A kind of waterproof anti-seepage asphalt coating and preparation method thereof

An asphalt coating, waterproof and anti-seepage technology, applied in asphalt coatings, coatings, etc., can solve the problems of reducing the service life of asphalt coatings, low anti-seepage and water resistance, and falling off, and achieve strong waterproof and anti-seepage capabilities, excellent waterproof and anti-seepage Permeability, increase the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

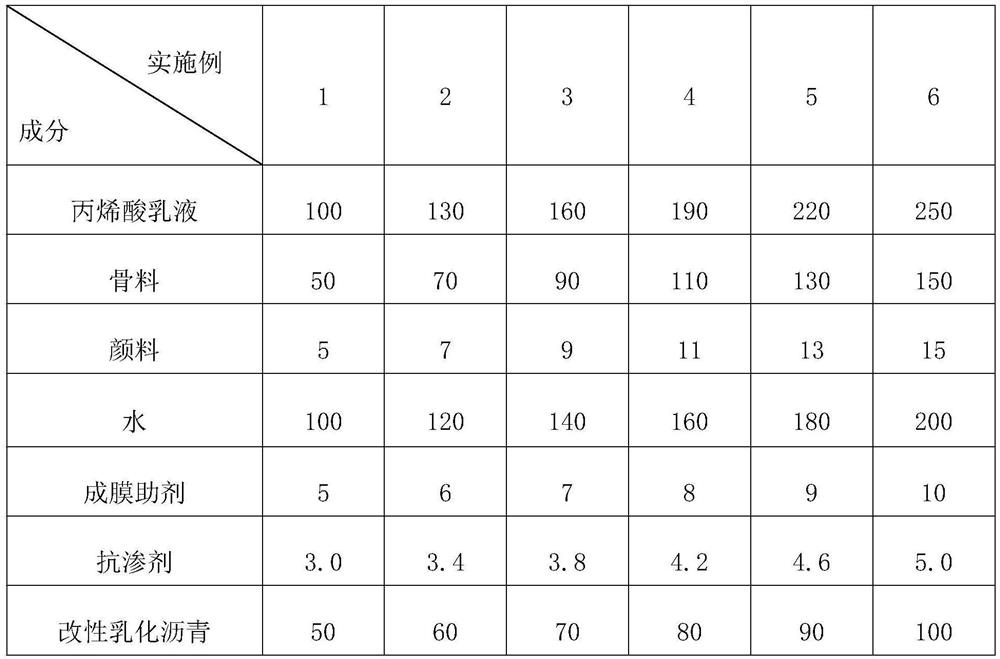

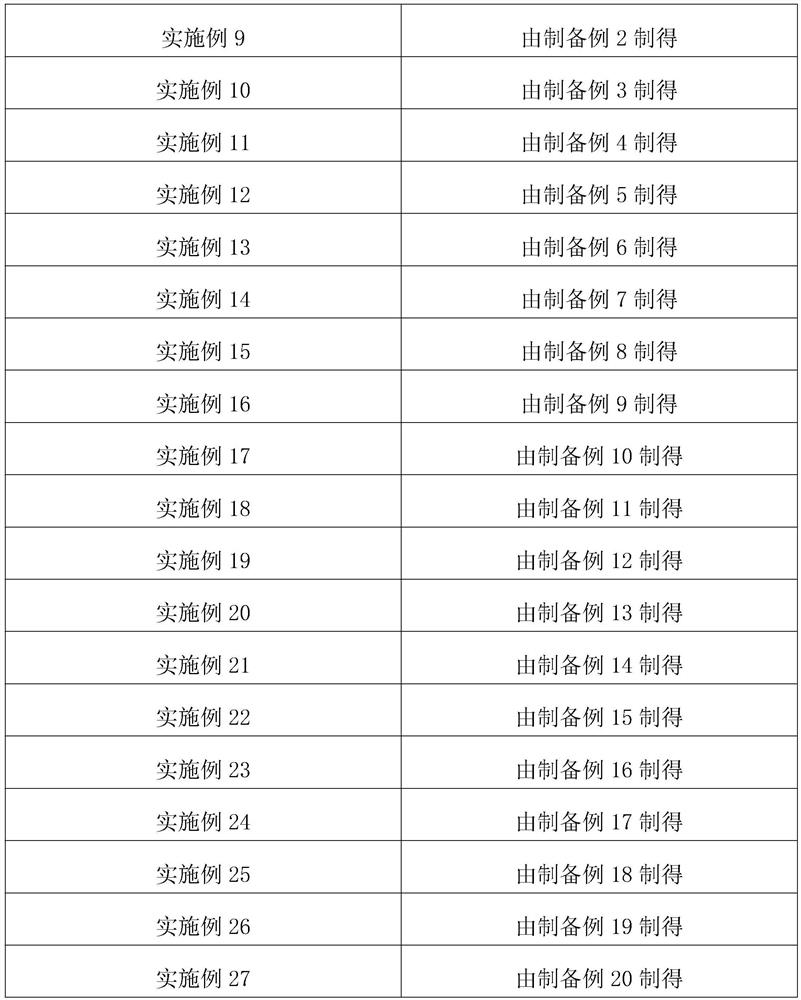

Examples

preparation example 1

[0054] A kind of modified emulsified asphalt, its preparation steps are as follows:

[0055] The emulsified asphalt and modified liquid are in a weight ratio of 1:0.3, under the condition of pH 4, vacuumize, heat to 100°C, and stir at a speed of 2500r / min for 20min to prepare modified emulsified asphalt;

[0056] The modified liquid is composed of modified colloid and modified filler in a weight ratio of 1:0.05;

[0057] The modified colloid is composed of hyperbranched polyamide resin, starch and tributyl phosphate in a weight ratio of 1:0.3:0.01;

[0058]The modified filler is nano silica powder.

preparation example 2

[0060] A modified emulsified asphalt, the difference from Preparation Example 1 is that the emulsified asphalt and modified liquid are in a weight ratio of 1:0.3, under the condition of pH 5, vacuumize, and heat to 110°C, at 2750r / min The modified emulsified asphalt can be prepared by stirring at a constant speed for 25 minutes.

preparation example 3

[0062] A modified emulsified asphalt, the difference from Preparation Example 1 is that the emulsified asphalt and the modified liquid are in a weight ratio of 1:0.3, under the condition of pH 6, vacuumize, and heat to 120°C, at 2750r / min The modified emulsified asphalt can be prepared by stirring at a constant speed for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com