Preparation method of micro-nano metal particle surface coating

A metal particle, micro-nano technology, applied in the field of surface engineering, can solve the problems of growing on the cathode and difficult to form a coating, etc., achieve high material utilization rate, good performance at high temperature, and improve connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Specific embodiment one: what this embodiment records is a kind of preparation method of micronano metal particle surface coating, and the specific steps of described method are as follows:

[0030] Step 1: Select the micro-nano metal particles to be electroplated, and remove the oxide film on their surface;

[0031] Step 2: Select and configure the plating solution to be electroplated, select and make the electrode for electroplating;

[0032] Step 3: Mixing the micro-nano metal particles obtained in step 1 with the plating solution in step 1 to prevent the micro-nano metal particles from being oxidized in the air;

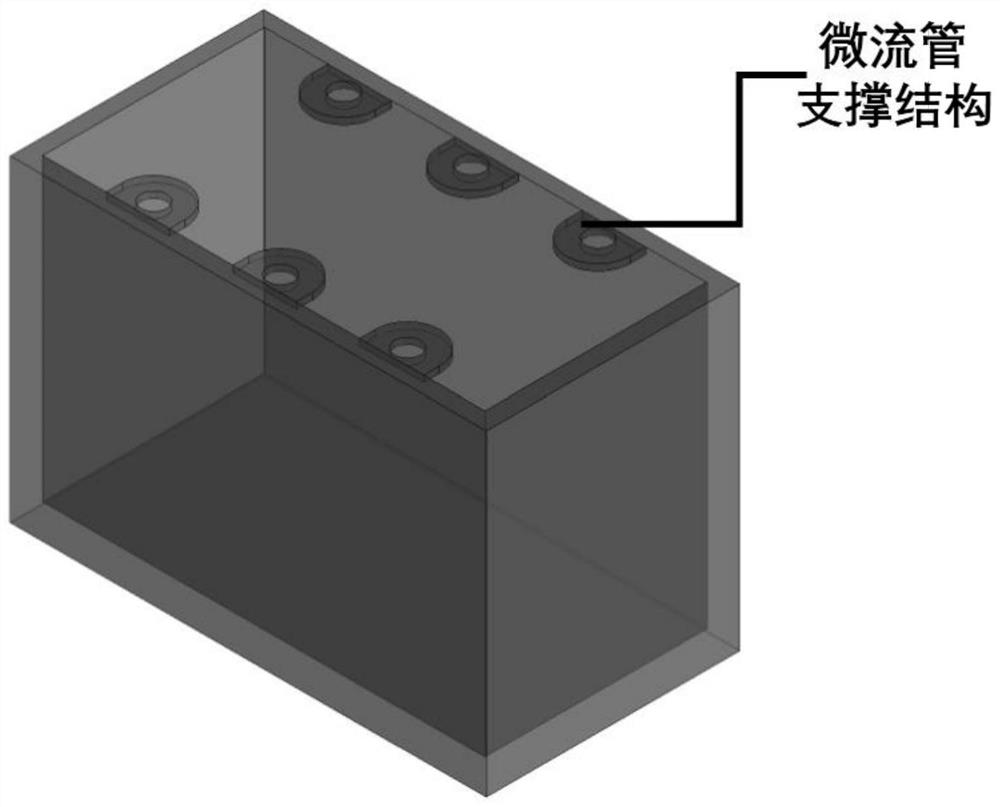

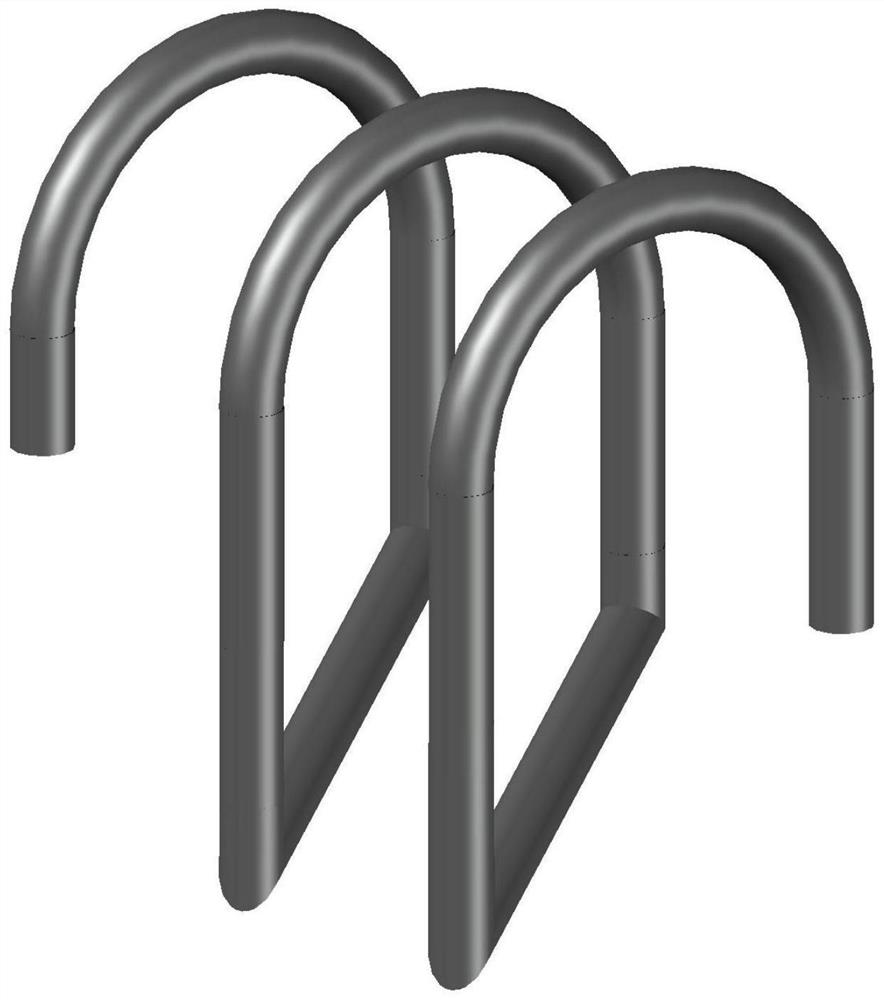

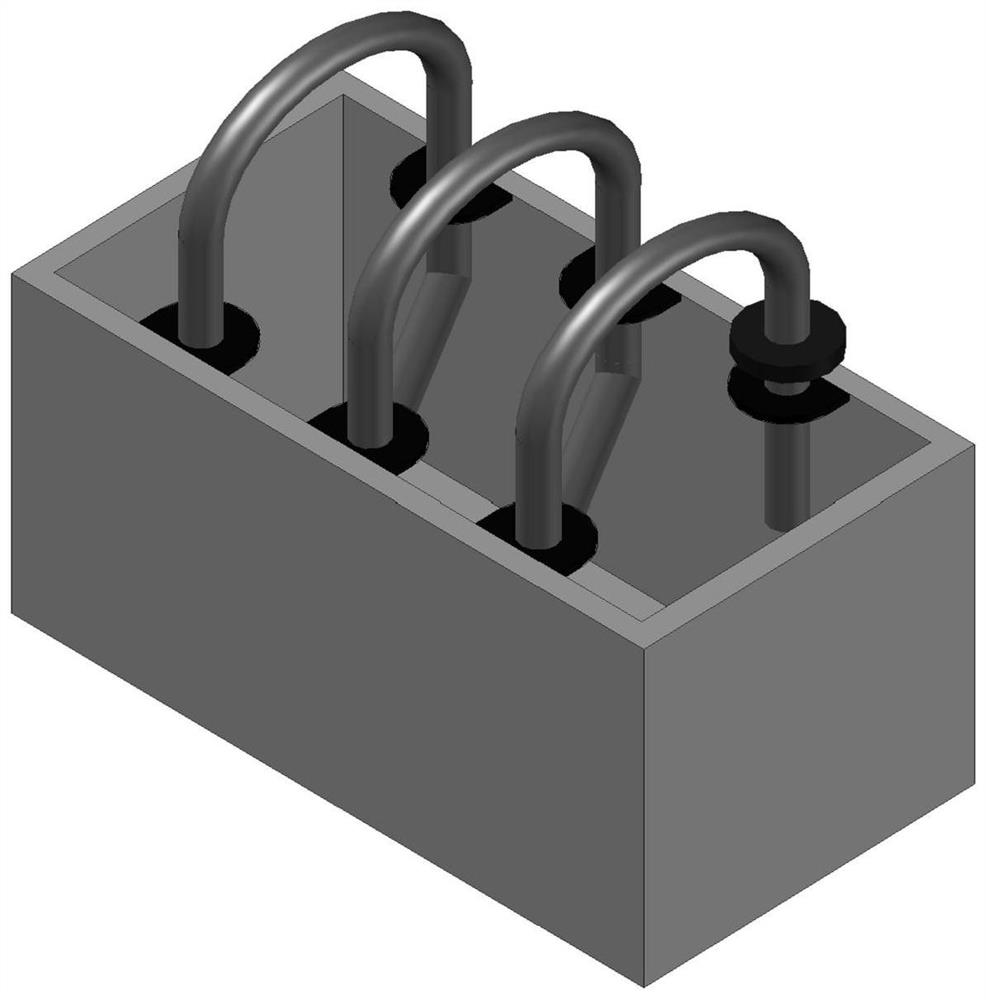

[0033] Step 4: Assembling the electroplating device, the electroplating device specifically includes an electroplating tank, a micro-flow tube, a micro-pump and a power supply; the micro-flow tube includes a vertical section and a transition section, such as figure 2 Shown; Described vertical section arranges many pairs of electroplating electrodes and t...

specific Embodiment approach 2

[0042] Embodiment 2: The method for preparing a coating on the surface of micro-nano metal particles described in Embodiment 1, in step 1, the micro-nano metal particles to be electroplated are spherical particles with a diameter of 50 nm to 10 μm, and the material is Copper and other micro-nano metal particles with good electrical conductivity.

specific Embodiment approach 3

[0043] Embodiment 3: In the method for preparing a coating on the surface of micro-nano metal particles described in Embodiment 1, in the circulation process of the plating solution, it is necessary to ensure that the plating solution remains in a continuous state without bubbles in the micro-flow tube.

[0044] Specific embodiment four: the preparation method of a kind of micro-nano metal particle surface coating described in specific embodiment one, in step eight, the flow velocity of plating solution in the micro-flow tube is 0.1m / s, and this flow rate makes in electroplating process, micro The nano metal particles stay in the cathode for a short time to complete the electroplating, and due to the scouring of the water flow, the micro and nano metal particles will not grow on the surface of the cathode and enter the plating solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com