Preparation method of ultra-thin glass, ultra-thin glass and application thereof

A technology of ultra-thin glass and glass frit, which is applied in glass manufacturing equipment, glass forming, glass tempering, etc. It can solve problems such as bending and deformation, achieve high compressive strength, improve yield rate, and improve thinning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The first aspect of the present invention provides a method for preparing ultra-thin glass, the method comprising:

[0022] (1) Thinning the glass frit twice to obtain an ultra-thin glass frit;

[0023] (2) In the presence of a binder, paste the ultra-thin glass frit on one or both sides of the support to obtain the first composite glass sample;

[0024] (3) chemically thinning the first composite glass sample to obtain a second composite glass sample;

[0025] (4) removing the support member and the cured binder in the second composite glass sample, and then performing finishing to obtain the ultra-thin glass initial product;

[0026] (5) Tempering the ultra-thin glass primary product to obtain ultra-thin glass.

[0027] In the present invention, the inventors use a specific support with excellent acid corrosion resistance to bond the ultra-thin glass frit obtained after secondary thinning, and carry out the single-layer or double-layer ultra-thin glass frit with the...

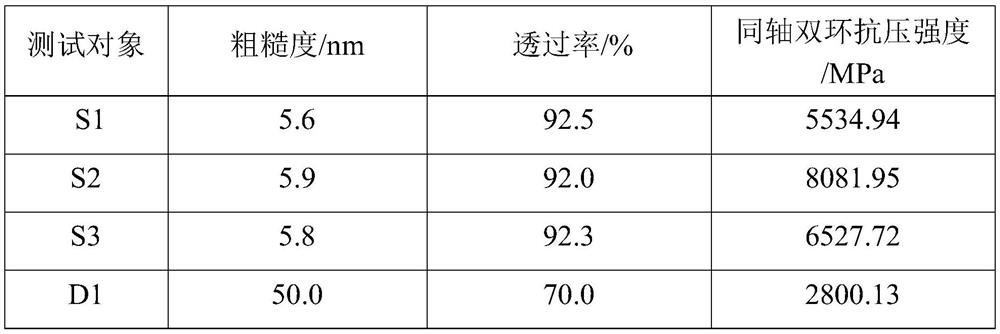

Embodiment 1

[0054] (1) Perform secondary thinning of ordinary glass to obtain ultra-thin glass frit with a thickness of 0.3mm, and conduct quality inspection on ultra-thin glass frit to screen out products with defects such as uneven thickness, dirt, and nodules, Clean the qualified products after screening;

[0055] (2) Teflon sheets with a thickness of 0.5 mm are used as support members, and rosin resin is used as a binder. Cut the length and width of the PTFE sheet to be consistent with the length and width of the above-mentioned ultra-thin frit. Use the manipulator to place the trimmed PTFE sheet on the operating frame, use the glue applicator to evenly coat the rosin resin on one side of the PTFE sheet (the coating thickness is 20 μm), and use the manipulator to coat a piece of ultra-thin glass The material is bonded to this surface, and then the whole is turned over, and the other side of the polytetrafluoroethylene sheet is also uniformly coated with rosin resin (the coating thick...

Embodiment 2

[0060] (1) Perform secondary thinning of ordinary glass to obtain ultra-thin glass frit with a thickness of 0.1mm, and conduct quality inspection on ultra-thin glass frit to screen out products with defects such as uneven thickness, dirt, and nodules, Clean the qualified products after screening;

[0061] (2) The supporting member is a polyvinyl chloride sheet with a thickness of 0.3mm, and methyl silicone oil is used as a binder. The length and width of the polyvinyl chloride sheet were cut to be consistent with the length and width of the above-mentioned ultra-thin frit. Use the manipulator to place the cut polyvinyl chloride sheet on the operating frame, use a glue applicator to evenly coat one side of the polyvinyl chloride sheet with methyl silicone oil (the coating thickness is 5 μm), and use the manipulator to spread a piece of ultra-thin glass frit Laminate with this surface, then turn the whole over, evenly coat the other side of the polyvinyl chloride sheet with met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com