Multi-layer overhead closed conveying gallery steel pipe truss combination system

A combined system, steel pipe truss technology, applied in the direction of conveyors, conveyor objects, supporting frames, etc., can solve problems such as unfavorable construction and structural corrosion protection and protection, low utilization rate of structures or structural components, unfavorable structural corrosion protection and later protection, etc. , to simplify the node connection structure, reduce the production workload, and improve the production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

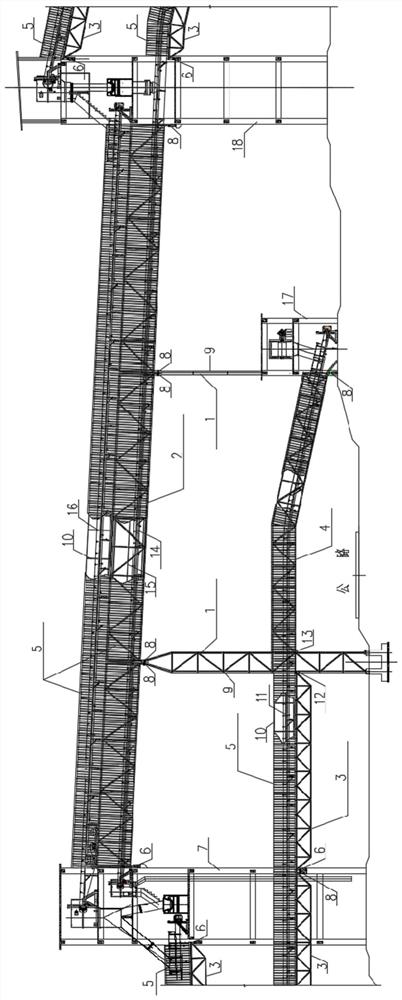

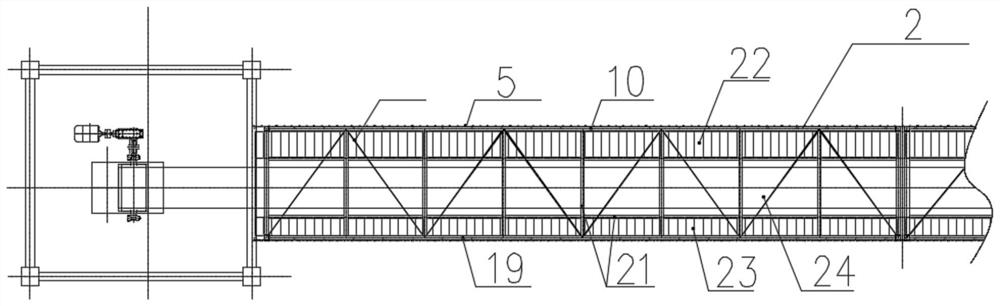

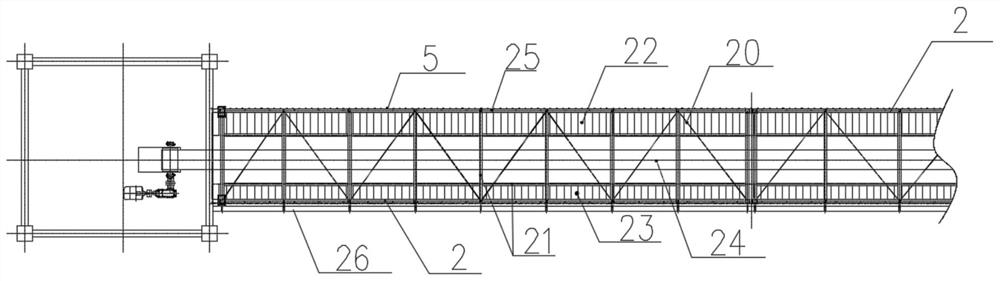

[0052] In this embodiment, a steel pipe truss combination system for multi-storey overhead closed conveying corridors is specifically provided. The main improvement point of the combined system is that by planning the process flow and running direction of material transportation, it is improved to carry out multiple belts on a plane. In the way of independent arrangement of single conveyor, multiple belt conveyors running in the same direction are arranged on different heights of the same facade (same vertical plane), and a three-dimensional overall structure of spatial arrangement is formed through three-dimensional arrangement.

[0053] like Figure 1-Figure 6 As shown, the combined system is mainly divided into three parts, which are: the transfer station, the conveying corridor and the column support 1, wherein, in the layout of the transfer station, the position and running direction of the materials entering and leaving the workshop are optimized, so that In the intermed...

Embodiment 2

[0084] In Embodiment 1, the specific structural composition of the steel pipe truss combination system of the multi-layer overhead closed conveying corridor is provided. In this embodiment, the corresponding construction method in actual application is provided. The construction method is as follows:

[0085] S1: Design stage

[0086] S101: Carry out the structural layout of the conveying corridor according to the design data and site conditions, and determine the type and layout position of the trusses and supports of the conveying corridor.

[0087] S102: Using finite element design software, establish the overall calculation model of the conveying corridor, and carry out structural finite element design analysis and calculation. In particular, it should be noted that the multi-storey corridor is a relatively complex structure, and it is necessary to consider the unfavorable live load arrangement of the multi-storey corridor, the transverse wind vibration generated by the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com