Heat pipe assembly, combined heat pipe type hot roller comprising heat pipe assembly and machining method of combined heat pipe type hot roller

A processing method, heat pipe technology, applied in the direction of stretch spinning, artificial filament heat treatment, etc., can solve the problems affecting the dynamic balance adjustment of the heat roller, the heat pipe can not be connected, and affect the heat transfer effect, etc., to achieve compact structure and low cost , high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

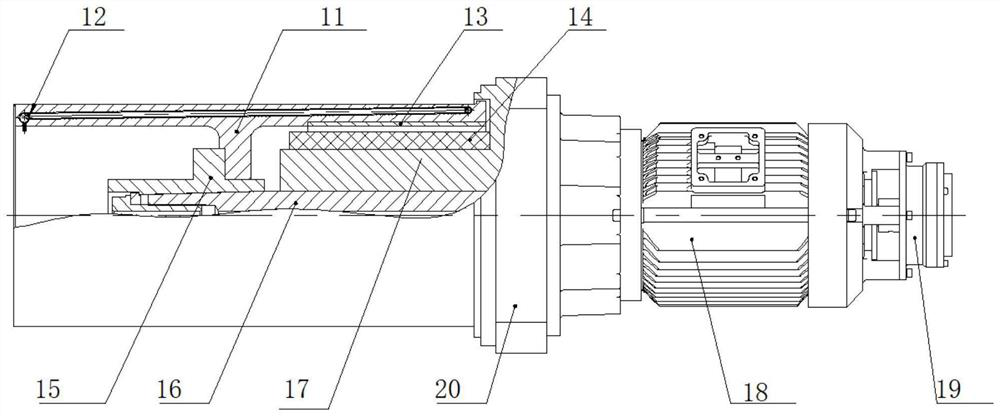

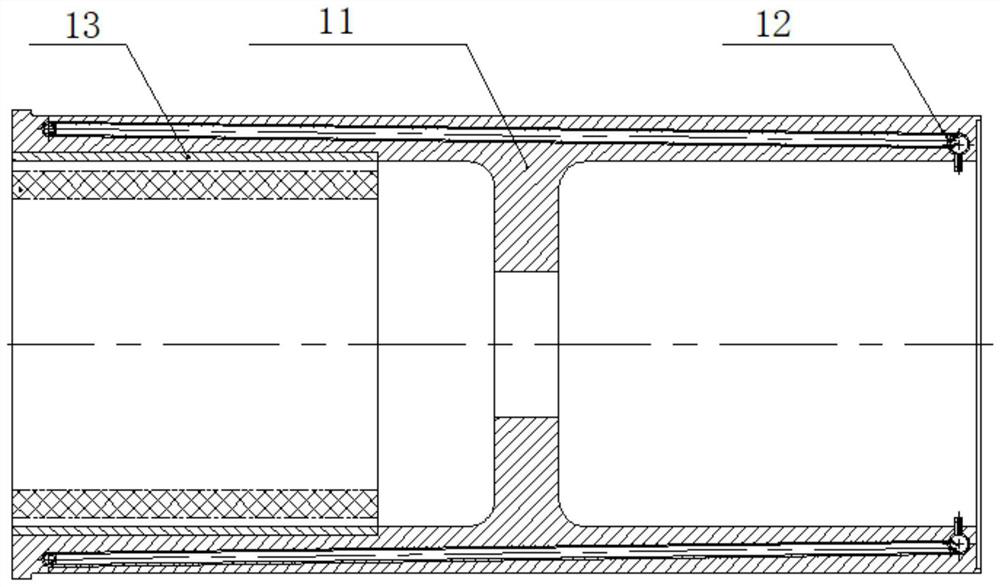

[0044] Such as Figure 1-2 A combined heat pipe type heat roll, wherein: the heat roll includes a roll body 11, a heat pipe assembly 12 and a sleeve 13 are arranged inside the roll body 11, and a connecting taper sleeve 15 is fixedly connected to the roll body 11, so A motor shaft 16 is arranged on the connecting taper sleeve 15, and the motor shaft 16 is connected to the roller body 11 through the connecting taper sleeve 15. A connecting seat 17 is arranged on the motor shaft 16, and an induction heating mechanism 14 is arranged on the connecting seat 17. One end of the connection seat 17 is connected to the shaft seat 20 , the shaft seat 20 is connected to the motor 18 , and the motor 18 is connected to the temperature transmitter 19 .

