Overlying Rock Isolation Grouting Filling Method for Coal Gangue Underground Emission Reduction

A technology for isolating grouting and coal gangue, which is applied in fillings, drilling equipment and methods, directional drilling, etc. Small, reduce the cost of upgrading, and avoid the effect of occupying land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

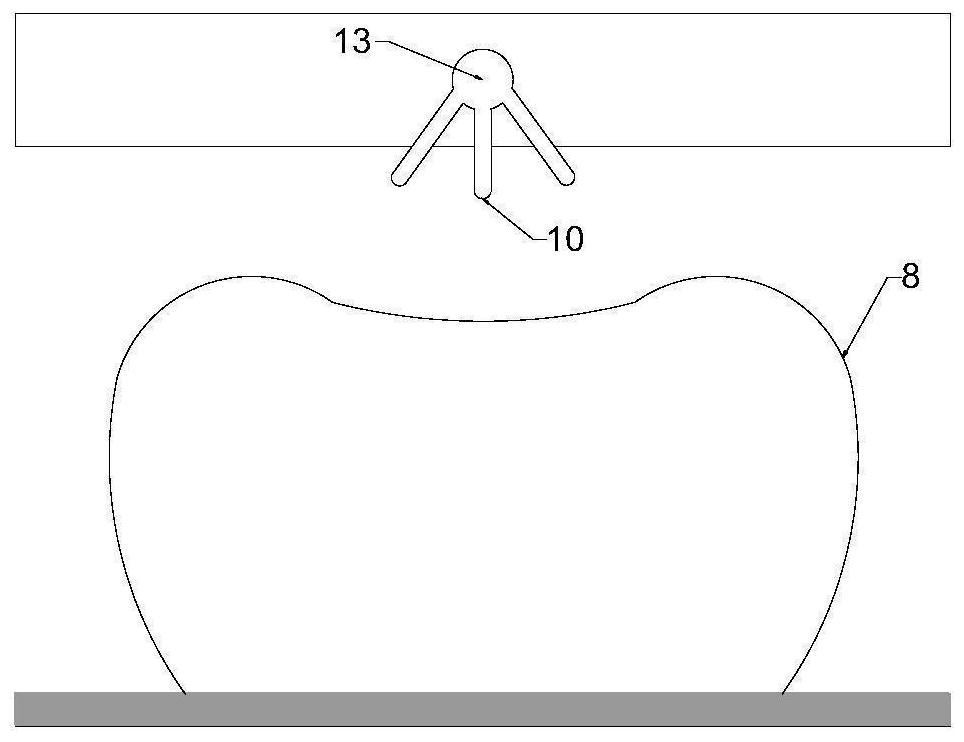

[0033] Below in conjunction with accompanying drawing, the present invention is further described:

[0034] like figure 1 As shown, the overlying rock isolation grouting filling method for reducing the emission of coal gangue underground of the present invention includes the following steps:

[0035] a. According to the mining parameters and geological information of the coal mining face 1, identify the key layers in the overlying rock, and select one of the key layers with larger thickness as grouting according to the requirements of surface subsidence control and gangue filling capacity Filling the key layer 2, the lower interface of the key layer 2 is the selected grouting filling layer;

[0036] b. From the roadway 4 outside the final mining line 3 of the coal mining face (such as the uphill roadway, etc.), select a position as the drilling field, and construct a downhole directional hole 5 in the direction of grouting and filling the key layer 2 from the drilling field, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com