Efficient extraction method of inonotus obliquus total triterpenes and preparation method of fine powder of inonotus obliquus total triterpenes

A technology of Inonotus obliquus and its extraction method, which is applied in the field of high-efficiency extraction method and its fine powder preparation, can solve the problems of poor biological activity of the product, large solvent demand, and many uncontrollable factors, and achieve good market promotion prospects, The effect of reducing the extraction time and reducing the amount of ethanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

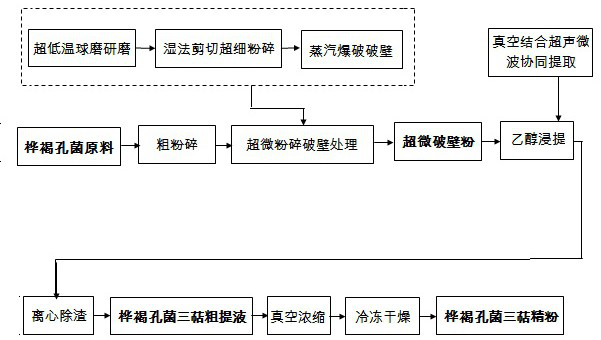

[0039] The extraction rate of total triterpenes of Inonotus obliquus prepared by the extraction method of total triterpenes of Inonotus obliquus is 3.4%, and the scavenging rate of DPPH free radical is 93.20%. Such as figure 1 As shown, the extraction method of Inonotus obliquus fine powder is as follows:

[0040] Step 1. The raw material of Inonotus obliquus is pulverized by a universal pulverizer, and passed through a 60-mesh sieve to obtain Inonotus obliquus coarse powder.

[0041] Step 2: Grinding the Inonotus obliquus coarse powder in Step 1 with a ball mill in a liquid nitrogen low temperature environment to obtain Inonotus obliquus micropowder. The grinding conditions are: grinding time 1h, material-ball ratio 1:1, rotating speed 300r / min, particle size of fine powder after grinding is 28-30μm.

[0042] Step 3. Add deionized water to the Inonotus obliquus micropowder obtained in step 2 according to 1g:10mL, and configure it into a suspension.

[0043] Step 4: The su...

Embodiment 2

[0050] The extraction rate of the total triterpenes of Inonotus obliquus prepared by the extraction method of the total triterpenes of Inonotus obliquus is 4.2%, and the DPPH free radical scavenging rate is 92.60%. The extraction method of Inonotus obliquus fine powder is as follows:

[0051] Step 1. The raw material of Inonotus obliquus is pulverized by a universal pulverizer, and passed through a 70-mesh sieve to obtain Inonotus obliquus coarse powder.

[0052] Step 2: Grinding the Inonotus obliquus coarse powder in Step 1 with a ball mill in a liquid nitrogen low temperature environment to obtain Inonotus obliquus micropowder. The grinding conditions are as follows: grinding time 2h, material-to-ball ratio 1:2, rotating speed 400r / min, and the particle size of the fine powder after grinding is 18-22μm.

[0053] Step 3: add deionized water to the Inonotus obliquus micropowder obtained in step 2 according to 1g:15mL, and configure it into a suspension.

[0054] Step 4: The s...

Embodiment 3

[0061] The extraction rate of the total triterpenoids of Inonotus obliquus prepared by the extraction method of the total triterpenoids of Inonotus obliquus is 4.8%, and the DPPH free radical scavenging rate is 91.52%. The extraction method of Inonotus obliquus fine powder is as follows:

[0062] Step 1. The raw material of Inonotus obliquus is pulverized by a universal pulverizer, and passed through an 80-mesh sieve to obtain Inonotus obliquus coarse powder.

[0063] Step 2: Grinding the Inonotus obliquus coarse powder in Step 1 with a ball mill in a liquid nitrogen low temperature environment to obtain Inonotus obliquus micropowder. The grinding conditions are: grinding time 4h, material-ball ratio 1:3, rotating speed 500r / min, particle size of fine powder after grinding is 10-12μm.

[0064] Step 3. Add deionized water to the Inonotus obliquus micropowder obtained in step 2 according to 1g:20mL, and configure it into a suspension.

[0065] Step 4. The suspension of Inonotus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com