Multi-component extrusion-type mortar as well as preparation method and use method thereof

A multi-component, mortar technology, applied in the direction of clay preparation equipment, chemical instruments and methods, cement mixing equipment, etc., can solve problems such as difficulties in the application of special masonry projects, and achieve improved extrusion effects, good storage stability, and reduced The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The proportioning of the extrusion mortar of the present embodiment is by mass:

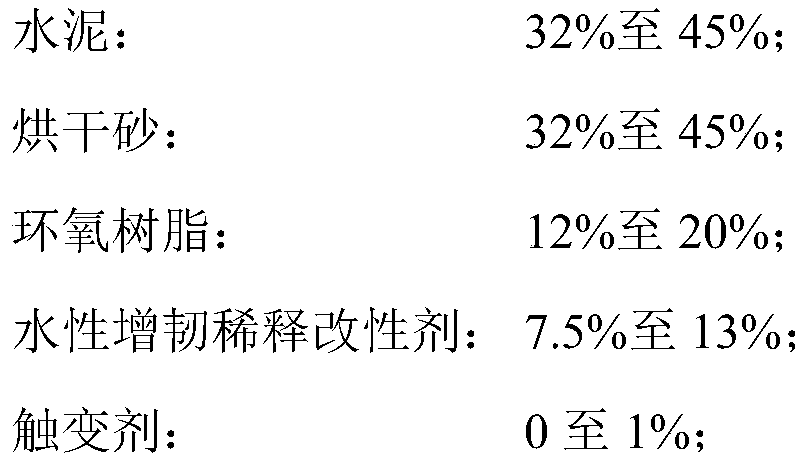

[0041] The raw materials of component A are calculated by mass fraction as:

[0042]

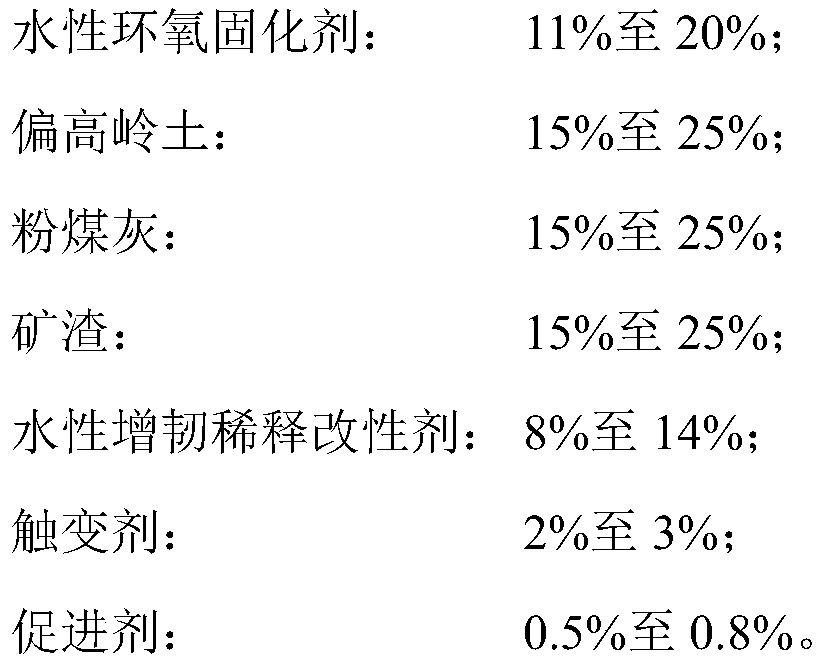

[0043] The raw materials of component B are calculated by mass fraction as:

[0044]

[0045] C component is water;

[0046] The mass ratio of component A, component B and component C is 3.0:1:0.3.

Embodiment 2

[0048] The proportioning of the extrusion mortar of the present embodiment is by mass:

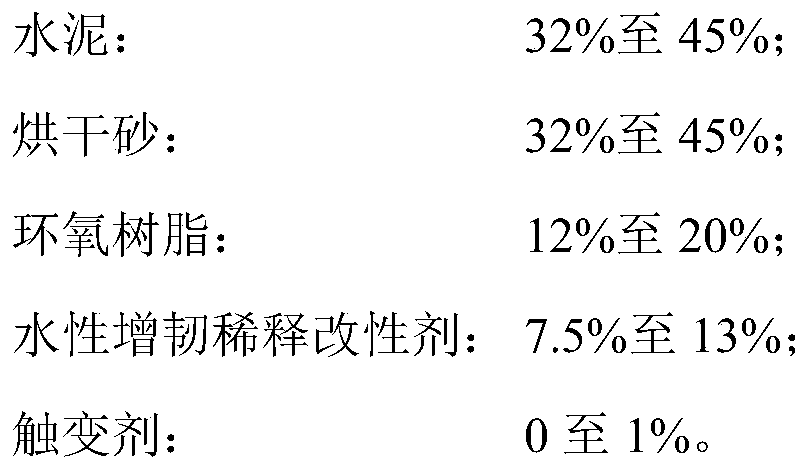

[0049] The raw materials of component A are calculated by mass fraction as:

[0050]

[0051]

[0052]The raw materials of component B are calculated by mass fraction as:

[0053]

[0054] C component is water;

[0055] The mass ratio of component A, component B and component C is 3.1:1:0.3.

Embodiment 3

[0057] The proportioning of the extrusion mortar of the present embodiment is by mass:

[0058] The raw materials of component A are calculated by mass fraction as:

[0059]

[0060] The raw materials of component B are calculated by mass fraction as:

[0061]

[0062] C component is water;

[0063] The mass ratio of component A, component B and component C is 3.8:1:0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com