Method for pyrolyzing, recycling and granulating waste refrigerator plastic

A technology for plastics and refrigerators, which is applied in the field of pyrolysis recycling of waste refrigerator plastics to make granules. It can solve the problems that are not easy to separate, the formed granules stick together, affect the integrity and aesthetics of the final molded parts, and achieve the overall characteristics. Complete, fully responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

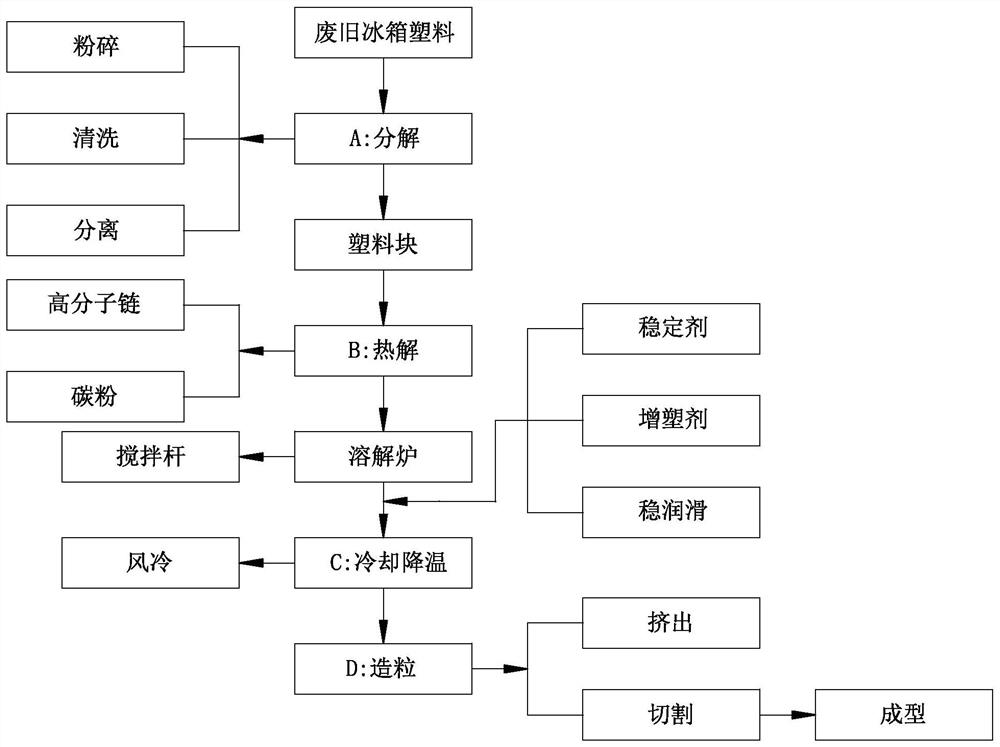

[0037] I: First, decompose the plastic of the waste refrigerator, crush it first, and separate the high-density impurities in it from the plastic block through cleaning, and complete the first step of decomposition;

[0038] II: Pyrolysis the processed plastic block, then put the plastic block into the melting furnace for high temperature treatment, melt the plastic block, add stabilizer barium isozincate, Plasticizer chlorinated paraffin and lubricant barium stearate, and the mixture produced by them is stirred and mixed through the stirring rod in the dissolving furnace, so that the substances in the dissolving furnace can react more completely;

[0039] III: Cool the mixture after mixing, and cool the mixture to a certain extent by air-cooling to ensure that it will not be too diluted or too hard, which is convenient for subsequent granulation;

[0040] IV: The mixture falls into the interior of the granulator, and the mixture is dry-pressed through the mold, and then the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com