A kind of preparation method of fuel cell membrane electrode

A fuel cell membrane and membrane electrode technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of large transmission resistance proton-conducting polymers, overfilling proton exchange membranes, etc., to improve interlayer contact and interface bonding force , reduce manufacturing defects, and reduce the effect of gas barrier ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

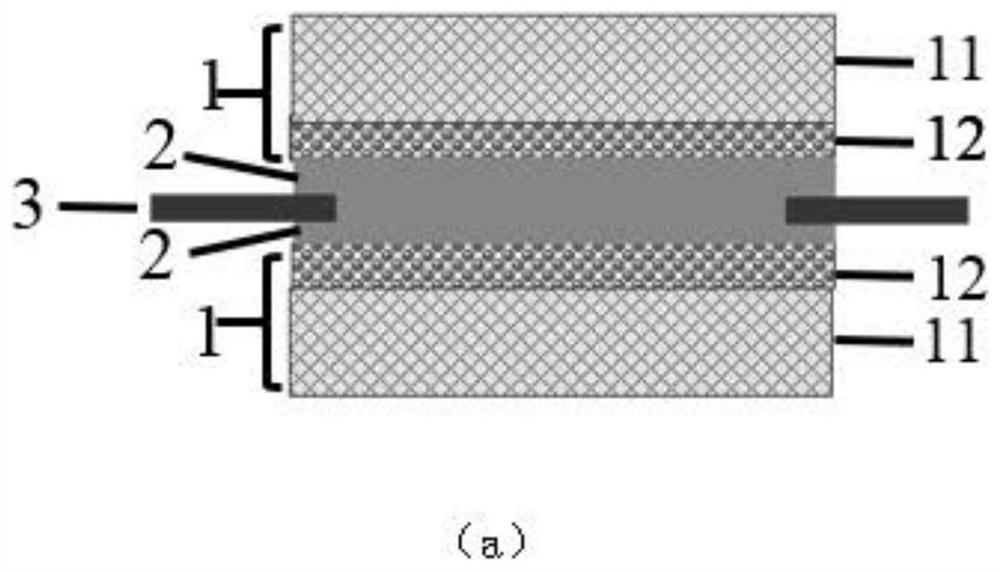

[0043] The present embodiment relates to a method for preparing a membrane electrode of a fuel cell. The membrane electrode structure is as follows: figure 2 As shown, from bottom to top, it includes a gas diffusion electrode 1, a proton exchange membrane layer 2, an insulating gas-tight frame layer 3, a proton exchange membrane layer 2 and a gas diffusion electrode 1; the gas diffusion electrode 1 includes a gas diffusion layer 11 and a catalytic layer. 12; the proton exchange membrane layer 2 is located on the catalytic layer 12 side of the gas diffusion electrode 1.

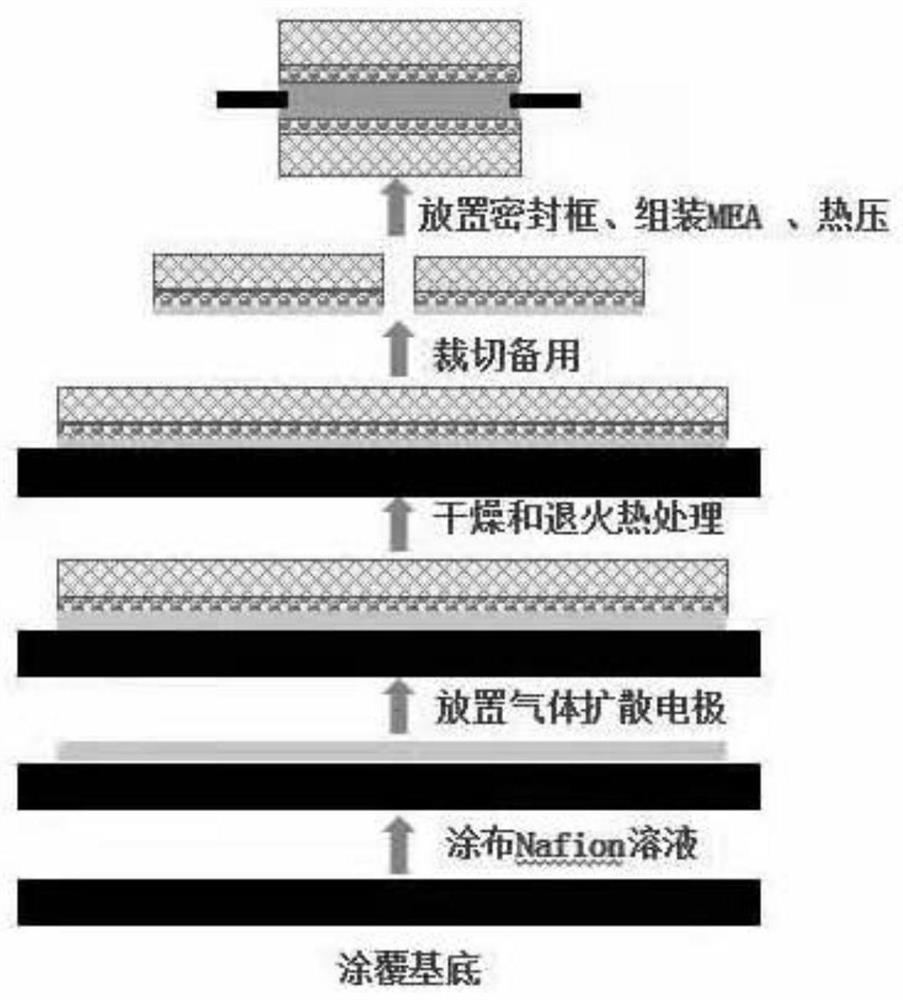

[0044] The process flow of the membrane electrode in this embodiment is as follows figure 1 shown, including the following steps:

[0045] a) Coat the 20wt% Nafion solution evenly on the PTFE substrate using a doctor blade coating device, and the coating size of the Nafion solution in this example is 10cm*30cm;

[0046] b) Preparation of membrane-coated electrode: A gas diffusion electrode with the same size ...

Embodiment 2

[0051] The process flow of the membrane electrode in this embodiment is as follows figure 1 As shown, it specifically includes the following steps;

[0052] a) uniformly coat the 20wt% Nafion solution on the glass substrate using a slit extrusion coating equipment, and the coating size of the Nafion solution in this embodiment is 10cm*30cm;

[0053] b) Preparation of membrane-coated electrode: A gas diffusion electrode with the same size as the 20 wt% Nafion solution coating is placed on the proton-conducting polymer solution coated in step a), wherein the catalytic layer side of the gas diffusion electrode is connected to the proton-conducting polymer solution. The conductive polymer solution was contacted; then the prepared samples were placed in an oven at 80°C to dry for 4 hours, and then annealed and heat-treated at 120°C for 60 minutes, and then peeled off from the glass substrate to obtain a membrane-coated electrode;

[0054] c) Cutting for standby: the large-size mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com