Dry hanging self-decoration anti-seepage insulation board for external wall

An external wall insulation board and dry-hanging technology, which is applied in the direction of covering/lining, building, building structure, etc., can solve the problems of water leakage and water seepage, lack of anti-seepage function, etc., to reduce construction costs, and the installation method is firm and reliable. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

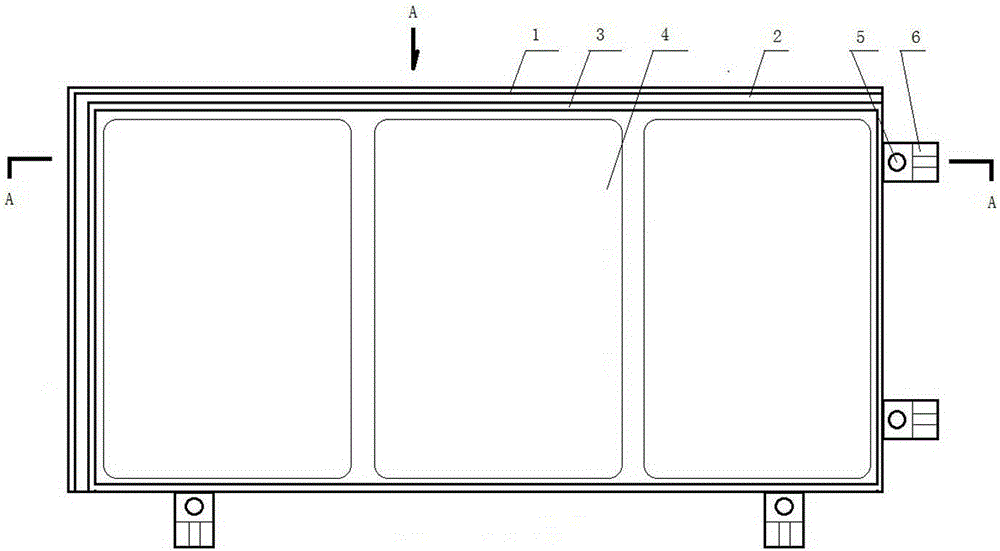

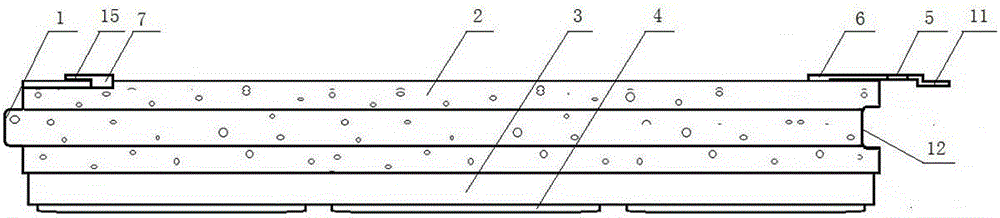

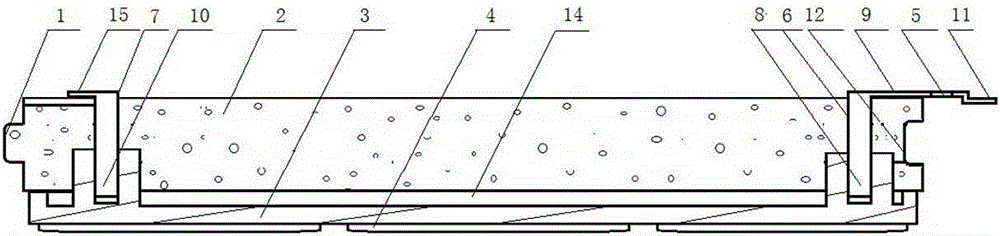

[0029] The dry-hanging self-decorating anti-seepage external wall insulation board provided by the present invention is composed of a panel 3 and an insulation layer 2. At least two sides of the insulation layer 2 are each wider than the corresponding sides of the panel 3 by 1mm-20mm. An anti-seepage protrusion or / and an anti-seepage groove is arranged on the side of the layer.

[0030] The setting of the anti-seepage protrusion and the anti-seepage groove can be combined arbitrarily according to the actual situation. The two sides of the insulation layer can be provided with anti-seepage protrusions, and the other two sides are respectively provided with the anti-seepage protrusions. Cooperate with the anti-seepage groove installed; it is also possible to set anti-seepage protrusions or anti-seepage grooves on all four sides of the insulation layer. When installing, set the insulation board with anti-seepage protrusion and the insulation board with anti-seepage groove It can ...

Embodiment 2

[0033] like Figure 4 , Figure 5 , Figure 10 As shown, the outer wall insulation board used for the corner column, the side of the insulation layer is provided with an edge banding plate 16, and the edge banding plate 16 is connected with the panel 3 as a whole; the inner surface of the insulation layer 2 is provided with an anti-seepage The protrusion 17 or the anti-seepage groove 18 is installed in cooperation with the anti-seepage groove 12 or the anti-seepage protrusion 1 on the side of the insulation layer respectively. The flexible caulking material 19 is embedded in the board seam between the adjacent panels 3 to realize waterproof and anti-seepage of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com