Sulfur-coated compound fertilizer for garlic and preparation method thereof

A technology of sulfur coating and compound fertilizer, which is applied in the field of garlic sulfur coating compound fertilizer and its preparation, can solve problems such as high labor cost, impact on garlic yield and quality, and soil health threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Slow-release insecticides are made by:

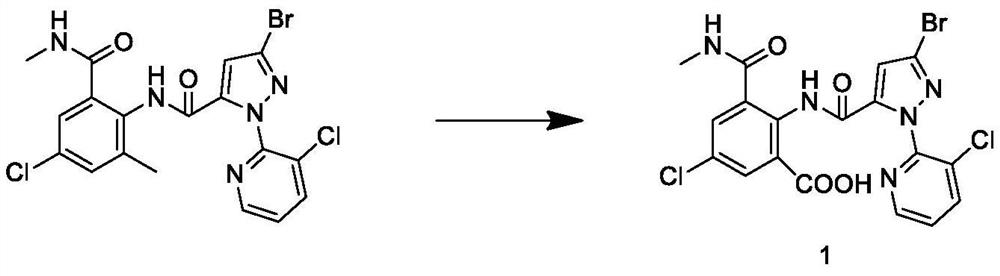

[0028] Step S11, add 0.8g of chlorantraniliprole and 25mL of DMF into the reaction kettle, add 0.1g of potassium permanganate and 3mL of hydrochloric acid solution with a mass fraction of 17%, then raise the temperature to 65°C, stir the reaction for 4h, and cool to room temperature , to obtain intermediate 1;

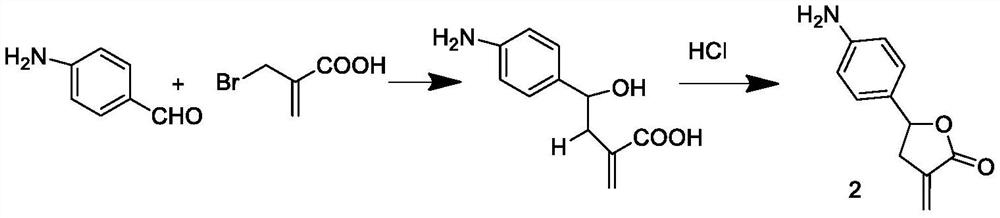

[0029] Step S12, add 1mmol of 4-aminobenzaldehyde, 1.0mmol of 2-(bromomethyl)acrylic acid, 5mL of THF and 5mL of deionized water into the round bottom flask, stir for 3min, add 1.1mmol of indium powder, and stir magnetically , TLC tracking, after the raw material point of aldehyde disappears, add 2 mL of hydrochloric acid solution with a concentration of 6 mol / L and stir for 3 h, extract with ethyl acetate, dry with anhydrous sodium sulfate, filter, and rotary evaporate under reduced pressure to obtain intermediate 2;

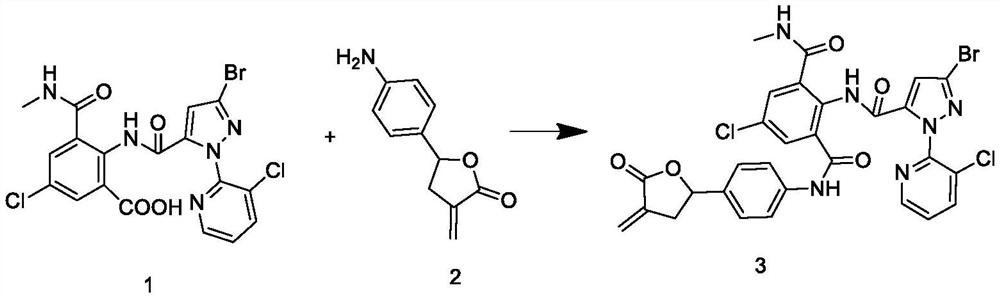

[0030] Step S13, take 50mmol of intermediate 1, 3.2mL of triethylamine and 38mL of tetrahydrofuran in ...

Embodiment 2

[0034] Slow-release insecticides are made by:

[0035] Step S11, add 1.0g of chlorantraniliprole and 26mL of DMF into the reaction kettle, add 0.1g of potassium permanganate and 4mL of hydrochloric acid solution with a mass fraction of 17%, then heat up to 67°C, stir for 4.5h, and cool to At room temperature, intermediate 1 was obtained;

[0036] Step S12, add 1mmol of 4-aminobenzaldehyde, 1.1mmol of 2-(bromomethyl)acrylic acid, 5mL of THF and 7mL of deionized water into a round bottom flask, stir for 3min, add 1.1mmol of indium powder, and stir magnetically , TLC tracking, after the raw material point of aldehyde disappears, add 3 mL of hydrochloric acid solution with a concentration of 6 mol / L and stir for 4 hours, extract with ethyl acetate, dry with anhydrous sodium sulfate, filter, and rotary evaporate under reduced pressure to obtain intermediate 2;

[0037] Step S13, take 50mmol of intermediate 1, 3.5mL of triethylamine and 40mL of tetrahydrofuran in a three-necked fla...

Embodiment 3

[0041] Slow-release insecticides are made by:

[0042] Step S11, add 1.2g of chlorantraniliprole and 28mL of DMF into the reaction kettle, add 0.1g of potassium permanganate and 5mL of hydrochloric acid solution with a mass fraction of 17%, then heat up to 68°C, stir for 5h, and cool to room temperature , to obtain intermediate 1;

[0043] Step S12, add 1mmol of 4-aminobenzaldehyde, 1.2mmol of 2-(bromomethyl)acrylic acid, 5mL of THF and 8mL of deionized water into the round bottom flask, stir for 3min, add 1.1mmol of indium powder, and magnetically stir , TLC tracking, after the raw material point of aldehyde disappears, add 4 mL of hydrochloric acid solution with a concentration of 6 mol / L and stir for 6 hours, extract with ethyl acetate, dry with anhydrous sodium sulfate, filter, and rotary evaporate under reduced pressure to obtain intermediate 2;

[0044] Step S13, take 50mmol of intermediate 1, 3.8mL of triethylamine and 41mL of tetrahydrofuran in a three-necked flask wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com