[0045] In addition to the high-speed rotation mechanism, heat supply mechanism and control mechanism in the above structure, the most important part is the structure of the heat pipe assembly, which directly affects the production and manufact...

Embodiment 2

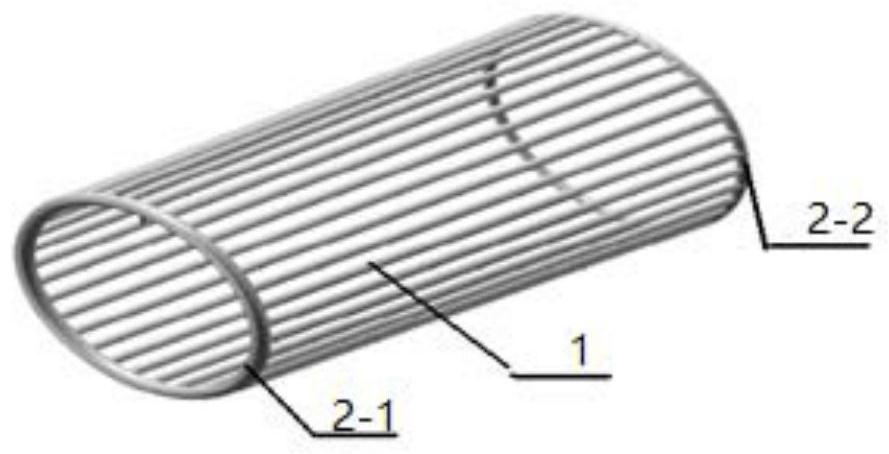

[0053] Such as Figure 3-4 As shown, a heat pipe assembly includes a combination heat pipe 1 and a heat ring 2 connected to the combination heat pipe 1. The combination heat pipe 1 includes a plurality of axially arranged heat pipes, each of which is an inclined pipe, and each of the The slope of the inclined tube is greater than 0° and less than or equal to 2.5°, one end of the combined heat pipe 1 is connected to the heat ring 2, and the other end is closed.

[0054] With the layout of the inclined tube combined heat pipe of the present invention, the length of the heating coil can be controlled according to the amount of heat medium to be 35% of the length of the roller body as the heating section, and the length of the heating coil only needs about 1 / 3 of the original heating coil. The system heats the liquid medium intensively, and quickly converts the heat generated by the electromagnetic eddy current into the latent heat of vaporization, maximizing the heat pipe effect....

Embodiment 3

[0074] Such as Figure 3-4 As shown, a heat pipe assembly includes a combination heat pipe 1 and a heat ring 2 connected to the combination heat pipe 1. The combination heat pipe 1 includes a plurality of axially arranged heat pipes, each of which is an inclined pipe, and each of the The slope of the inclined tube is greater than 0° and less than or equal to 2.5°, and both ends of the combined heat pipe 1 communicate with the heat ring 2; the heat ring 2 includes 2-1 and 2-2.

[0075] With the layout of the inclined tube combined heat pipe of the present invention, the length of the heating coil can be controlled according to the amount of heat medium to be 40% of the length of the roller body as the heating section, and the length of the heating coil only needs about 1 / 3 of the original power frequency coil. The ferritic steel sleeve on the inner surface of the aluminum alloy roller body transfers heat to the aluminum alloy roller body and the heat medium liquid in the combin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com