Strong oxidant cleaning solution for wafer boat for semiconductor production and cleaning method thereof

A strong oxidizing agent and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, inorganic non-surface-active cleaning compositions, electrical components, etc., can solve the problem of incomplete removal of pollutants, and achieve clean surfaces, low cost, and no corrosion marks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

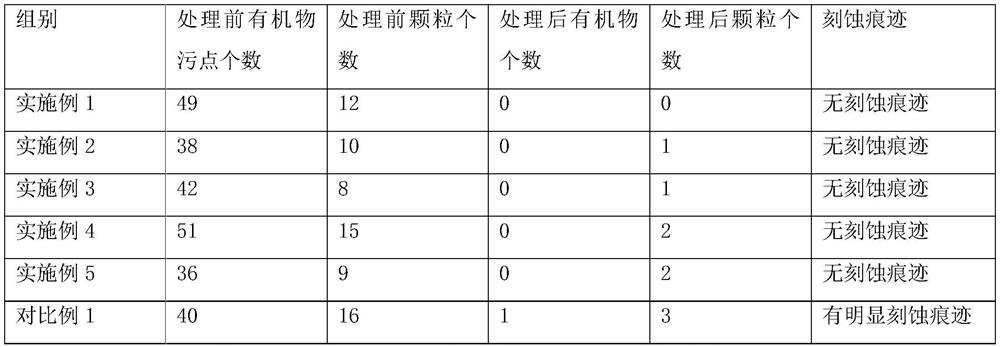

Examples

Embodiment 1

[0021] A method for cleaning a crystal boat used in semiconductor production, comprising the steps of:

[0022] The first step is to soak the crystal boat to be cleaned in a hydrofluoric acid solution with a concentration of 2% for 10 minutes;

[0023] The second step is to soak the crystal boat in a mixed solution of 5% hydrofluoric acid and 3% potassium permanganate for 30 minutes;

[0024] There is a nitrogen bubbling device at the bottom of the immersion tank used, and the nitrogen flow rate is 50L / H;

[0025] The third step is to use ultrapure water to overflow the crystal boat for 5H;

[0026] The fourth step is to soak the crystal boat in 5% hydrogen peroxide for 1H, and the temperature of the hydrogen peroxide is 50°C;

[0027] There is a nitrogen bubbling device at the bottom of the soaking tank used, and the nitrogen flow rate is 30L / H;

[0028] The fifth step is to use ultrapure water to overflow the crystal boat for 5 hours;

[0029] The sixth step is to take o...

Embodiment 2

[0032] A method for cleaning a crystal boat used in semiconductor production, comprising the steps of:

[0033] The first step is to soak the crystal boat to be cleaned in a hydrofluoric acid solution with a concentration of 2% for 20 minutes;

[0034] The second step is to soak the crystal boat in a mixed solution of 5% hydrofluoric acid and 1% potassium dichromate for 30 minutes;

[0035] There is a nitrogen bubbling device at the bottom of the immersion tank used, and the nitrogen flow rate is 40L / H;

[0036] The third step uses ultrapure water to overflow the crystal boat for 3H;

[0037] The fourth step is to soak the crystal boat in 5% hydrogen peroxide for 1H, and the temperature of the hydrogen peroxide is 40°C;

[0038] There is a nitrogen bubbling device at the bottom of the immersion tank used, and the nitrogen flow rate is 40L / H;

[0039] The fifth step is to use ultrapure water to overflow the crystal boat for 5 hours;

[0040] The sixth step is to take out th...

Embodiment 3

[0043] A method for cleaning a crystal boat used in semiconductor production, comprising the steps of:

[0044] The first step is to soak the crystal boat to be cleaned in a hydrofluoric acid solution with a concentration of 2% for 16 minutes;

[0045] The second step is to soak the crystal boat in a mixed solution of 10% hydrofluoric acid and 5% potassium permanganate for 8 minutes;

[0046] There is a nitrogen bubbling device at the bottom of the soaking tank used, and the nitrogen flow rate is 45L / H;

[0047] The third step is to use ultrapure water to overflow the crystal boat for 8 hours;

[0048] The fourth step is to soak the crystal boat in 6% hydrogen peroxide for 1H, and the temperature of the hydrogen peroxide is 60°C;

[0049] There is a nitrogen bubbling device at the bottom of the immersion tank used, and the nitrogen flow rate is 25L / H;

[0050] The fifth step is to use ultrapure water to overflow the crystal boat for 6 hours;

[0051] The sixth step is to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com