Self-adhesive waterproof roll structure

A waterproof membrane, self-adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, synthetic resin layered products, etc., can solve the problems of leakage at the splicing, waste of coils, etc., to achieve high self-adhesive, The effect of long service life and guaranteed thickness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

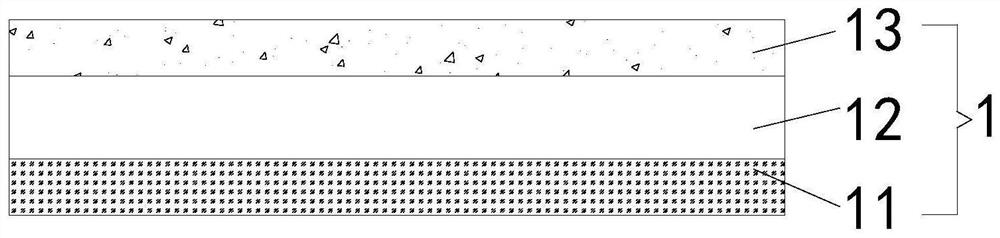

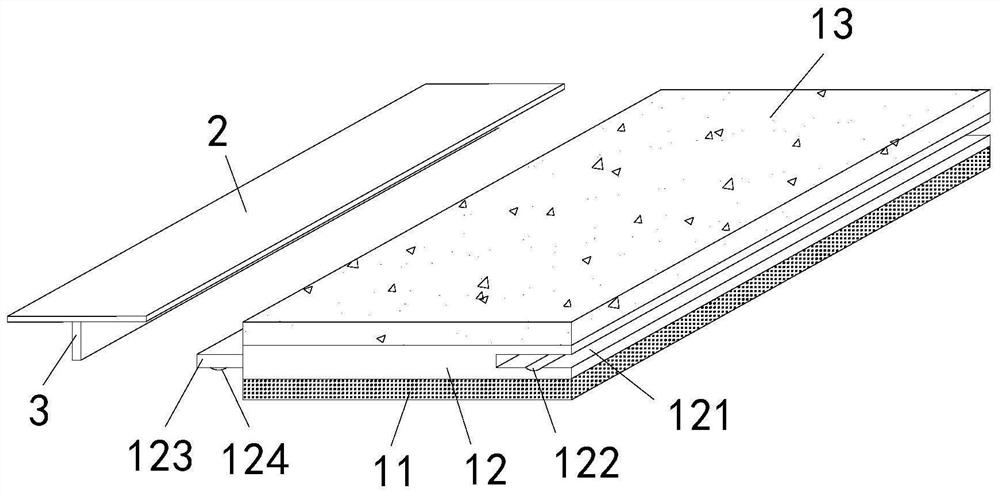

[0040] refer to Figure 1-3 , a self-adhesive waterproof membrane structure, including a waterproof membrane body 1 and a waterproof cover layer 2, the waterproof membrane body 1 is sequentially laminated by a base layer 11, a composite waterproof layer 12 and an adhesive layer 13 from bottom to top One side of the composite waterproof layer 12 is provided with a plug-in layer 123, and the bottom of the plug-in layer 123 is provided with a convex strip 124; the other side of the composite waterproof layer 12 is provided with a mounting clip corresponding to the plug-in layer 123 Groove 121, the bottom of the installation clip groove 121 is provided with a concave groove 122 corresponding to the convex strip 124;

[0041] The middle part of the lower end of the waterproof cover layer 2 is provided with a sealing strip 3. During implementation, align the inserting layer 123 on one side of the coil with the installation clip groove 121 on the other side of the coil, and insert th...

Embodiment 2

[0059] refer to Figure 1-3 , a self-adhesive waterproof membrane structure, including a waterproof membrane body 1 and a waterproof cover layer 2, the waterproof membrane body 1 is sequentially laminated by a base layer 11, a composite waterproof layer 12 and an adhesive layer 13 from bottom to top One side of the composite waterproof layer 12 is provided with a plug-in layer 123, and the bottom of the plug-in layer 123 is provided with a convex strip 124; the other side of the composite waterproof layer 12 is provided with a mounting clip corresponding to the plug-in layer 123 Groove 121, the bottom of the installation clip groove 121 is provided with a concave groove 122 corresponding to the convex strip 124;

[0060] The middle part of the lower end of the waterproof cover layer 2 is provided with a sealing strip 3. During implementation, align the inserting layer 123 on one side of the coil with the installation clip groove 121 on the other side of the coil, and insert th...

Embodiment 3

[0078] refer to Figure 1-3 , a self-adhesive waterproof membrane structure, including a waterproof membrane body 1 and a waterproof cover layer 2, the waterproof membrane body 1 is sequentially laminated by a base layer 11, a composite waterproof layer 12 and an adhesive layer 13 from bottom to top One side of the composite waterproof layer 12 is provided with a plug-in layer 123, and the bottom of the plug-in layer 123 is provided with a convex strip 124; the other side of the composite waterproof layer 12 is provided with a mounting clip corresponding to the plug-in layer 123 Groove 121, the bottom of the installation clip groove 121 is provided with a concave groove 122 corresponding to the convex strip 124;

[0079] The middle part of the lower end of the waterproof cover layer 2 is provided with a sealing strip 3. During implementation, align the inserting layer 123 on one side of the coil with the installation clip groove 121 on the other side of the coil, and insert th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com