High-strength composite electric power tube and preparation process thereof

A preparation process and technology for power pipes, which are used in tubular articles, other household appliances, applications, etc., can solve the problems of uneven distribution, low bending resistance of pipes, and poor compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Modified carbon nanotubes are made by the following steps:

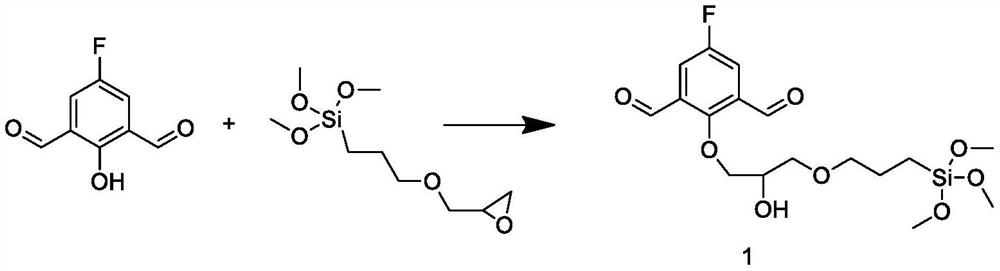

[0036] Step A1. Add 0.1mol 4-fluoro-2,5-dialdehyde phenol, 0.1mol coupling agent KH-560 and 100mL dimethyl sulfoxide into a three-necked flask, control the temperature at 50°C, stir for 10 minutes, and then add Potassium hydroxide, the stirring speed is 120r / min, reflux reaction for 3h, after the reaction is finished, filter, add deionized water to the filtrate to wash, then extract with ethyl acetate, rotary steam, to obtain intermediate 1, the consumption of potassium hydroxide is 6% of the total mass of 4-fluoro-2,5-dialdehyde phenol and coupling agent KH-560;

[0037] Step A2: Add 0.1 mol of intermediate 1 and 68.5 mL of 1,4-dioxane into a three-necked flask, stir at room temperature for 3 minutes, then dropwise add 0.2 mol of 4-amino-1,2,2,6, 6-pentamethylpiperidine, reflux reaction for 24 hours, after the reaction, 1,4-dioxane was removed by rotary evaporation to obtain intermediate 1;

[0038] Step A3: ...

Embodiment 2

[0041] Modified carbon nanotubes are made by the following steps:

[0042] Step A1. Add 0.1mol 4-fluoro-2,5-dialdehyde phenol, 0.1mol coupling agent KH-560 and 110mL dimethyl sulfoxide into a three-necked flask, control the temperature at 55°C, stir for 10 minutes, and then add Potassium hydroxide, the stirring speed is 140r / min, reflux reaction 4h, after the reaction is finished, filter, add deionized water to wash in the filtrate, then extract with ethyl acetate, rotary steam, obtain intermediate 1, the consumption of potassium hydroxide is 7% of the total mass of 4-fluoro-2,5-dialdehyde phenol and coupling agent KH-560;

[0043] Step A2: Add 0.1 mol of intermediate 1 and 69.2 mL of 1,4-dioxane into a three-necked flask, stir at room temperature for 3 minutes, then dropwise add 0.2 mol of 4-amino-1,2,2,6, 6-pentamethylpiperidine, reflux reaction for 24 hours, after the reaction, 1,4-dioxane was removed by rotary evaporation to obtain intermediate 1;

[0044] Step A3. Add 0...

Embodiment 3

[0047] Modified carbon nanotubes are made by the following steps:

[0048] Step A1. Add 0.1mol 4-fluoro-2,5-dialdehyde phenol, 0.1mol coupling agent KH-560 and 120mL dimethyl sulfoxide into a three-necked flask, control the temperature at 60°C, stir for 10 minutes, and then add Potassium hydroxide, the stirring speed is 150r / min, reflux reaction 5h, after the reaction is finished, filter, add deionized water to wash in the filtrate, then extract with ethyl acetate, rotary steam, obtain intermediate 1, the consumption of potassium hydroxide is 8% of the total mass of 4-fluoro-2,5-dialdehyde phenol and coupling agent KH-560;

[0049] Step A2: Add 0.1 mol of intermediate 1 and 74.2 mL of 1,4-dioxane into a three-necked flask, stir at room temperature for 3 minutes, then dropwise add 0.2 mol of 4-amino-1,2,2,6, 6-pentamethylpiperidine, reflux reaction for 24 hours, after the reaction, 1,4-dioxane was removed by rotary evaporation to obtain intermediate 1;

[0050] Step A3, add 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com