Method for conducting negative pressure casting on casting product through light-curing rapid prototyping lost foam

A negative pressure casting and lost foam technology, applied in casting molding equipment, cores, molds, etc., can solve the problems of large thermal expansion coefficient, shell cracking, shell expansion cracking, etc., to achieve fast drying speed, cost saving, Guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

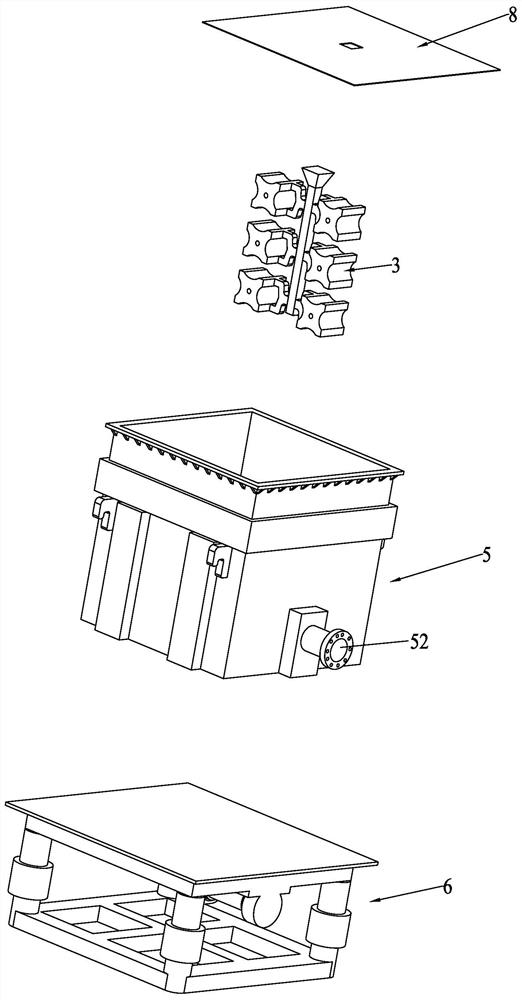

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] A method of using light-cured rapid prototyping lost foam for negative pressure casting casting products, including the following processes:

