Freeze-thaw resistant waterproof mortar and preparation method thereof

A waterproof mortar and freeze-thaw resistant technology, which is applied in the field of building materials, can solve the problems of mortar strength and cohesion reduction, mortar durability reduction, mortar aging, frost cracking, etc., to reduce water-binder ratio, reduce porosity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

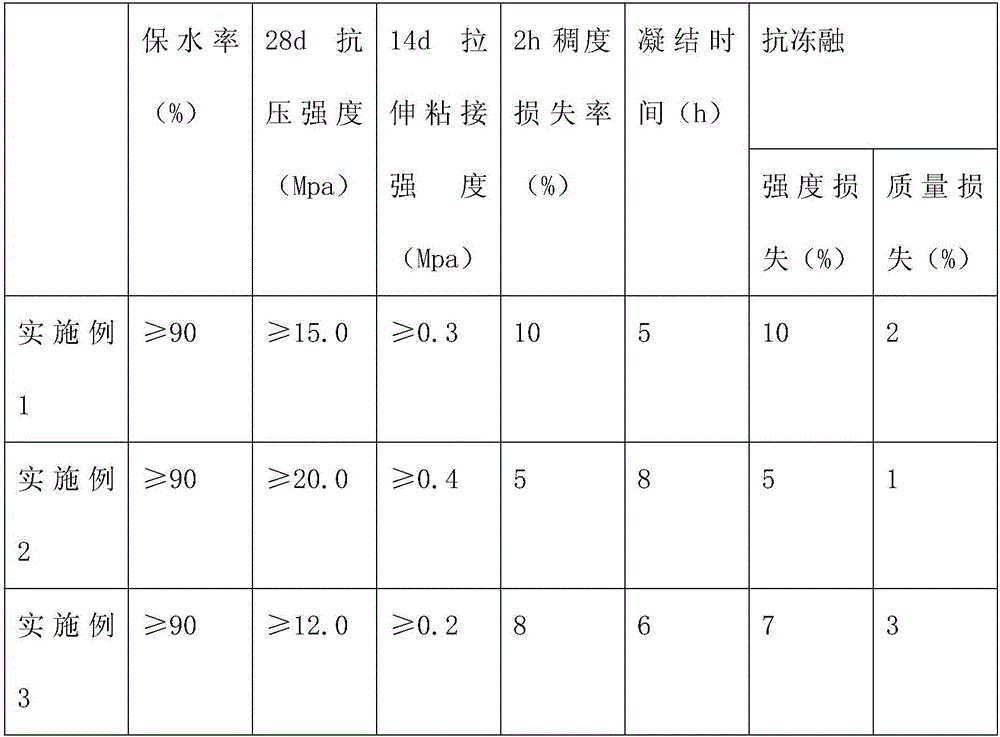

Embodiment 1

[0020] A freeze-thaw resistant waterproof mortar, made of the following raw materials in parts by weight: 100 parts of cement, 20 parts of river sand, 10 parts of potato waste powder, 30 parts of rubber powder, 5 parts of methyl cellulose ether, and 5 parts of polypropylene fiber , 20 parts of sepiolite powder, 5 parts of rutile titanium dioxide, 5 parts of modified fly ash, 10 parts of gypsum, 1 part of expansion agent, 1 part of defoaming agent, 1 part of water reducing agent, 3 parts of waterproofing agent, cold resistance agent 2 copies;

[0021] The potato waste residue powder is obtained by air-drying the potato waste residue produced by a potato starch production enterprise, crushing it, passing through a 200-mesh sieve, soaking it in dimethyl methyl phosphate for 10 hours, separating it, and drying it naturally to obtain the potato waste residue powder.

[0022] The rubber powder is a polyvinyl acetate-ethylene emulsion spray-dried, and 10% of the total weight of the f...

Embodiment 2

[0030] A freeze-thaw resistant waterproof mortar, made of the following raw materials in parts by weight: 110 parts of cement, 22 parts of river sand, 15 parts of potato waste powder, 50 parts of rubber powder, 6 parts of methyl cellulose ether, and 6 parts of polypropylene fiber , 15 parts of sepiolite powder, 6 parts of rutile titanium dioxide, 7 parts of modified fly ash, 11 parts of gypsum, 2 parts of expansion agent, 2 parts of defoaming agent, 2 parts of water reducing agent, 2 parts of waterproofing agent, cold resistance agent 3 copies;

[0031] The potato waste residue powder is obtained by air-drying the potato waste residue produced by a potato starch production enterprise, crushing it, passing through a 300-mesh sieve, soaking it in dimethyl methyl phosphate for 8 hours, separating it, and drying it naturally to obtain the potato waste residue powder.

[0032] The rubber powder is a polyvinyl acetate-ethylene emulsion spray-dried, and 10% of the total weight of the...

Embodiment 3

[0040] A freeze-thaw resistant waterproof mortar, made of the following raw materials in parts by weight: 120 parts of cement, 20 parts of river sand, 20 parts of potato waste powder, 30 parts of rubber powder, 8 parts of methyl cellulose ether, and 5 parts of polypropylene fiber , 20 parts of sepiolite powder, 5 parts of rutile titanium dioxide, 8 parts of modified fly ash, 12 parts of gypsum, 3 parts of expansion agent, 3 parts of defoaming agent, 3 parts of water reducing agent, 1 part of waterproofing agent, cold resistance agent 2 copies;

[0041] The potato waste residue powder is prepared by air-drying the potato waste residue produced by a potato starch production enterprise, pulverizing, passing through a 300-mesh sieve, soaking in dimethyl methyl phosphate for 5 hours, separating, and drying naturally to obtain the potato waste residue powder.

[0042] The rubber powder is a polyvinyl acetate-ethylene emulsion spray-dried, and 10% of the total weight of the finished pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com