Method for preparing calcium sulfate by using calcium chloride

A technology of calcium sulfate and calcium chloride, applied in the field of hydrometallurgy, can solve the problems of low output, high cost, limited application of whiskers, etc., and achieves low equipment investment cost, simple and easy-to-control operation, and large industrial potential value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

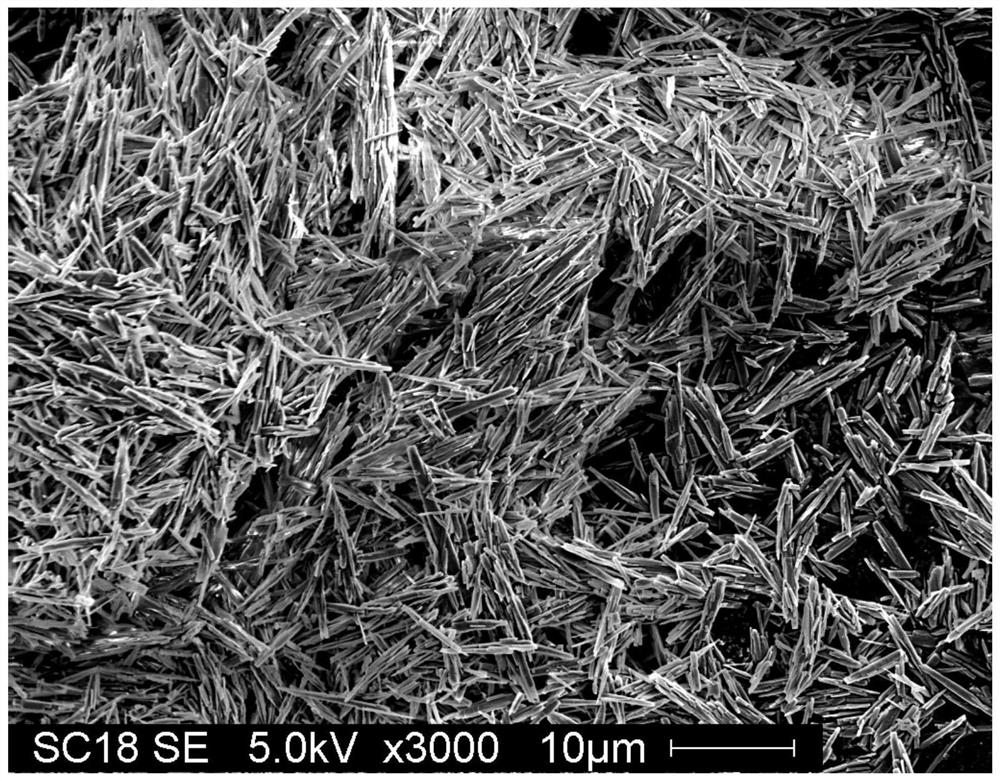

Embodiment 1

[0030] Add 2L of calcium chloride solution with a concentration of 3mol / L into the beaker, under the condition of a constant temperature water bath at 40°C, control the stirring speed at 200r / min, add 800ml of sulfuric acid with a concentration of 6M into the beaker within 2h, and equilibrate for 2h after the reaction. Calcium sulfate dihydrate can be obtained by filtration.

