Stretchable calotropis gigantean fiber graphene flexible sensor

A flexible sensor and horn melon fiber technology, which is applied in plant fiber, fiber processing, biochemical fiber processing, etc., can solve the problems of decreased accuracy of test tension, poor sensing durability, poor durability, etc., and achieve good radial tensile performance , reduce wear and damage, increase durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

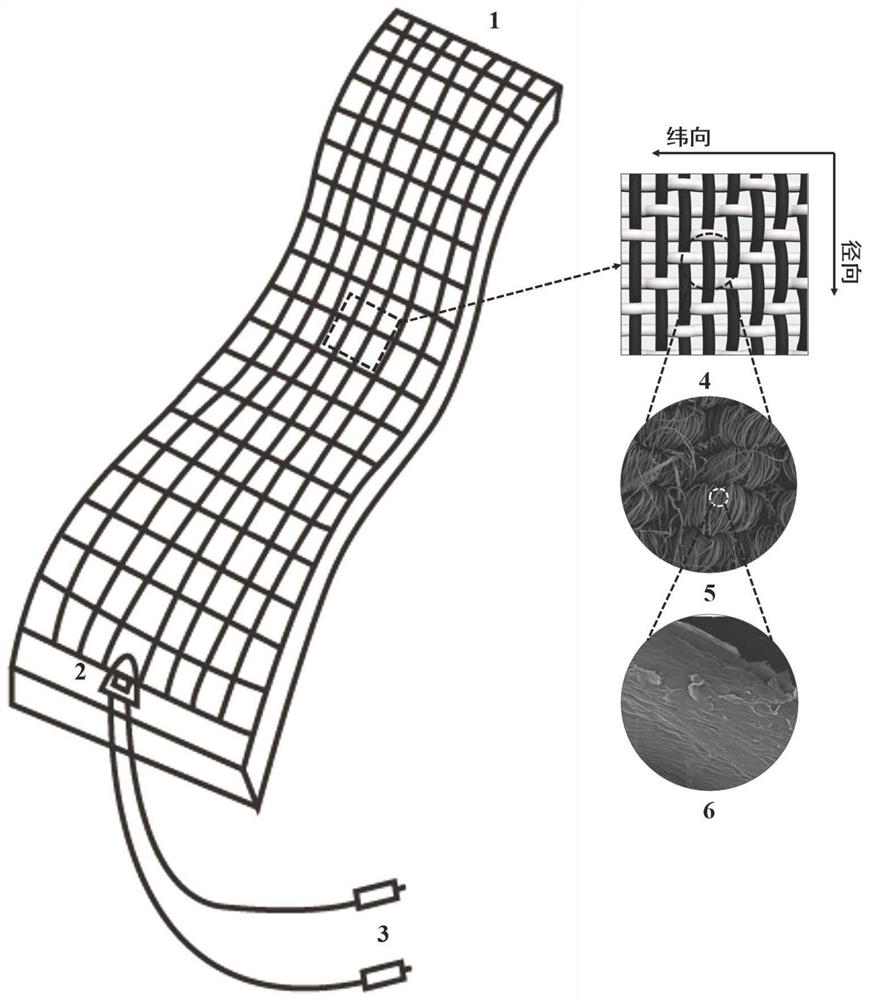

[0041] Such as Figure 1-3 and Figure 5 Shown, in the present invention, conductive flexible gourd fabric layer 4 comprises the following preparation steps:

[0042] S11: Place the croissant melon yarn in Na 2 CO 3 Washed in solution, Na 2 CO 3 The concentration of the solution is 20g / L, the washing time is 50min, the washing temperature is 45°C, and the washing bath ratio is 1:300. After washing, the croissant melon yarn is cleaned with deionized water to remove the impurities remaining on its surface, and then Place in an oven and dry at 60°C for 1 hour;

[0043] S12: 1-4g graphite, 1-4gNaNO 3 Mix in 100 mL of H 2 SO 4 , keep stirring in an ice bath, add 3-12g potassium permanganate during stirring, after stirring, add 150-600mL deionized water in stages, and then add appropriate amount of H 2 o 2 Terminate the reaction, obtain a graphene oxide solution by high-speed centrifugation with HCL and water, and adjust the concentration of the graphene oxide solution to ...

Embodiment 2

[0055] Among the present invention, conductive flexible croissantica fabric layer 4 comprises the following preparation steps:

[0056] S21: Wash the croissant melon yarn in NaOH solution, the concentration of NaOH solution is 20g / L, the washing time is 60min, the washing temperature is 30°C, the washing bath ratio is 1:500, and deionized water is used to treat the croissant melon yarn after washing. After the yarn is cleaned to remove impurities remaining on its surface, it is placed in an oven to dry at 30°C for 1 hour;

[0057] S22: 1-4g graphite, 1-4g NaNO 3 Mix in 100mLH 2 SO 4 , keep stirring in an ice bath, add 3-12g potassium permanganate during stirring, after stirring, add 150-600mL deionized water in stages, and then add appropriate amount of H 2 o 2 Terminate the reaction, obtain a graphene oxide solution by high-speed centrifugation with HCL and water, and adjust the concentration of the graphene oxide solution to 3 mg / mL;

[0058] S23: Soak the horned melon ...

Embodiment 3

[0066] Among the present invention, conductive flexible croissantica fabric layer 4 comprises the following preparation steps:

[0067] S31: Place the croissant melon yarn in Na 2 CO 3 Washed in solution, Na 2 CO 3 The concentration of the solution is 30g / L, the washing time is 40min, the washing temperature is 60°C, and the washing bath ratio is 1:400. After washing, the croissant melon yarn is cleaned with deionized water to remove the residual impurities on the surface, and then Place in an oven and dry at 50°C for 1 hour;

[0068] S33: 1-4g graphite, 1-4gNaNO 3 Mix in 100mLH 2 SO 4 , keep stirring in an ice bath, add 3-12g potassium permanganate during stirring, after stirring, add 150-600mL deionized water in stages, and then add appropriate amount of H 2 o 2 Terminate the reaction, obtain a graphene oxide solution by high-speed centrifugation with HCL and water, and adjust the concentration of the graphene oxide solution to 7 mg / mL;

[0069] S33: Soak the squash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com