Molten salt, electrochemical purification method of molten salt and electrochemical device

An electrochemical and molten salt technology, applied in chemical instruments and methods, fluoride preparation, chloride preparation, etc., can solve the problems of low efficiency of molten salt removal and purification, and achieve environmental protection reduction, emission reduction, and high deoxidation level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] High purity MgCl 2 - Preparation and purification of NaCl-KCl.

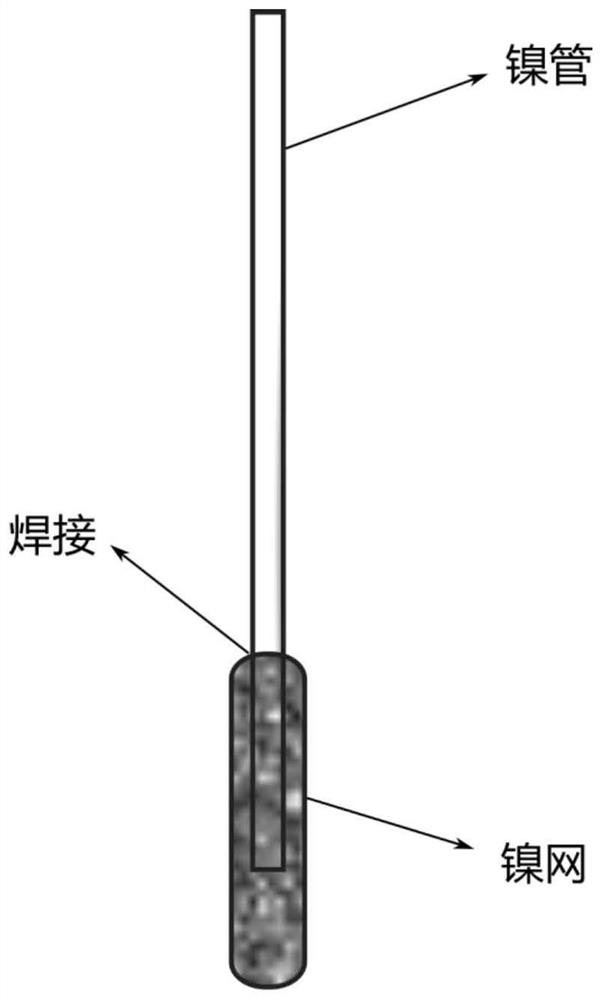

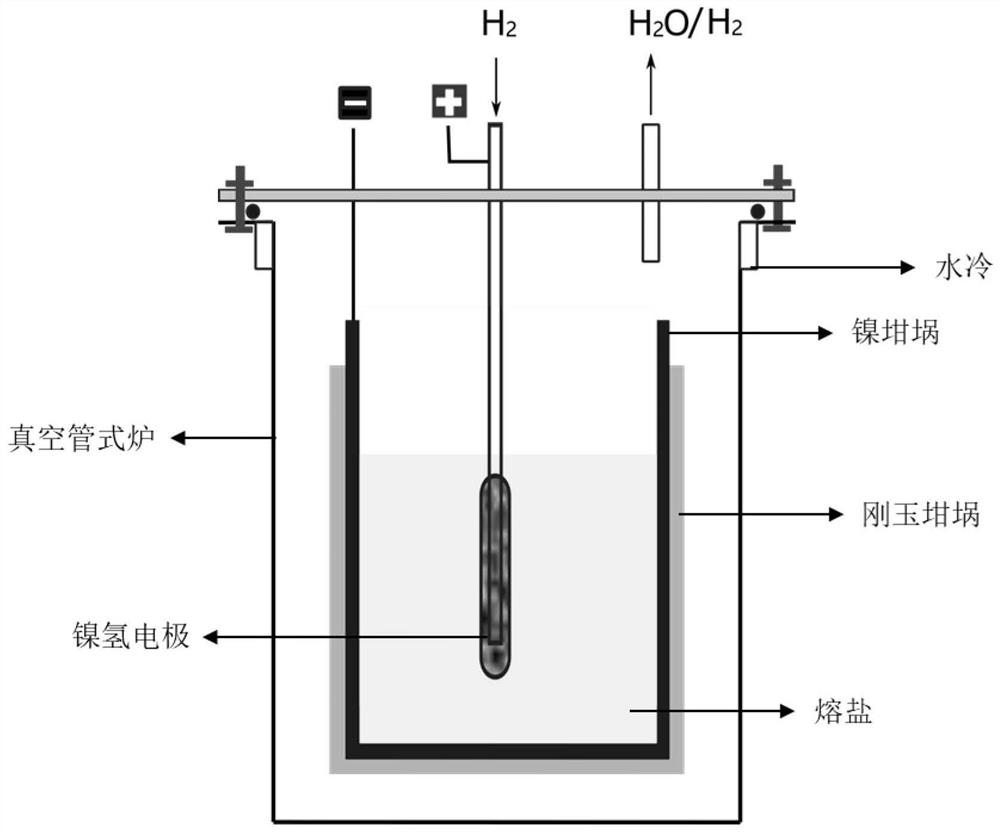

[0122] Weigh 275g MgCl respectively 2 , 123g NaCl, and 102g KCl were mixed evenly, placed in a nickel crucible with an inner diameter of 80mm and a height of 120mm, and heated to 600°C under an argon atmosphere to melt for later use. use image 3 The experimental setup shown was used for electrochemical tests and electrolytic purification experiments. Among them, the Ni-MH electrode is welded with a nickel tube with an outer diameter of 6mm and an inner diameter of 3.5mm and a nickel mesh with a mesh size of 1mm×2mm (such as figure 1 shown), the total surface area of the nickel tube and the nickel mesh immersed in the molten salt is about 12.5cm 2 . The purity of all nickel materials (including nickel crucible, nickel tube, nickel mesh) is ≥99.5%. Hydrogen purity ≥99.99%. In the electrochemical test, the working electrode (WE) is a nickel hydrogen electrode, the counter electrode (CE) is a nickel ...

