High-concentration phenol-containing wastewater precipitation method phenol removal and recovery method

A recovery method and technology for phenol wastewater, applied in chemical instruments and methods, water pollutants, multi-stage water treatment, etc., can solve the problems of heavy metal pollution, high operating cost, long process flow, etc., and achieve low discharge concentration and equipment structure. Simple, technically stable and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

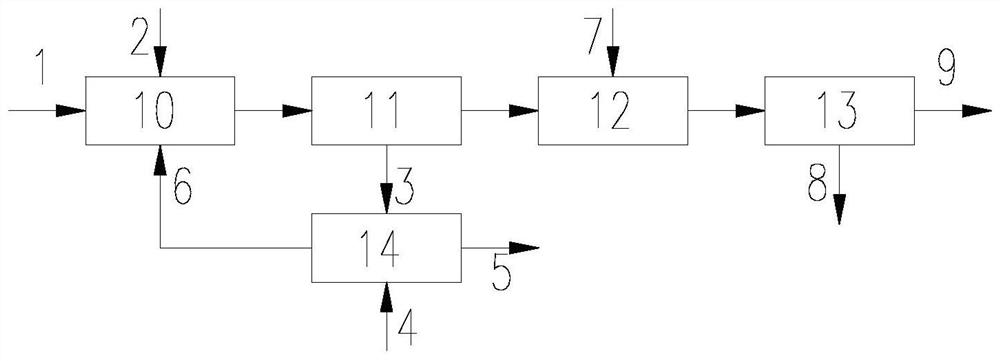

Method used

Image

Examples

Embodiment 1

[0030] Applying the above-mentioned device for treating high-concentration phenol-containing wastewater, after degreasing and deacidifying the wastewater of a coal gasification project, the total phenol content in the wastewater is 5000mg / L, and the Ba of the primary precipitation reaction is 2+ ions using BaCl 2 , HCl is used for the acidification of barium phenolate, the pH value of the first-order precipitation reaction is controlled to 9.1, and NaOH is selected as the pH regulator. After the first-order precipitation reaction, the recovery rate of phenol reaches 88%, the residual phenol concentration in the wastewater is 600mg / L, and the COD concentration is 3000mg / L L, to meet the water intake requirements of the subsequent biochemical treatment section. Residual Ba in wastewater after primary precipitation reaction 2+ The ion concentration is 2100mg / L, the Ba of the secondary precipitation reaction 2+ The ion precipitant uses Na 2 SO 4 , control the pH value of the s...

Embodiment 2

[0032] Using the above-mentioned device for treating high-concentration phenol-containing wastewater, after the wastewater of a coking project is deoiled, deacidified and deaminated, the total phenol content in the wastewater is 9000mg / L, and the Ba of the primary precipitation reaction is 2+ ions using BaCl 2 , HCl is used for the acidification of barium phenolate, the pH value of the primary precipitation reaction is controlled to 9.8, and NaOH is selected as the pH regulator. After the primary precipitation reaction, the recovery rate of phenol reaches 90%, the residual phenol concentration in the wastewater is 900mg / L, and the COD concentration is 4500mg / L L, to meet the water intake requirements of the subsequent biochemical treatment section. Residual Ba in wastewater after primary precipitation reaction 2+ The ion concentration is 2000mg / L, the Ba of the secondary precipitation reaction 2+ The ion precipitant uses Na 2 SO 4 , the pH value of the secondary precipitat...

Embodiment 3

[0034] Using the above-mentioned device for treating high-concentration phenol-containing wastewater, after degreasing and deacidifying the wastewater of a semi-coke project, the total phenol content in the wastewater is 15000mg / L, and the Ba of the primary precipitation reaction 2+ ions using BaCl 2 2H 2 0, HCl is used for barium phenol hydrochloride, and the pH value of the primary precipitation reaction is controlled to 11. NaOH is used as the pH regulator. After the primary precipitation reaction, the recovery rate of phenol reaches 94.7%, the residual phenol concentration in the wastewater is 800mg / L, and the COD concentration is 4000mg / L, to meet the water intake requirements of the subsequent biochemical treatment section. Residual Ba in wastewater after primary precipitation reaction 2+ The ion concentration is 2000mg / L, the Ba of the secondary precipitation reaction 2+ The ion precipitant uses Na 2 SO 4 , the pH value of the secondary precipitation reaction is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com