Automobile air filter assembly

An air filter and filter technology, applied in the field of filters, can solve the problems of poor performance of paper-based materials and brittle mechanical properties of filter elements, improve mechanical properties and flame retardancy, improve flexibility and The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

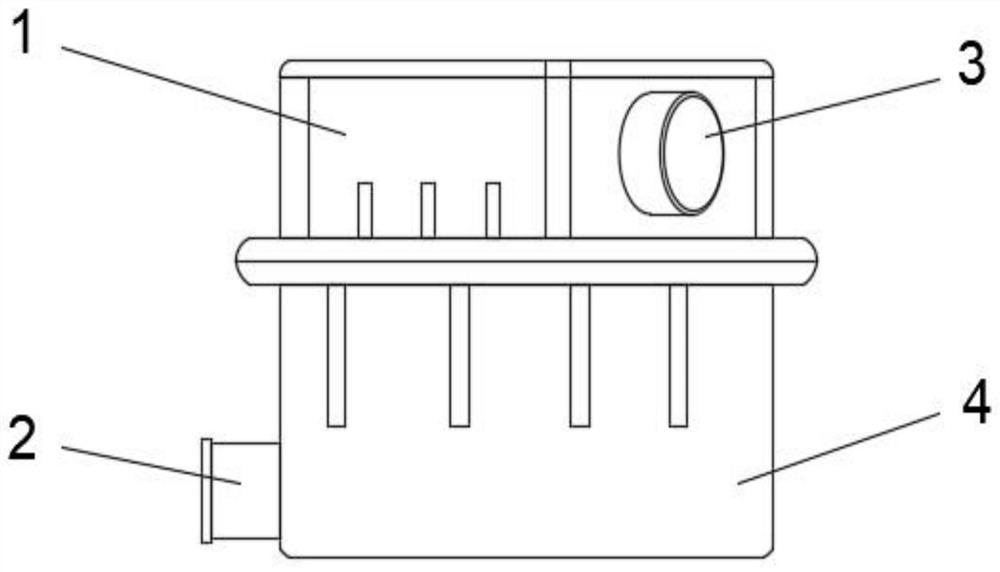

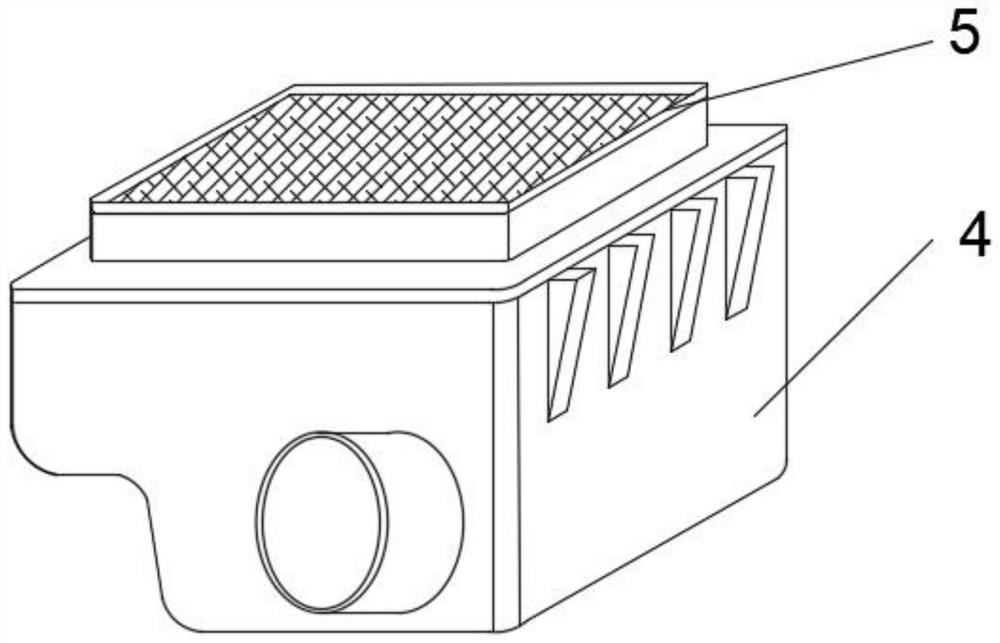

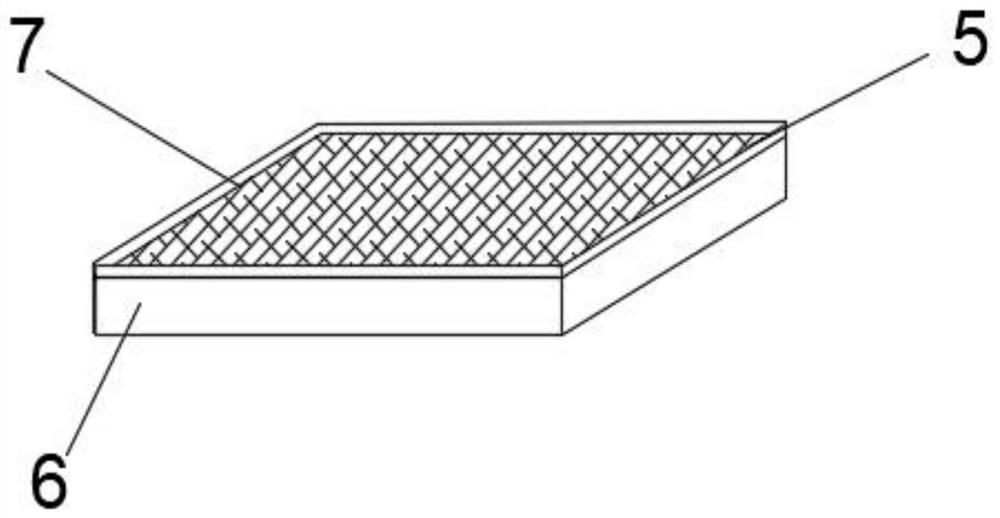

[0040] This embodiment is an automobile air filter assembly. The modified silicone reinforced filter paper layer 6 and the flame retardant layer 7 are prepared according to the conventional production method of the filter element 5, and then the filter element 5 is installed in the lower shell of the filter. 4, the filter upper case 1 is installed to form the automobile air filter assembly;

[0041] Wherein the modified silicone reinforced filter paper layer 6 is prepared by the following steps:

[0042] S1: Add dry chloroplatinic acid to the distilled and dried isopropanol solution, and stir to obtain a catalyst;

[0043] S2: Add glycidyl methacrylate, toluene, an inert solvent, and a catalyst to a three-necked flask equipped with a thermometer, a condenser, a stirrer, and a water separator, heat up to 65°C under stirring, reflux for 1 hour, and dropwise add Hydrogen silicone oil, control the dropping rate at 1 drop / s, raise the temperature to 85°C, add allyl polyoxyethylene...

Embodiment 2

[0052] This embodiment is an automobile air filter assembly. The modified silicone reinforced filter paper layer 6 and the flame retardant layer 7 are prepared according to the conventional production method of the filter element 5, and then the filter element 5 is installed in the lower shell of the filter. 4, the filter upper case 1 is installed to form the automobile air filter assembly;

