a tile grout

A technology of caulking agent and ceramic tile, which is applied in the field of tile caulking agent, can solve the problems of alkali/salt return, poor impermeability and other problems, and achieve the effects of low cost, convenient construction, and excellent waterproof and impermeable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

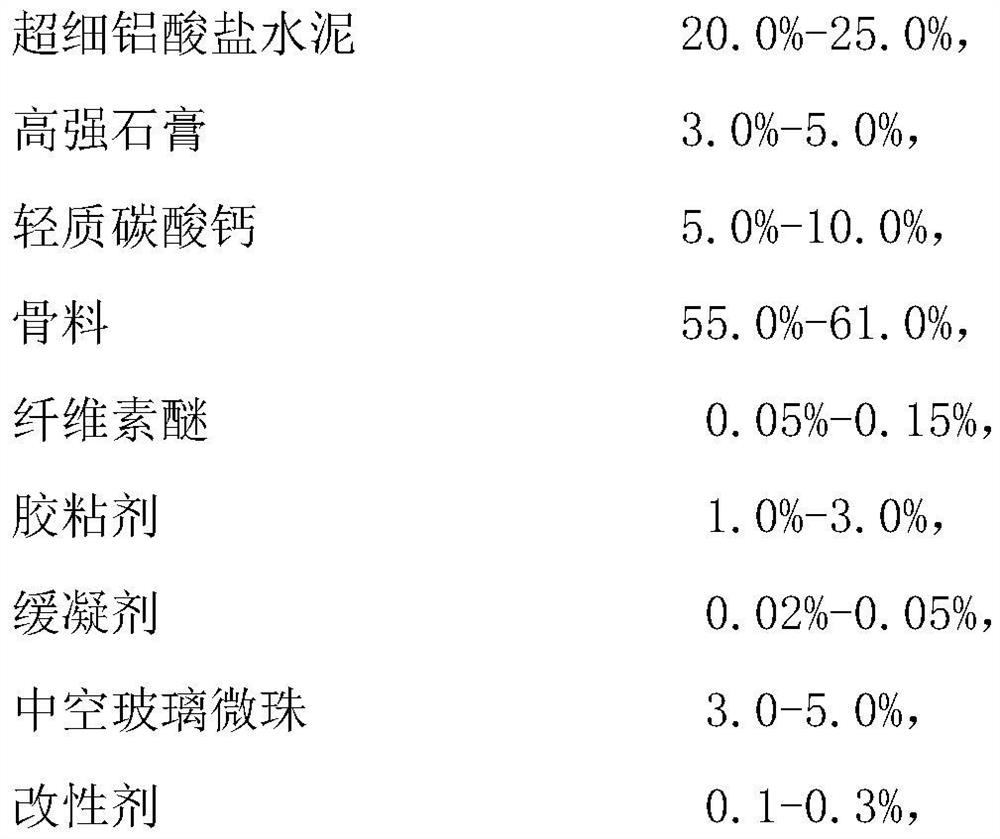

Method used

Image

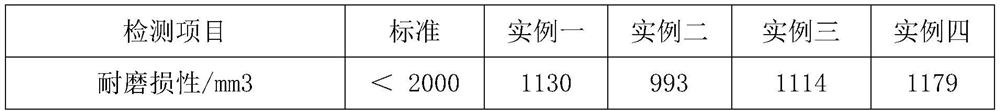

Examples

Embodiment 1

[0033] Prepare the raw materials according to the formula: superfine aluminate cement C80 200kg, high-strength gypsum 30kg, light calcium carbonate 100kg, 80-120 mesh quartz sand 605kg, 25000mPa.s cellulose ether 1.5kg, acrylate and styrene copolymer powder 30kg, 0.2kg of sodium citrate, 30kg of hollow glass beads, 3kg of modifier, 0.3kg of iron oxide black; mix and stir the above-mentioned raw materials to obtain tile grout.

Embodiment 2

[0035] Prepare the raw materials according to the formula: superfine aluminate cement C70 250kg, high-strength gypsum 50kg, light calcium carbonate 50kg, 80-120 mesh quartz sand 580kg, 40000mPa.s cellulose ether 0.5kg, acrylate and styrene copolymer powder 20kg, 0.5kg of sodium citrate, 45kg of hollow glass microspheres, 1kg of modifier, and 3kg of red iron oxide; mix and stir the above-mentioned raw materials to obtain the ceramic tile grout.

Embodiment 3

[0037] Prepare the raw materials according to the formula: superfine aluminate cement C70 225kg, high-strength gypsum 40kg, light calcium carbonate 75kg, 80-120 mesh quartz sand 600kg, 40000mPa.s cellulose ether 1kg, acrylate and styrene copolymer powder 10kg , 0.3kg of sodium citrate, 30kg of hollow glass microspheres, 2kg of modifier, and 16.7kg of iron oxide brown; mix and stir the above-mentioned raw materials to obtain a ceramic tile grout.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com