Micro-nano layer-shaped copper/copper alloy composite board and preparation method thereof

A composite plate and copper alloy technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of low material utilization rate, limited strength improvement, insufficient interface bonding strength, etc., to achieve the number of plate layers and Controllable thickness, improved smoothness and flatness, and high raw material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment adopts the following equipment: thermal diffusion welding equipment, forging equipment, and four-roll rolling mill.

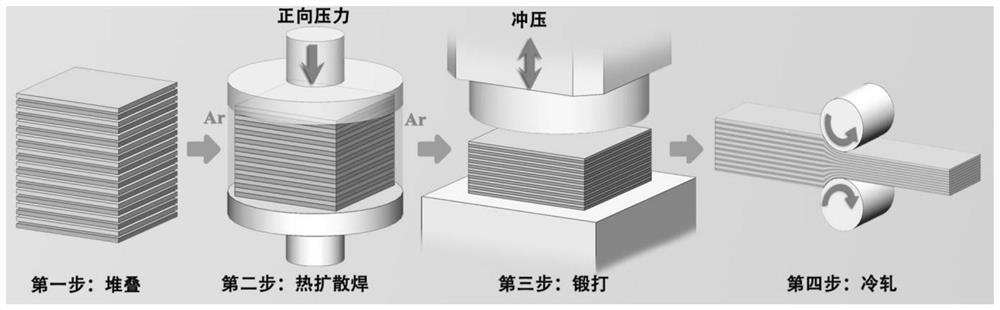

[0044] The process flow chart of the preparation method for preparing a micro-nano layered copper / copper alloy composite board in this embodiment is as follows figure 1 As shown, the specific operation is as follows:

[0045] 1) The copper and copper alloy used in this embodiment are T2 pure copper and H70 brass respectively, the thickness of the T2 pure copper plate is 1mm, the thickness of the H70 brass plate is 0.8mm, and the plane size is 80×100mm 2 , the chemical composition (mass percentage) of the T2 pure copper plate used is: Cu+Ag: 99.94%, Zn: 0.0041%, Pb: 0.0007%, Sn: 0.0005%, Fe: 0.0031%, Ni: 0.0028% , Si: 0.028%, and the rest are unavoidable impurities; the chemical composition (mass percentage) of H70 brass plate is: Cu: 70.12%, Zn: 29.7%, Fe: 0.035%, Pb: 0.001%, Sb: 0.001%, Bi: 0.0006%, Ni: 0.08%, and the rest are unavoida...

Embodiment 2

[0051] This embodiment adopts the following equipment: thermal diffusion welding equipment, forging equipment, and four-roll rolling mill.

[0052] The process flow chart of the preparation method for preparing a micro-nano layered copper / copper alloy composite plate / foil in this example is as follows figure 1 As shown, the specific operation is as follows:

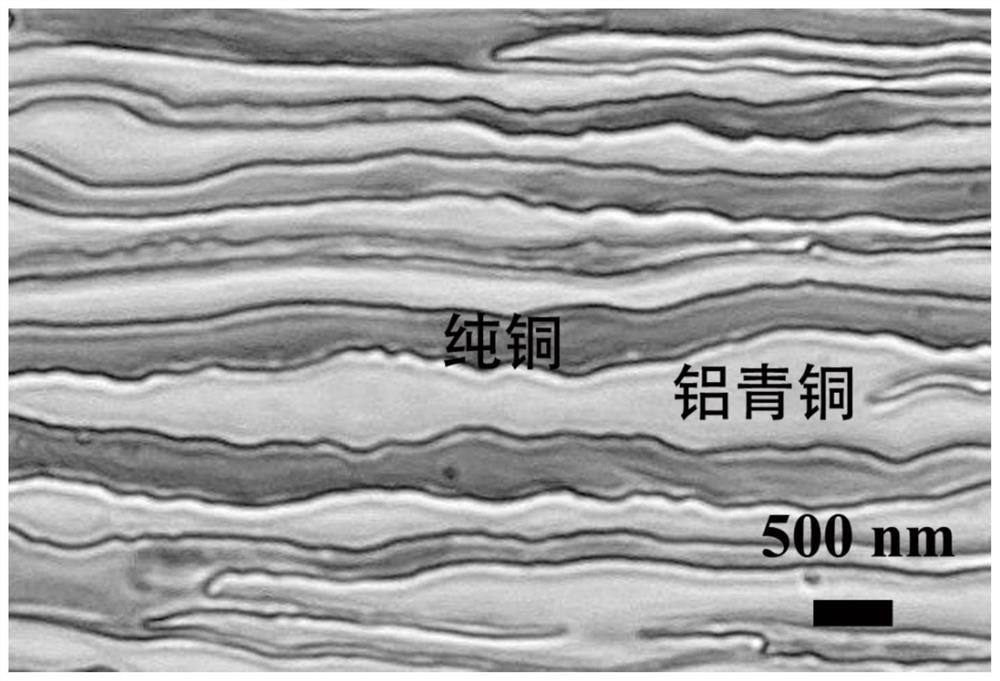

[0053] 1) The thickness of the T2 pure copper used in this embodiment is 0.5mm, the thickness of the QAl-10-3-1.5 aluminum bronze plate is 0.5mm, and the plane size is 100×100mm 2 , the chemical composition (mass percentage) of pure copper used is: Cu+Ag: 99.94%, Zn: 0.0041%, Pb: 0.0007%, Sn: 0.0005%, Fe: 0.0031%, Ni: 0.0028%, Si : 0.028%, the rest are unavoidable impurities; the chemical composition (mass percentage) of QAl-10-3-1.5 aluminum bronze is: Cu: 84.12%, Al: 9.67%, Mn: 1.52%, Zn: 0.50% , Fe: 3.21%, Pb: 0.03%, Ni: 0.51%, and the rest are unavoidable impurities.

[0054] 2) Select 100 pieces of T2 pure copper ...

Embodiment 3

[0059] This embodiment adopts the following equipment: thermal diffusion welding equipment, forging equipment, and four-roll rolling mill.

[0060] The process flow chart of the preparation method for preparing a micro-nano layered copper / copper alloy composite plate / foil in this example is as follows figure 1 As shown, the specific operation is as follows:

[0061] 1) The thickness of the T2 pure copper used in this embodiment is 1 mm, the thickness of the copper chromium zirconium plate is 1 mm, and the plane size is 50 × 50 mm 2 , the chemical composition (mass percentage) of pure copper used is: Cu+Ag: 99.94%, Zn: 0.0041%, Pb: 0.0007%, Sn: 0.0005%, Fe: 0.0031%, Ni: 0.0028%, Si : 0.028%, the rest are unavoidable impurities; the chemical composition (mass percentage) of copper chromium zirconium is: Cu: 96.90%, Al: 0.23%, Mg: 0.184%, Cr: 0.57%, Zr: 0.50%, Fe: 0.49%, Si: 0.51%, P: 0.11%, and the rest are unavoidable impurities.

[0062] 2) Select 10 pieces of T2 pure coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com