Method for preparing 1,8-cineole derivative from 3-carene

A technology for eucalyptol and derivatives, which is applied in the field of preparing 1,8-cineole derivatives from 3-carene, can solve the problems of rare amine derivatives, and achieve abundant natural reserves, low price and high yield selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

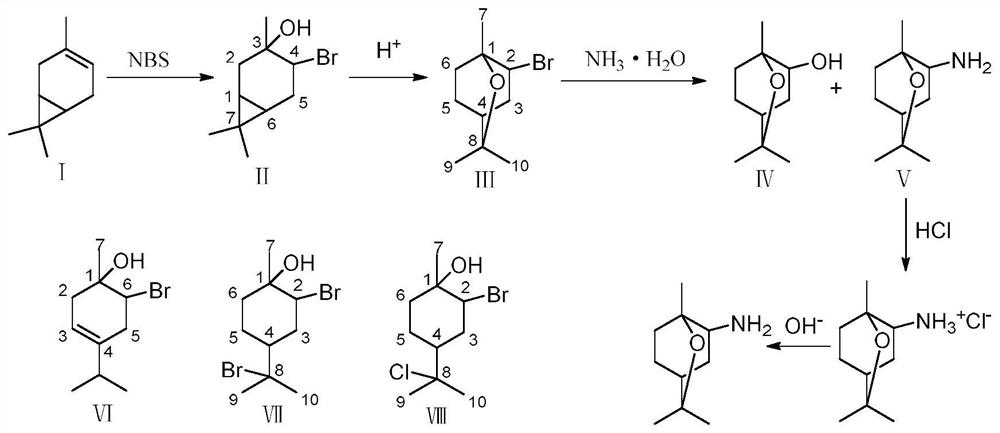

Method used

Image

Examples

Embodiment 1

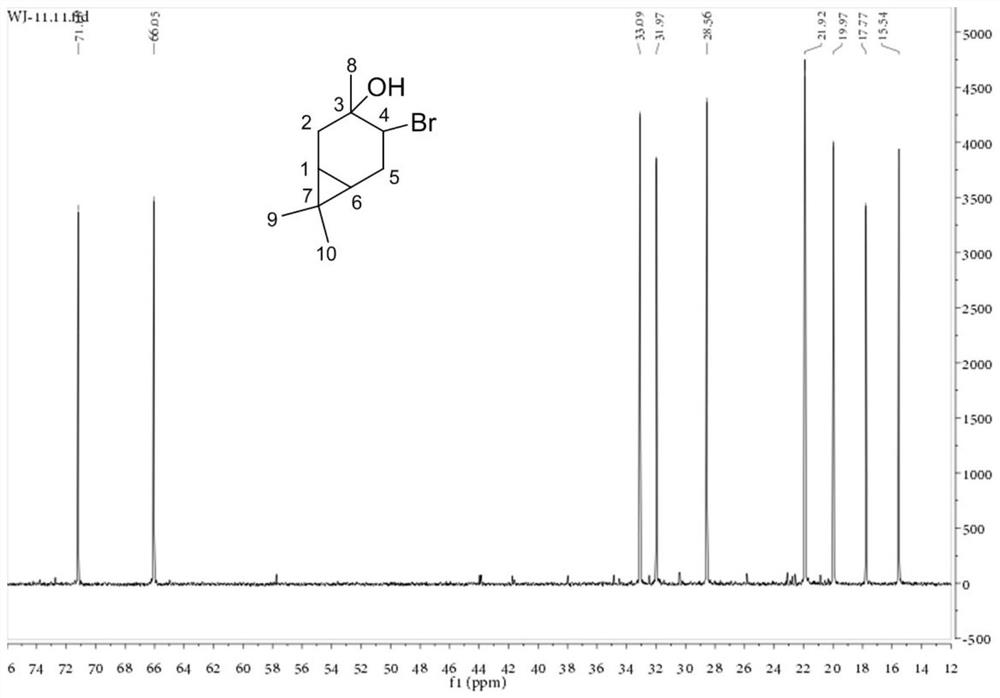

[0040] Example 1 Preparation of product A with 3-hydroxy-4-bromo-carbene as main component

[0041] 10.8g 3-carene, 8g CaCO 3 , 40 mL of water, 80 mL of 1,4-dioxane and 20 g of NBS were sequentially added to the reaction flask, and stirred at room temperature for 2 h; the reaction solution was transferred to 200 mL of water, filtered to remove the precipitate, and extracted with ethyl acetate (200 mL × 3 times), The aqueous layer was discarded; the organic layer was washed with 10% sodium thiosulfate-aqueous solution (200 mL×3 times), the aqueous layer was discarded, and the organic layer was dried by adding anhydrous sodium sulfate; the desiccant was removed by filtration, and the solvent was recovered by rotary evaporation to obtain the product A15.2g, wherein the GC content of compound II is 71.8%.

Embodiment 2

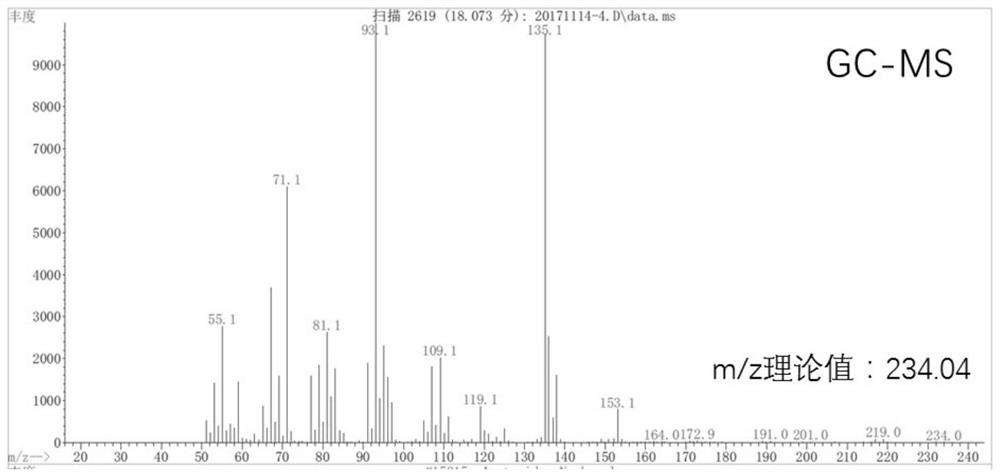

[0042] Example 2 Preparation of 2-bromo-1,8-cineole

[0043] Add 1 g of product A obtained in Example 1 and 5 mL of chloroform into the reaction flask, turn on and stir, add 0.94 g of trimethylbromosilane, and stir at 20°C for 1 h; the solvent is recovered by rotary evaporation to obtain product B, wherein compound III, The GC contents of compound VI and compound VII are: 42.95%, 16.18% and 13.14%, respectively.

Embodiment 3

[0044] Example 3 Preparation of 2-bromo-1,8-cineole

[0045] Add 1 g of product A obtained in Example 1 and 5 mL of chloroform into the reaction flask, turn on and stir, add 0.47 g of trimethylbromosilane, and stir at 20°C for 1 h; the solvent is recovered by rotary evaporation to obtain product B, wherein compound III, The GC contents of compound VI and compound VII are: 36.61%, 14.68% and 6.53%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com