[0053] Wherein the modified silicone reinforced filter paper layer 6 is prepared by the following steps:

[0054] S1: Add dry chloroplatinic acid to the distilled and dried isopropanol solution, and stir to obtain a catalyst;

[0055] S2: Add glycidyl methacrylate, toluene, an inert solvent, and a catalyst to a three-necked flask equipped with a thermometer, a condenser, a stirrer, and a water separator, heat up to 65°C under stirring, reflux for 1 hour, and dropwise add Hydrogen silicone oil, control the dropping rate at 1 drop / s, raise the temperature to 85°C, add allyl polyoxyethylene...

Embodiment 3

[0064] This embodiment is an automobile air filter assembly. The modified silicone reinforced filter paper layer 6 and the flame retardant layer 7 are prepared according to the conventional production method of the filter element 5, and then the filter element 5 is installed in the lower shell of the filter. 4, the filter upper case 1 is installed to form the automobile air filter assembly;

[0065] Wherein the modified silicone reinforced filter paper layer 6 is prepared by the following steps:

[0066] S1: Add dry chloroplatinic acid to the distilled and dried isopropanol solution, and stir to obtain a catalyst;

[0067] S2: Add glycidyl methacrylate, inert solvent toluene and catalyst to a three-necked flask equipped with a thermometer, condenser, stirrer and water separator, raise the temperature to 75°C under stirring, reflux for 2 hours for dehydration, and dropwise add Hydrogen silicone oil, control the dropping rate at 2 drops / s, raise the temperature to 95°C, add all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com