Embodiment 2

[0141] Preparation and purification of high-purity LiF-NaF-KF.

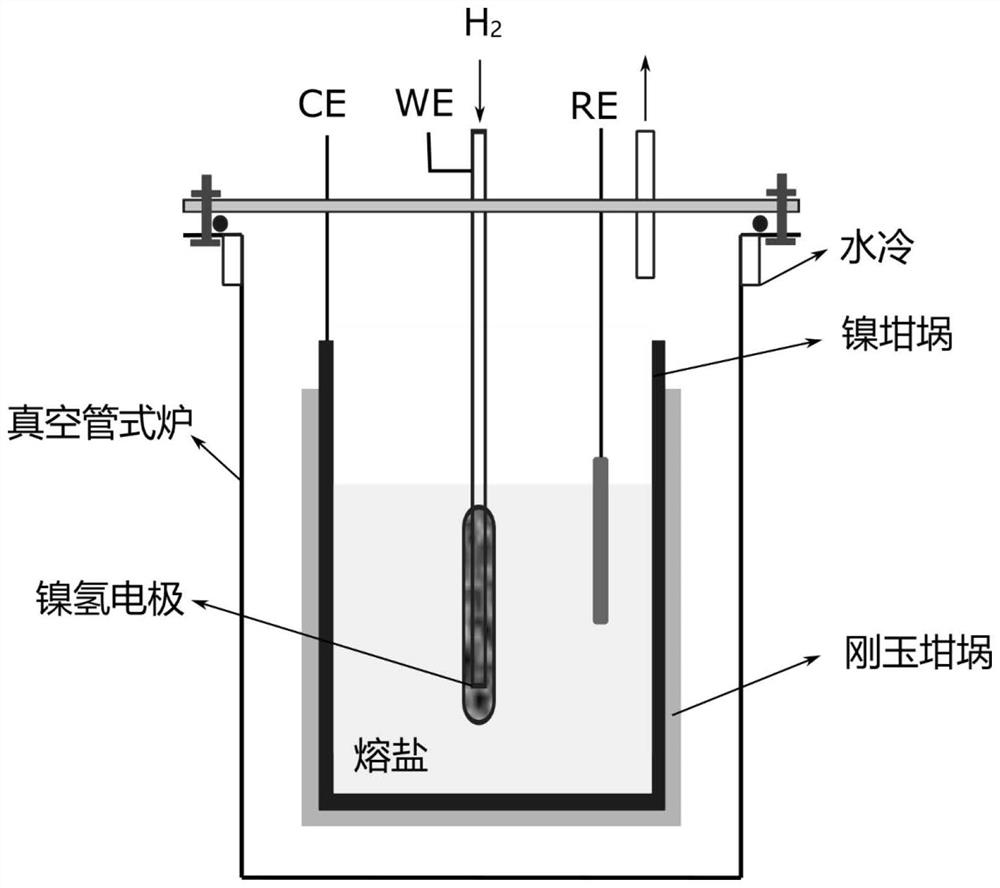

[0142] Weigh 146.5g LiF, 58.5g NaF, and 295.0g KF, mix them evenly, place them in a nickel crucible with an inner diameter of 80mm and a height of 120mm, and heat up to 650°C under an argon atmosphere to melt for later use. use figure 2 The experimental setup shown is for electrolytic purification experiments. Among them, the Ni-MH electrode is welded by a nickel tube with an outer diameter of 6mm and an inner diameter of 3.5mm and a nickel mesh with a mesh size of 1mm×2mm. The total surface area of the nickel tube and nickel mesh immersed in molten salt is about 16.2cm 2 . The purity of all nickel materials (including nickel crucible, nickel tube, nickel mesh) is ≥99.5%. Hydrogen purity ≥99.99%. The Ni-MH electrode flow is constant at 200mL / min, and the electrolysis mode is a constant current of 15mA. Purify by electrolysis of 2 hours, the oxygen content in the molten salt before and after sampling analy...

Embodiment 3

[0161] High-purity LiF-BeF 2 -ZrF 4 preparation and purification.

[0162] High-purity LiF-BeF 2 -ZrF 4 preparation and purification. Weigh 214.7g LiF and 179.1g BeF respectively 2 , 106.2gZrF 4 After mixing evenly, place it in a nickel crucible with an inner diameter of 80mm and a height of 120mm, and heat it up to 600°C under an argon atmosphere to melt it for later use. use figure 2 The experimental setup shown is for electrolytic purification experiments. Among them, the Ni-MH electrode is welded by a nickel tube with an outer diameter of 6mm and an inner diameter of 3.5mm and a nickel mesh with a mesh size of 1mm×2mm. The total surface area of the nickel tube and nickel mesh immersed in molten salt is about 18.5cm 2 . The purity of all nickel materials (including nickel crucible, nickel tube, nickel mesh) is ≥99.9%. Hydrogen purity ≥ 99.995%. The Ni-MH electrode flow rate is constant at 200mL / min, and the electrolysis mode is constant voltage 1.1V. Purify b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| total surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com