[0041] Step 1: Light curing rapid prototyping lost foam 1 treatment

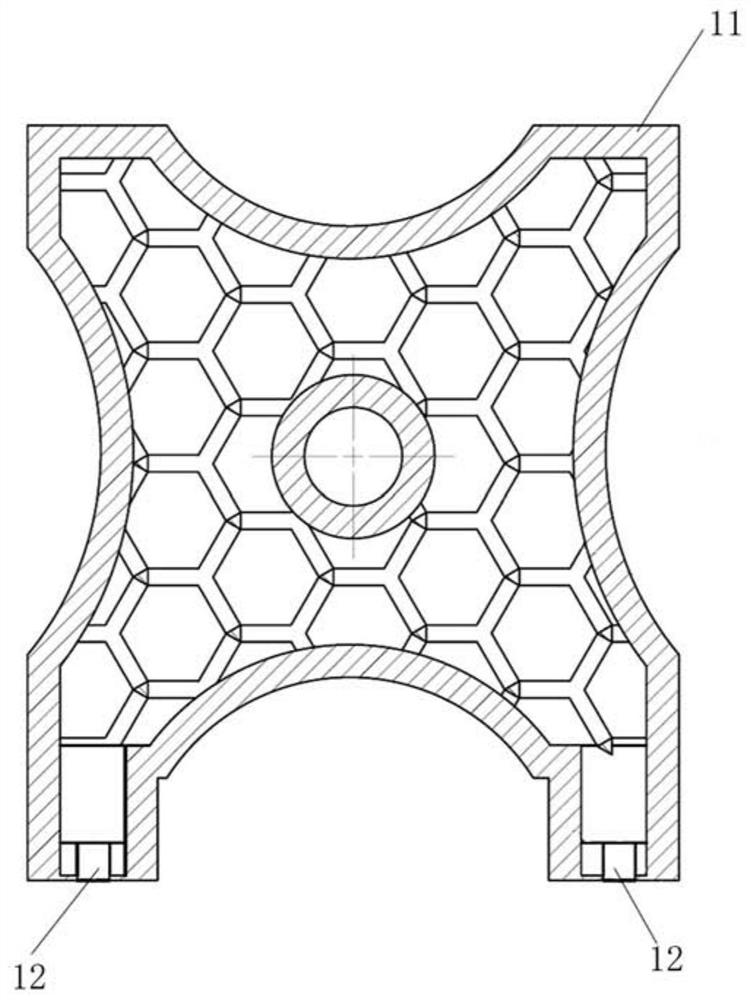

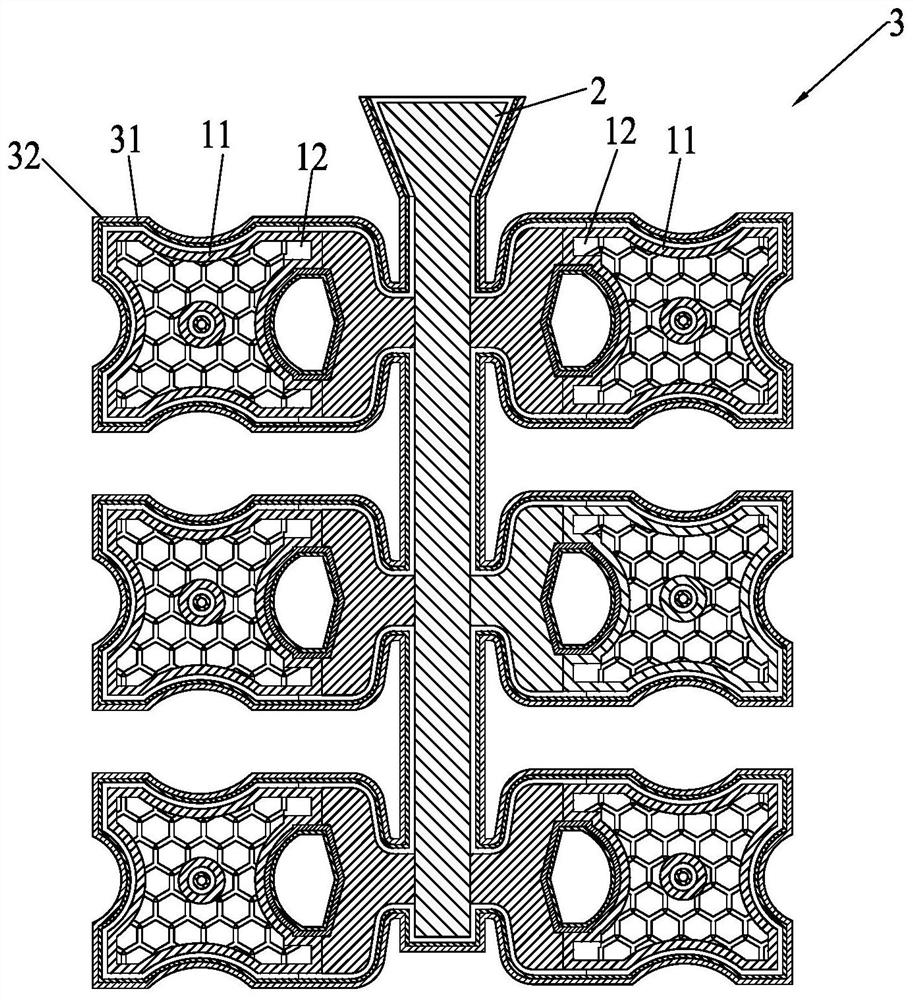

[0042] 1. For the 3D model designed by modeling software, use slicing software or model processing software to shell the model, keep the wall thickness of the shell model 0.8mm ~ 1.0mm, shell 11 converges inward, and the accuracy is not less than 1.0 mm;

[0043] 2. For the model that has been shelled, the internal reinforcement structure is modeled. The internal support structure adopts the tetrahedral support foot method, the foot length is 10mm, and the foot thickness is 3mm.

[0044] 3. Set a drain hole 12 at the low position of the shell model, and the diameter of the drain hole 12 is between 2 and 5 mm to ensure that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com