Casting method for refining structure of investment casting

A casting and investment technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of coarse structure and low mechanical properties of castings, and achieve obvious effects, avoid loosening, and shorten the production cycle of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

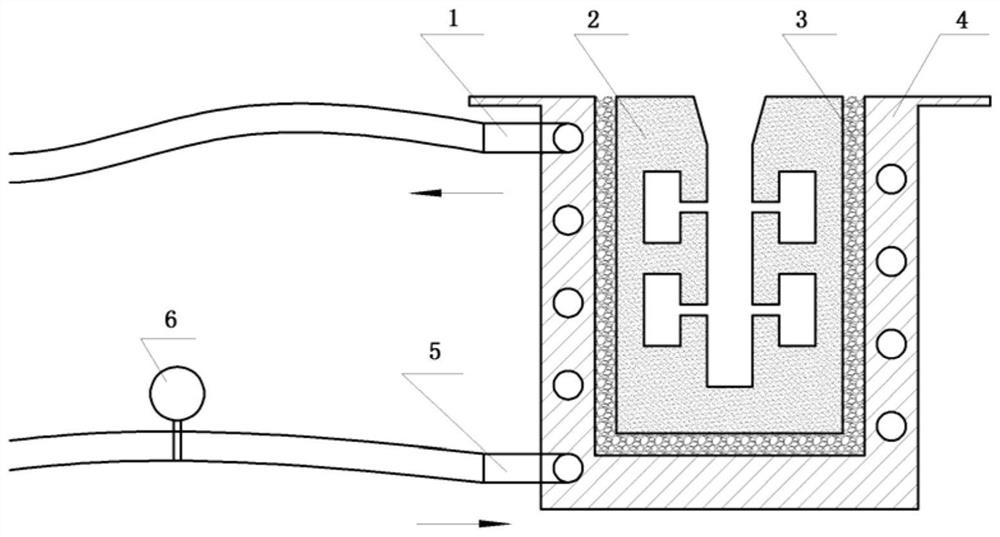

[0035] Taking an investment precision aluminum alloy casting as an example, the grade is ZL107, which specifically includes the following steps:

[0036] S1, prepare the molten mold shell 2 according to the process requirements;

[0037] S2. Heating the molten shell 2 to the preheating temperature and keeping it warm according to the process requirements;

[0038] S3. First cover the bottom of the water-cooled copper mold 4 with quartz sand 3 with a thickness of 30 mm. After the molten mold shell 2 is transferred to the water-cooled copper mold 4, use quartz sand 3 to cover the gap between the molten mold shell 2 and the water-cooled copper mold 4. The gap between them is filled tightly, and the diameter of the cooling water channel of the spiral structure inside the water-cooled copper mold 4 is 15mm;

[0039] S4. Pouring the melted ZL107 aluminum alloy liquid into the molten mold shell 2 according to the process requirements;

[0040] S5. Turn on the switch of the water in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com