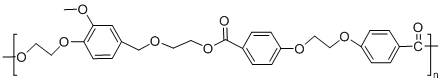

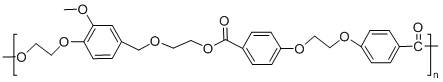

Polyester based on vanillyl alcohol derivative, preparation and application of polyester as pesticide slow-release agent

A technology of vanillyl alcohol and derivatives, applied in the field of polymer chemistry, can solve problems such as poor biocompatibility and biodegradability, pollution, threats to human life and health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

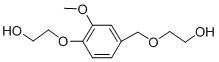

[0032] Synthesis of diol monomer M: Put 7.708g (0.05mol) of vanillyl alcohol and 1.382g (0.01mol) of potassium carbonate into the reaction vessel, add 100mL of N,N-dimethylformamide (DMF) to make it Dissolved, then added dropwise 8.052g (0.10mol) of 2-chloroethanol, stirred and reacted at 85°C for 4 hours, and cooled to room temperature after the reaction was completed. Then add 50mL (0.10mol / L) sodium hydroxide solution to it under stirring, precipitate white insoluble matter, filter, wash the filter cake twice with 200mL distilled water, and then dry the filter cake in an oven at 50°C for 1~2 hours , to obtain a diol monomer M that is , and the yield was 78.54%.

Embodiment 2

[0034] Into the dried one-necked flask, add 2.421g (0.01mol) of diol monomer M, 3.023g (0.010mol) of dibasic acid monomer ethylene glycol bis(4-carboxyphenyl) ether and 0.006 g of tetra-n-butylgermanium, protected by nitrogen, stirred at 170°C for 4 hours for esterification; then under high vacuum at a pressure of less than 5-15KPa, stirred for 3 hours for polycondensation at 240°C to obtain crude polyester. After cooling the polyester crude product under the protection of nitrogen, add 50mL chloroform, soak for 3 hours and then filter; take the clear solution and add it dropwise to a sufficient amount of methanol to obtain a turbid system, centrifuge to obtain a precipitate, wash the precipitate with methanol 3 times, and filter again The resulting solid was dried under vacuum at 70 °C for 2 hours to obtain 4.841 g of polyester P 1 , the number average molecular weight is 54500g / mol, and the yield is 86.73%.

[0035] Polyester P 1 For the preparation of microcapsules for wr...

Embodiment 3

[0037] Into the dried one-necked flask, add 2.421g (0.01mol) of dibasic alcohol monomer M, 3.325g (0.011mol) of dibasic acid monomer ethylene glycol bis(4-carboxyphenyl) ether and 0.006 g of dicarboxyethyl germanium trioxide, nitrogen protection, stirring at 150°C for esterification for 3 hours; then under high vacuum with a pressure of less than 5-15KPa, stirring at 220°C for 3 hours for polycondensation to obtain polyester Crude. After cooling the polyester crude product under the protection of nitrogen, add 50mL chloroform, soak for 2 hours and then filter; take the clear liquid and add it dropwise to a sufficient amount of methanol to obtain a turbid system, centrifuge to obtain a precipitate, wash the precipitate with methanol 3 times, and filter again The resulting solid was dried under vacuum at 65 °C for 3 hours to obtain 4.651 g of polyester P 2 , the number average molecular weight is 56800g / mol, and the yield is 88.52%.

[0038] Polyester P 2 For the preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com