Treatment device for refining asphalt from petroleum by using air blowing method

A processing device and blowing technology, applied in curing/crushing processing tar asphalt/petroleum asphalt/natural asphalt, chemical liquid solidification, etc., can solve the problems of slow curing speed of asphalt, poor airtightness, inability to evaporate moisture and oil collection, etc. , to achieve the effect of reducing trouble and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as figure 1 As shown, a processing device for refining asphalt using air blowing method includes a support 1, a placement frame 2, a placement frame 3, a blowing assembly 4 and a cover assembly 5, and the top of the support 1 is provided with a placement frame 2, and the placement frame 2 There are four placement frames 3 on the left and right sides connected by screws. The placement frames 3 are used to hold asphalt, and the blowing assembly 4 is arranged on the support 1. The blowing assembly 4 is used to solidify the asphalt. A cover assembly 5 is provided, and the cover assembly 5 is used to guide the wind blown out by the blowing assembly 4 .

[0032] When the asphalt needs to be processed, the staff will spread the bag on the placement frame 3. After the completion, the staff will pour the asphalt into the placement frame 3 one by one. The asphalt is located in the bag, and then the staff will connect the external blowing equipment to the blowing On the comp...

Embodiment 2

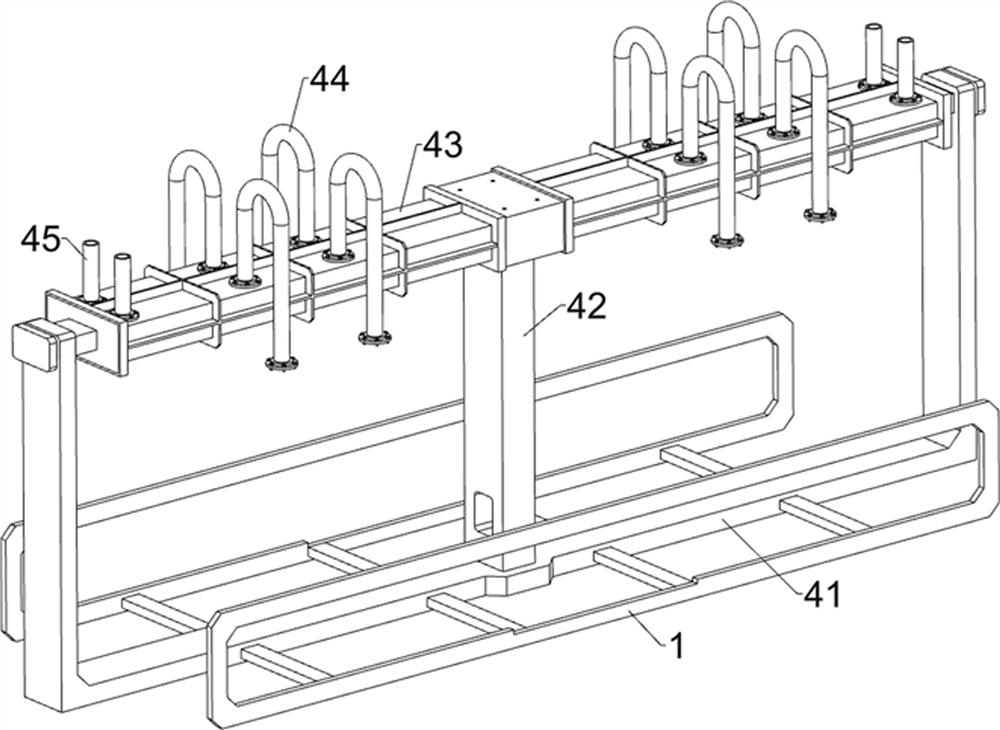

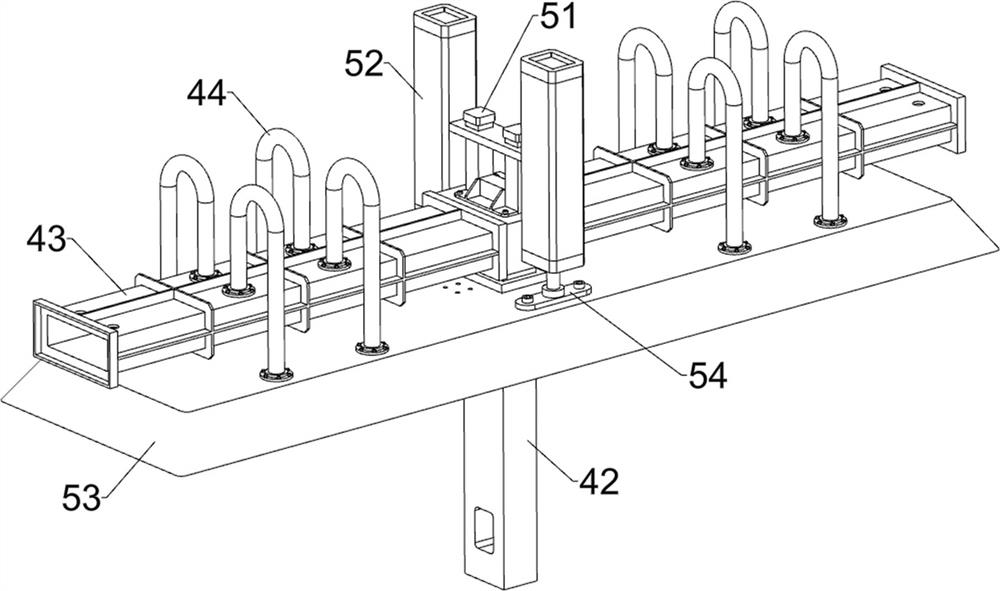

