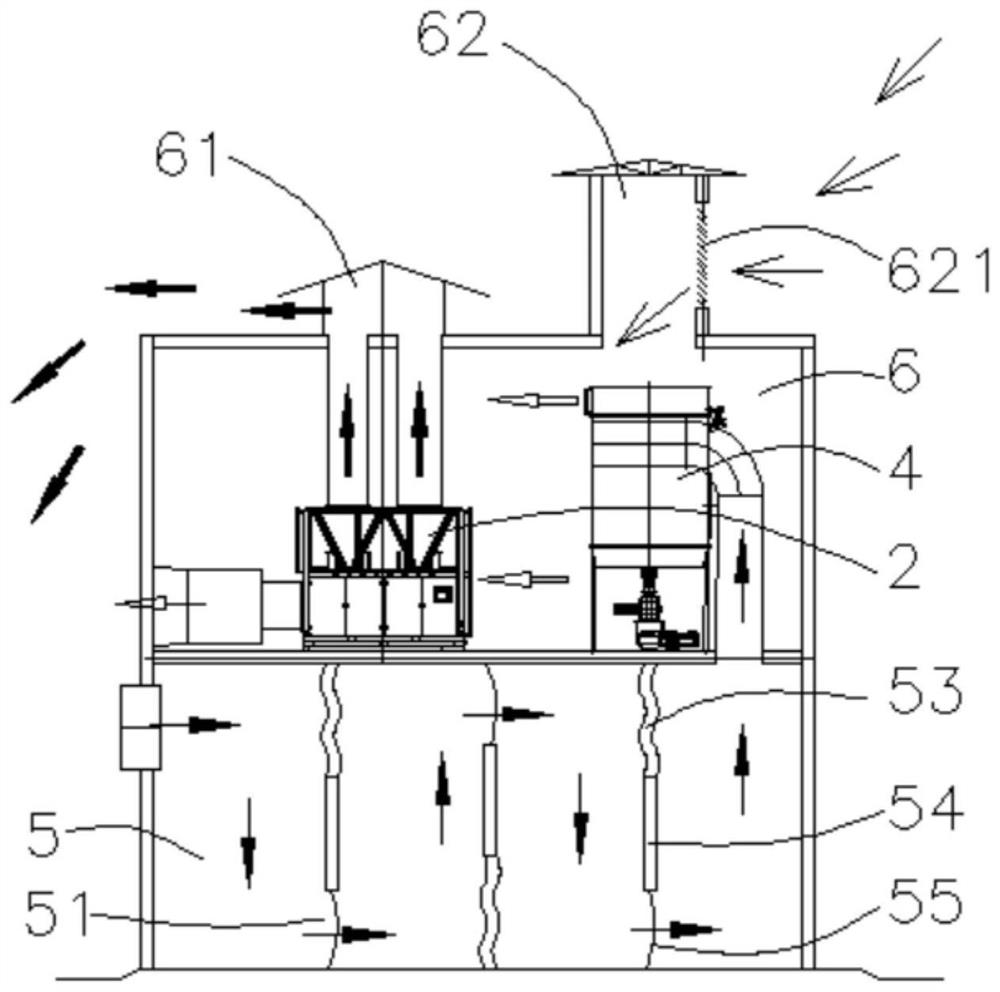

[0039] Such as image 3 As shown, in this embodiment, the difference from Embodiment 1 is that the material blocking structure includes a flexible blocking section 53 and a rigid blocking section 54 connected in sequence, and the flexible blocking section 53 is fixedly connected to the settling chamber 5, so The rigid retaining section 54 is fixedly connected to the settling chamber 5 through a rope 55, and the rope 55 is located at the corresponding airflow gap 51; the material of the flexible retaining section 53 in this embodiment is rubber, plastic, foam or non-woven fabric . The flexible retaining section 53 of this embodiment combined with the rigid retaining section 54 has a certain degree of flexibility and a certain supporting rigidity. Better impact on the material retaining structure and deceleration, and the cost of the flexible retaining section 53 is relatively low; The structure is better to reduce the dust speed, shake off the dust effectively, and further im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com