Preparation method of monatomic metal-nitrogen doped carbon aerogel electrocatalyst

A carbon aerogel and electrocatalyst technology, which is applied to electrodes, circuits, electrolytic components, etc., can solve the problems of uneven distribution of iron, low activity, low electrocatalytic activity, etc., avoiding the pickling step, simple preparation method, Porous structure with high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

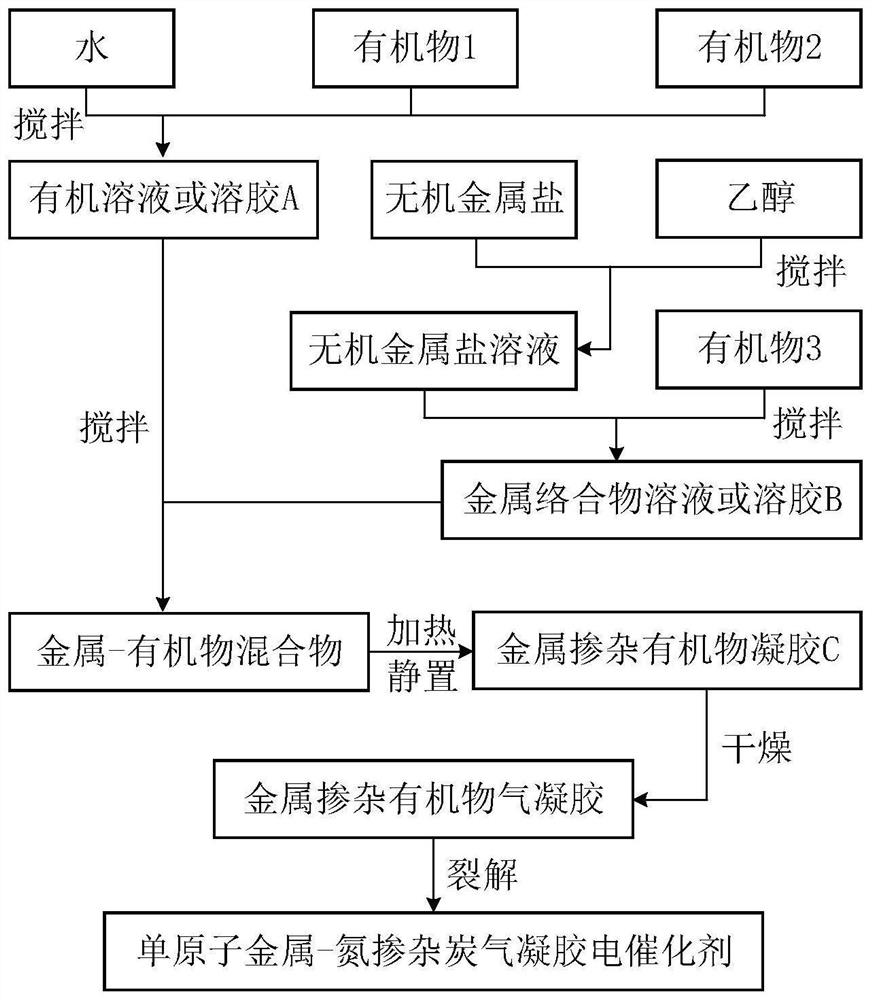

[0047] Such as figure 1 Shown, adopt the present invention to prepare embodiment 1 to comprise the following steps:

[0048] The first step, prepare organic solution or sol A, choose 1mol resorcinol ( figure 1 Organic matter in 2) and 2mol formaldehyde ( figure 1 The organic matter 1) in the solution was dissolved in 60mol deionized water and stirred until completely dissolved to form a uniform organic solution or sol A.

[0049] Second step, prepare metal complex solution or sol B, the iron chloride hexahydrate of 1 / 25mol ( figure 1 Inorganic metal salt in), be dissolved in dehydrated alcohol whose molar mass is 10 times, stir until completely dissolving, form ferric chloride inorganic salt solution ( figure 1 Inorganic metal salt solution). Select the epoxy chlorohydrin ( figure 1 The organic matter in 3) joins in the inorganic metal salt solution, continues to stir until the solution is clarified, prepares ferric chloride sol B ( figure 1 Metal complex solutions or so...

preparation Embodiment 2

[0057] Such as figure 1 Shown, adopt the present invention to prepare embodiment 2, comprise the following steps:

[0058] The first step, prepare organic solution or sol A, choose 1mol resorcinol (figure 1 Organic matter in 2) and 2mol formaldehyde ( figure 1 The organic matter 1) in the solution was dissolved in 60mol deionized water and stirred until completely dissolved to form a uniform organic solution or sol A.

