Overlying strata isolation grouting filling method for underground emission reduction of coal gangue

A technology for isolating grouting and coal gangue, which is applied in the fields of filling, drilling equipment and methods, earthwork drilling, etc., can solve the problems such as the inability to deal with coal gangue, the inability to set up grouting holes, and the inability to construct drilling holes, etc. Achieve the effect of small deformation, reduce lifting cost and increase grouting amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] DRAWINGS The present invention is further described:

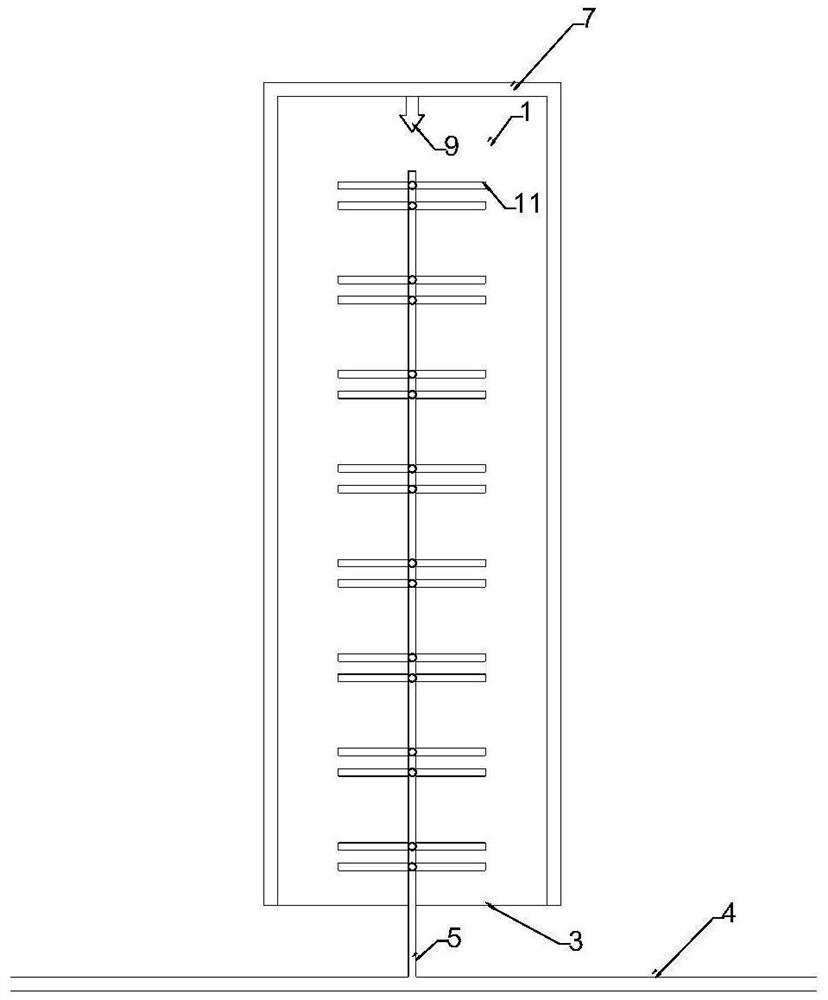

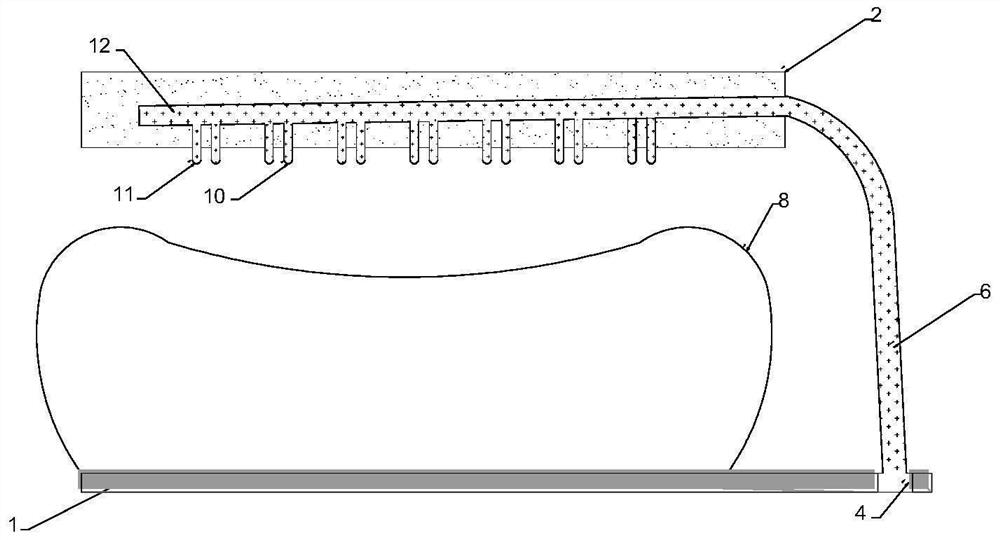

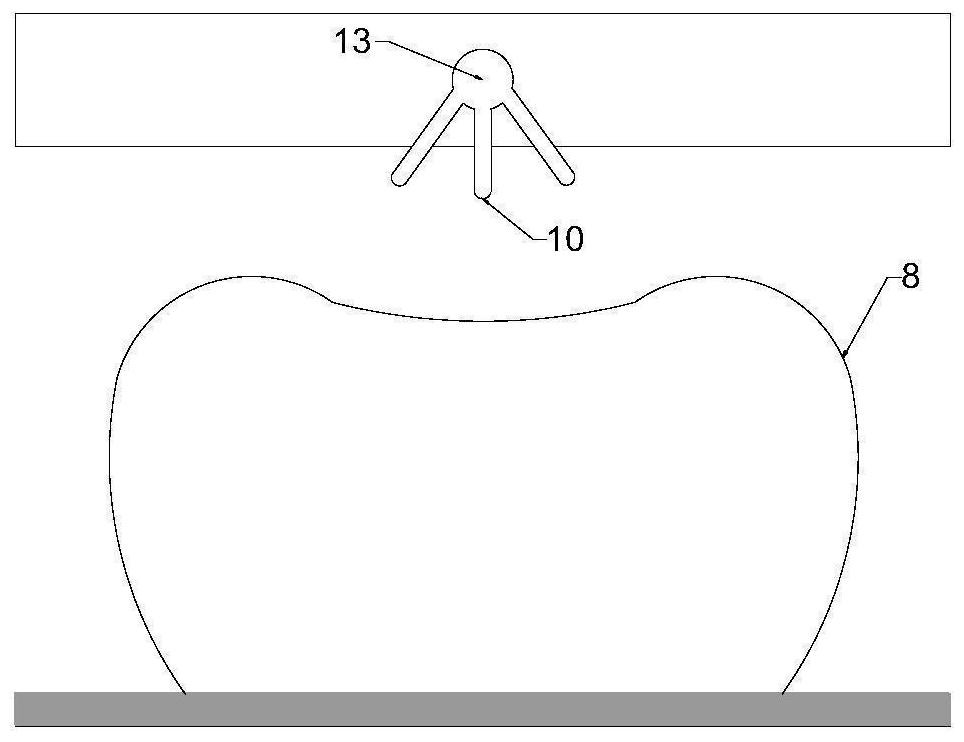

[0034] like figure 1 , The reduction of the present invention with gangue overburden isolated grouting method, comprising the steps of:

[0035] a. The parameter extraction, geological information coal face 1, the key discriminated layered rocks, subsidence control and filling process according to the amount of gangue demand surface, wherein the selected critical layer having a thickness larger as grouting key filling layer 2, the key grouting under interfacial layer 2 is the selected bit of the grouting layer;

[0036] b. From the coal face mining terminal line 3 outside the tunnel 4 (e.g., mountain tunnel, etc.), select a location as the drill field, filling layer 2 Construction of a direction key hole 5 from downhole directional drilling field to the grouting, downhole directional drilling hole 5 is inclined hole 6 opened, the opening direction is a tangential direction of the mining face 7 of the eye, from the angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com