Transfer and adsorption method for radioactive elements in tailings in high-cold and high-altitude areas

A radioactive element, high-altitude technology, applied in radioactive purification, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problem of low transfer rate of radioactive element thorium, and achieve easy control and increase of component concentration Adsorption performance, avoiding the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

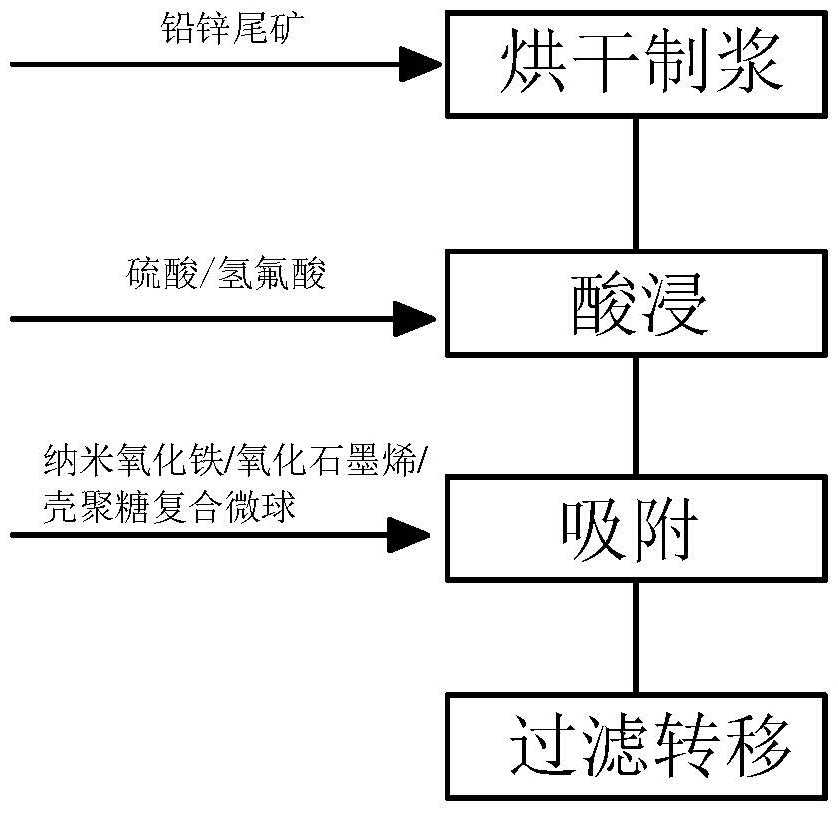

[0037] A method for transferring and adsorbing radioactive elements in tailings in high-cold and high-altitude areas, comprising the following steps:

[0038] (S.1) It was selected from a certain lead-zinc tailings in Tibet. Due to the influence of the high cold and high altitude in Tibet, the tailings containing radioactive thorium should be heated and dried in an oven at 100°C for 12 hours, and then the tailings Grinding to a tailings material with a particle size of less than 0.45 mm, and then adding water to prepare a tailings slurry with a concentration of 60 wt%.

[0039] (S.2) Immerse the tailings slurry into the hydrofluoric acid-sulfuric acid system, the volume ratio of hydrofluoric acid to sulfuric acid in the hydrofluoric acid-sulfuric acid system is 1:1, and the mass of tailings slurry to the volume of hydrofluoric acid The ratio is 1 g: 4ml, and the pH value is controlled at 3, the leaching time is 2h, and the leaching temperature is 70°C, so that the radioactive ...

Embodiment 2

[0045] A method for transferring and adsorbing radioactive elements in tailings in high-cold and high-altitude areas, comprising the following steps:

[0046] (S.1) It was selected from a lead-zinc tailings mine in Tibet. Due to the influence of the high cold and high altitude in Tibet, the tailings containing the radioactive element thorium should be heated and dried in an oven at 105°C for 24 hours, and then the tailings should be ground. Tailings material with a particle size of less than 0.45mm, and then add water to prepare tailings slurry with a concentration of 70 wt%.

[0047] (S.2) Immerse the tailings slurry into the hydrofluoric acid-sulfuric acid system, the volume ratio of hydrofluoric acid to sulfuric acid in the hydrofluoric acid-sulfuric acid system is 1:10, and the mass of tailings slurry to the volume of hydrofluoric acid The ratio is 1 g: 15ml, and the pH value is controlled at 5, the leaching time is 4h, and the leaching temperature is 90°C, so that the rad...

Embodiment 3

[0053] A method for transferring and adsorbing radioactive elements in tailings in high-cold and high-altitude areas, comprising the following steps:

[0054] (S.1) It was selected from a lead-zinc tailings mine in Tibet. Due to the influence of the high cold and high altitude in Tibet, the tailings containing the radioactive element thorium should be heated and dried in an oven at 102°C for 15 hours, and then the tailings should be ground. Tailings material with a particle size of less than 0.45mm, and then add water to prepare tailings slurry with a concentration of 65wt%.

[0055] (S.2) Immerse the tailings slurry into the hydrofluoric acid-sulfuric acid system, the volume ratio of hydrofluoric acid to sulfuric acid in the hydrofluoric acid-sulfuric acid system is 1:5, and the mass of tailings slurry to the volume of hydrofluoric acid The ratio is 1 g: 10ml, and the pH value is controlled at 4, the leaching time is 3 hours, and the leaching temperature is 80°C, so that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com