[0059] Second step, prepare metal complex solution or sol B, the cobalt chloride hexahydrate of 1 / 25mol ( figure 1 Inorganic metal salt in), be dissolved in the dehydrated alcohol whose molar mass is 12 times, stir until completely dissolving, form the cobalt chloride inorganic salt solution ( figure 1 Inorganic metal salt solution). Choose epichlorohydrin whose molar mass is 8 times of the molar mass of cobalt chloride hexahydrate to join in the inorganic metal salt solution, continue to stir until the solution is clear, and prepare cobalt chloride sol B ( ...

Embodiment 2

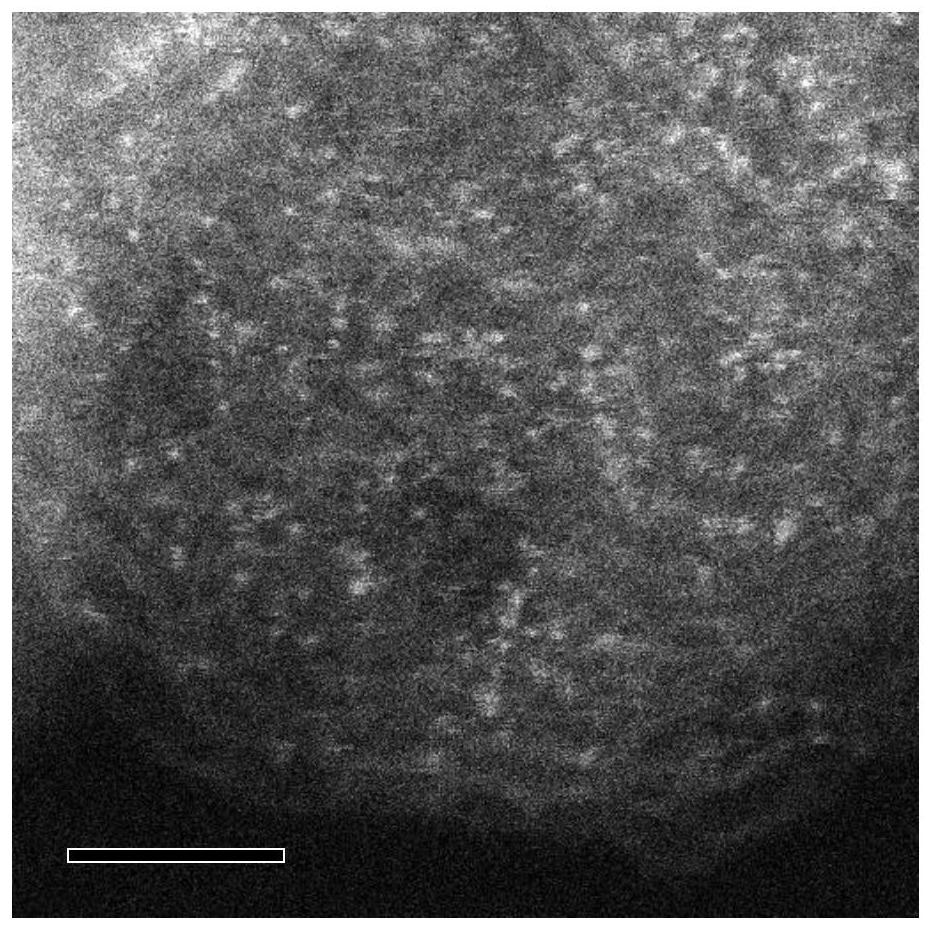

[0065] The single-atom cobalt-nitrogen-doped carbon airgel electrocatalyst prepared in Example 2 has a very high catalytic oxygen evolution reaction activity, in 0.1mol / L potassium hydroxide solution, 10mA / cm 2 The corresponding potential is 1.635V vs RHE, and the half-wave potential difference with the oxygen reduction reaction is 0.710V. Figure 4 It is a spherical aberration transmission electron microscope photo of Example 2. The scale at the bottom of the electron microscope shows 2nm. The bright spot in the figure is the cobalt active site. The scale of the cobalt active site is much smaller than 1nm. It can be seen that it has an active catalytic site on a single-atom scale, and the utilization efficiency of cobalt is very high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com