A copper-based alloy powder material and its preparation method and application, cladding layer and its preparation method

A technology of powder materials and copper-based alloys, applied in metal material coating technology, metal processing equipment, coatings, etc., can solve problems such as poor corrosion resistance, achieve high corrosion resistance, achieve protection, and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

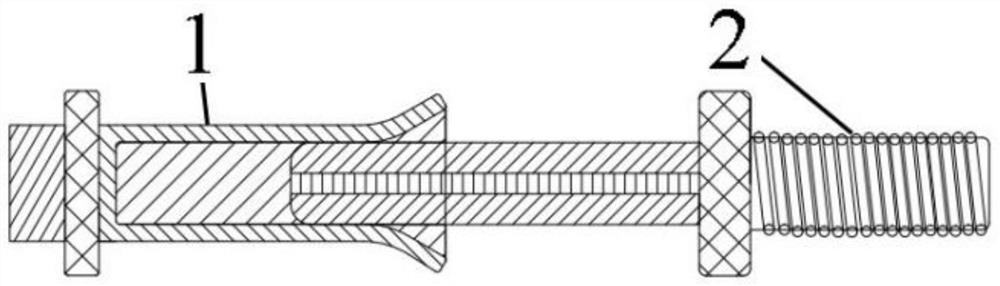

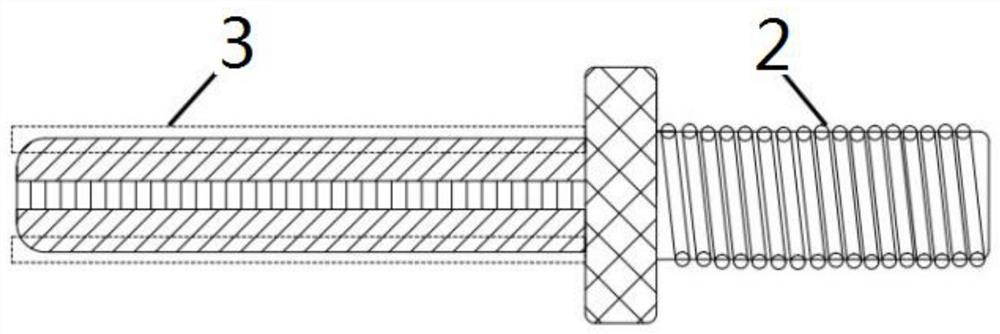

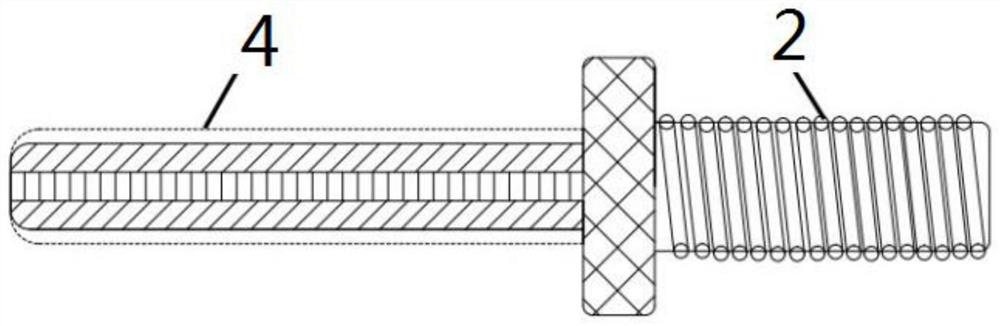

Image

Examples

preparation example Construction

[0049] In the present invention, the preparation method of the copper-based alloy powder material preferably includes the following steps: mixing Cu-Ni-Mo alloy powder, Ta powder and W powder to obtain a copper-based alloy powder material.

[0050] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0051] In the present invention, the Cu-Ni-Mo alloy powder is preferably self-produced. In the present invention, the preparation method of the Cu-Ni-Mo alloy powder preferably includes the following steps: after melting Cu, Ni and Mo, atomizing powder is obtained to obtain Cu-Ni-Mo alloy powder. In the present invention, the purity of Cu is preferably ≥99.9%, the purity of Ni is preferably ≥99.9%, and the purity of Mo is preferably ≥99.9%. In the present invention, the smelting of Cu, Ni and Mo preferably includes heating Cu to melting and then adding Ni and Mo to completel...

Embodiment 1

[0074] (1) Preparation of Cu-Ni-Mo alloy powder

[0075] Cu-Ni-Mo alloy powder: Ni 5wt%, Mo 4wt% and balance Cu;

[0076] Put Cu (purity ≥ 99.9%) in a vacuum intermediate frequency induction furnace for heating, and add Ni (purity ≥ 99.9%) and Mo (purity ≥ 99.9%) after Cu is completely melted, and when Cu, Ni and Mo are completely melted, heat at 1100 Heat preservation and smelting at ℃ for 50 minutes to obtain a smelted alloy liquid; place the smelted alloy liquid in the crucible of an atomization rapid condensation device, use the atomization rapid condensation device to carry out atomization and pulverization, and then sieve to obtain a particle size of 140 ~325 mesh Cu-Ni-Mo alloy powder; wherein, the atomization medium for atomization pulverization is nitrogen, and the flow rate of smelting alloy liquid is 0.7kg / min.

[0077] (2) Preparation of copper-based alloy powder materials

[0078] Copper-based alloy powder material: Ta 20wt%, W 2wt% and balance Cu-Ni-Mo alloy po...

Embodiment 2

[0088] The cladding layer was prepared according to the method of Example 1, the difference from Example 1 was that the copper-based alloy powder material contained Ta30wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com