A germanium solar cell and its preparation method and application

A solar cell and battery technology, applied in the field of solar cells, can solve problems such as the heavy weight of germanium solar cells and the inability to achieve flexibility, and achieve the effects of increasing battery life, reducing gas resistance, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

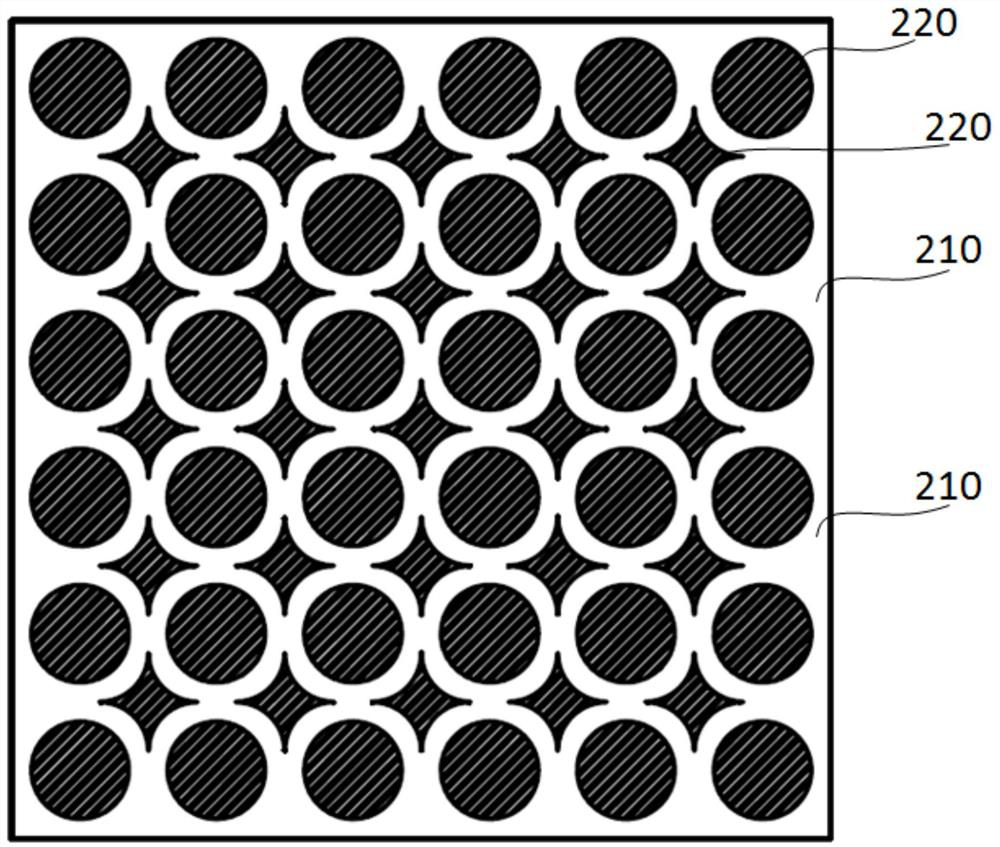

Image

Examples

Embodiment 1

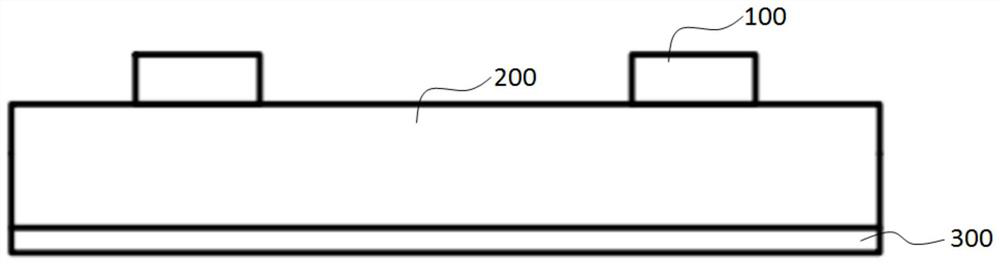

[0102] This embodiment prepares a germanium solar cell, and the specific process is as follows:

[0103] D1. Use MOCVD method to grow the middle cell and top cell of the solar cell epitaxial wafer 300 on the surface of the germanium substrate 200;

[0104]D2. Cleaning the parts obtained in step D1, specifically, cleaning with acetone for 10min, isopropanol for 10min, rinsing with water, and drying;

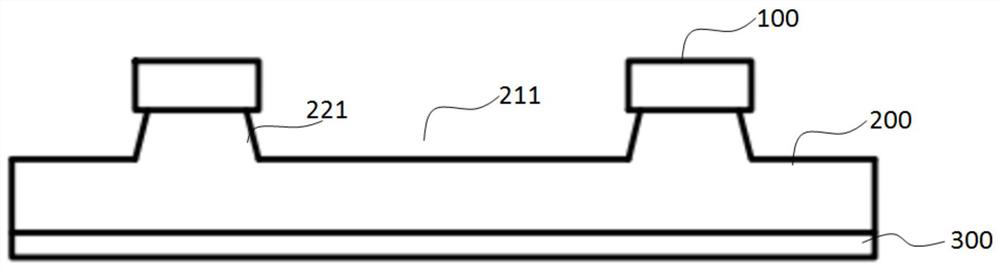

[0105] D3. Perform photolithography protection on the parts obtained in step D2, specifically using negative photoresist, and developing exposure energy of 230mj;

[0106] D4. thermally evaporate and add metal to the parts obtained in step D3, the instrument used is an atomic beam evaporation coating machine, and the specific composition of positive gold is: along the epitaxial layer 300 away from the surface of the germanium substrate 200, AuGeNi layer, Au layer, Ag layer and Au layer;

[0107] D5. Use a blue film stripper to remove the photoresist set in step D3. The specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com