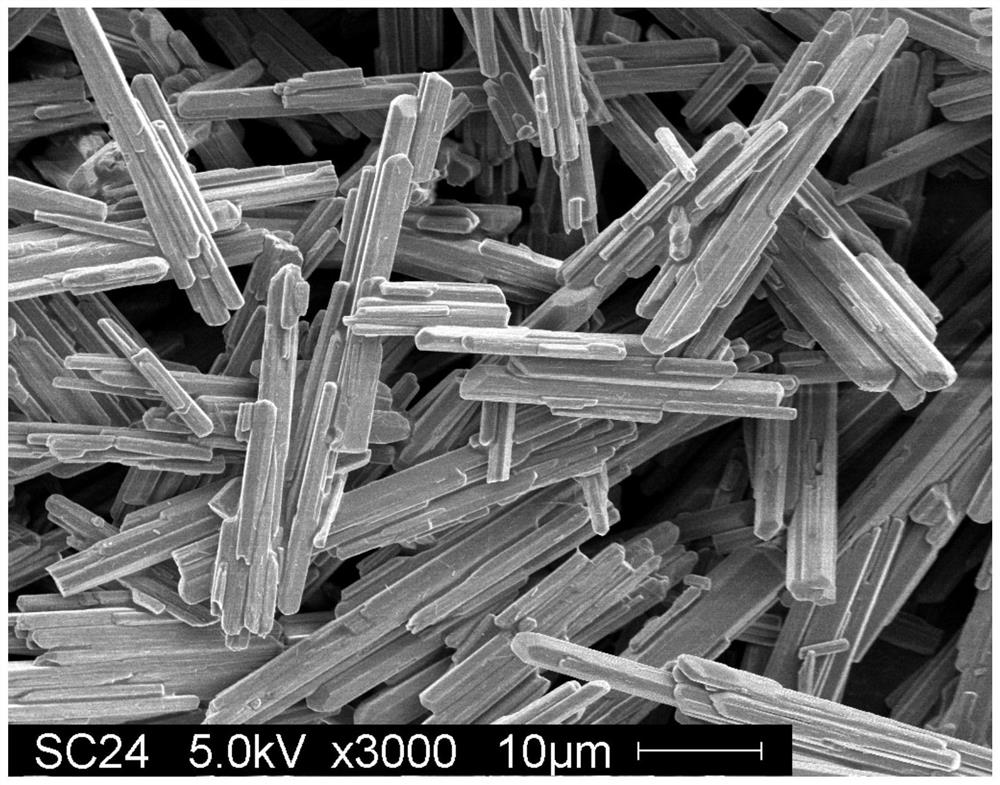

Embodiment 2

[0032] Add 2L of calcium chloride solution with a concentration of 3mol / L into the beaker, under the condition of a constant temperature water bath at 70°C, control the stirring speed at 200r / min, add 700ml of sulfuric acid with a concentration of 6M into the beaker within 2h, and equilibrate for 2h after the reaction. Filter to get calcium sulfate hemihydrate.

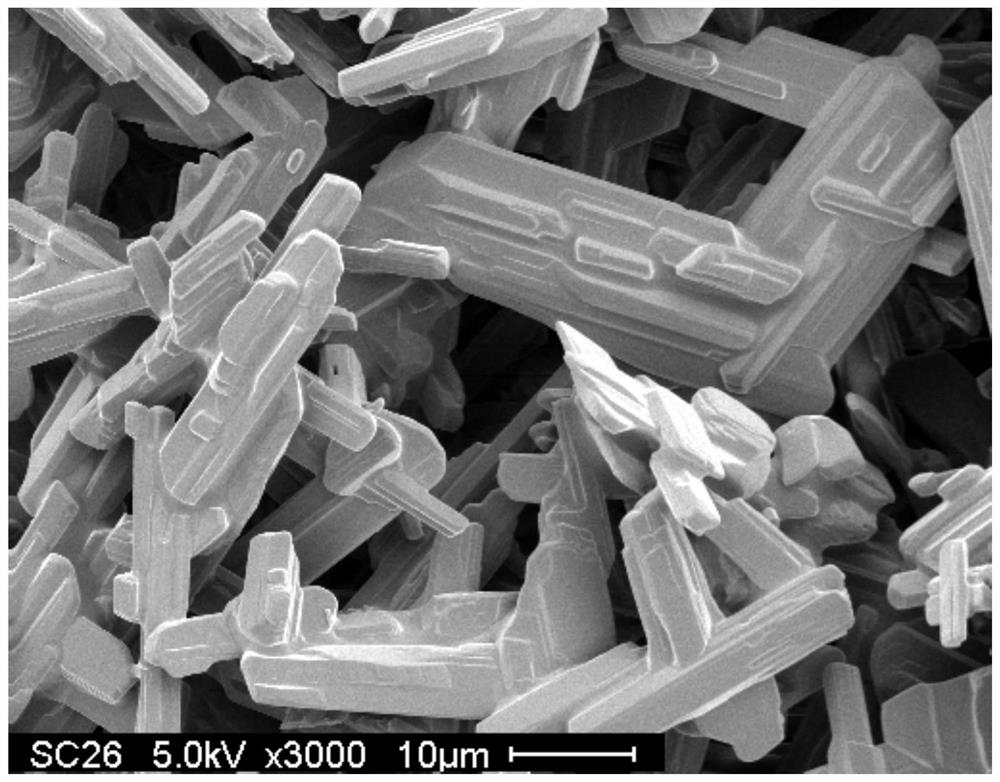

Embodiment 3

[0034] Add 2L of calcium chloride solution with a concentration of 3mol / L into the beaker, under the condition of a constant temperature water bath at 80°C, control the stirring speed at 200r / min, add 900ml of sulfuric acid with a concentration of 6M into the beaker within 2h, and equilibrate for 6h after the reaction. Filter to get anhydrous calcium sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com