[0034] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, on the basis of Embodiment 1, the blowing assembly 4 includes a fixed frame 41, a pillar 42, a ventilation frame 43, an air outlet hose 44 and an air intake pipe 45, and the middle position of the bracket 1 is welded with a fixed frame 41, and the fixed frame 41 is provided with a pillar 42 at the center of the top, and the top of the pillar 42 is provided with a ventilation frame 43, and the left and right sides of the top of the ventilation frame 43 are all provided with four air outlet hoses 44 connected by screws. On the asphalt, air intake pipes 45 are symmetrically arranged on the left and right sides of the top of the ventilation frame 43 .

[0035] The cover assembly 5 includes a connecting frame 51, an electric push rod 52, a cover frame 53 and a connecting plate 54. The middle part of the ventilation frame 43 is provided with a connecting frame 51 through screw connection, and the connecting fr...

Embodiment 3

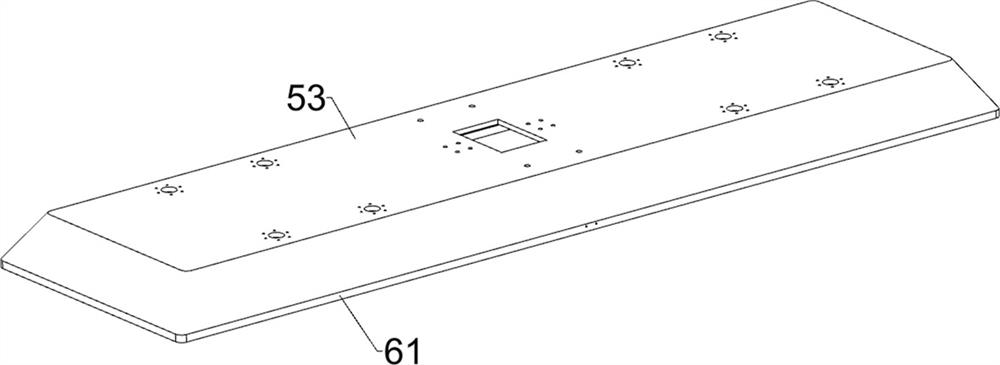

[0038] Such as figure 1 , Figure 5 , Figure 6 , Figure 4 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 12 As shown, on the basis of Embodiment 2, a collection assembly 6 is also included. The collection assembly 6 includes a collection frame 61, a fixed plate 62, a strip frame 63, a blocking block 64, a slide rail 65, a cover plate 66 and a second A spring 67, the bottom of the cover frame 53 is provided with a collection frame 61, the front and rear sides of the middle part of the collection frame 61 are all provided with a fixing plate 62 connected by screws, and the bottom of the two fixing plates 62 are all provided with a strip frame connected by screws 63, the strip frame 63 is used to collect evaporated moisture and oil, and the lower part of the opposite side wall of the strip frame 63 on the front and rear sides is provided with a square hole that can discharge the moisture and oil in the strip frame 63, and the two strips Blocking blocks 64 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com